Preparation and application of polyaniline nanowire/three-dimensional porous graphene electrode material

A graphene electrode and three-dimensional porous technology, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve problems such as poor structural stability, achieve low cost, prevent electrode materials from collapsing, and increase specific surface area and active sites point effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A preparation method of polyaniline nanowire / three-dimensional porous graphene electrode material, comprising the steps of:

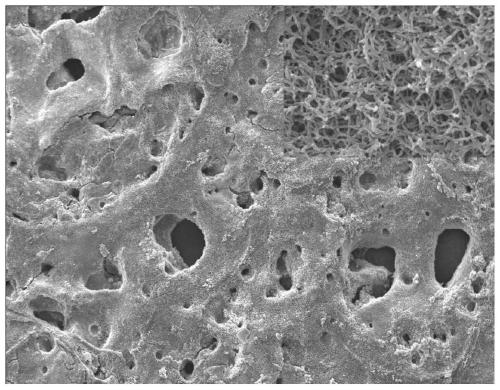

[0052] (1) Hydrothermal reaction: Cut the foamed nickel sheet into 1cm×1cm as the substrate, put the foamed nickel sheet and 0.01moL / l graphene oxide aqueous solution 20mL together in a 50mL hydrothermal reaction kettle, and control the hydrothermal reaction temperature The temperature is 100°C, and the reaction time is 5h. After the reaction, the nickel-based three-dimensional graphene is placed in a vacuum drying environment at 80°C and dried for use;

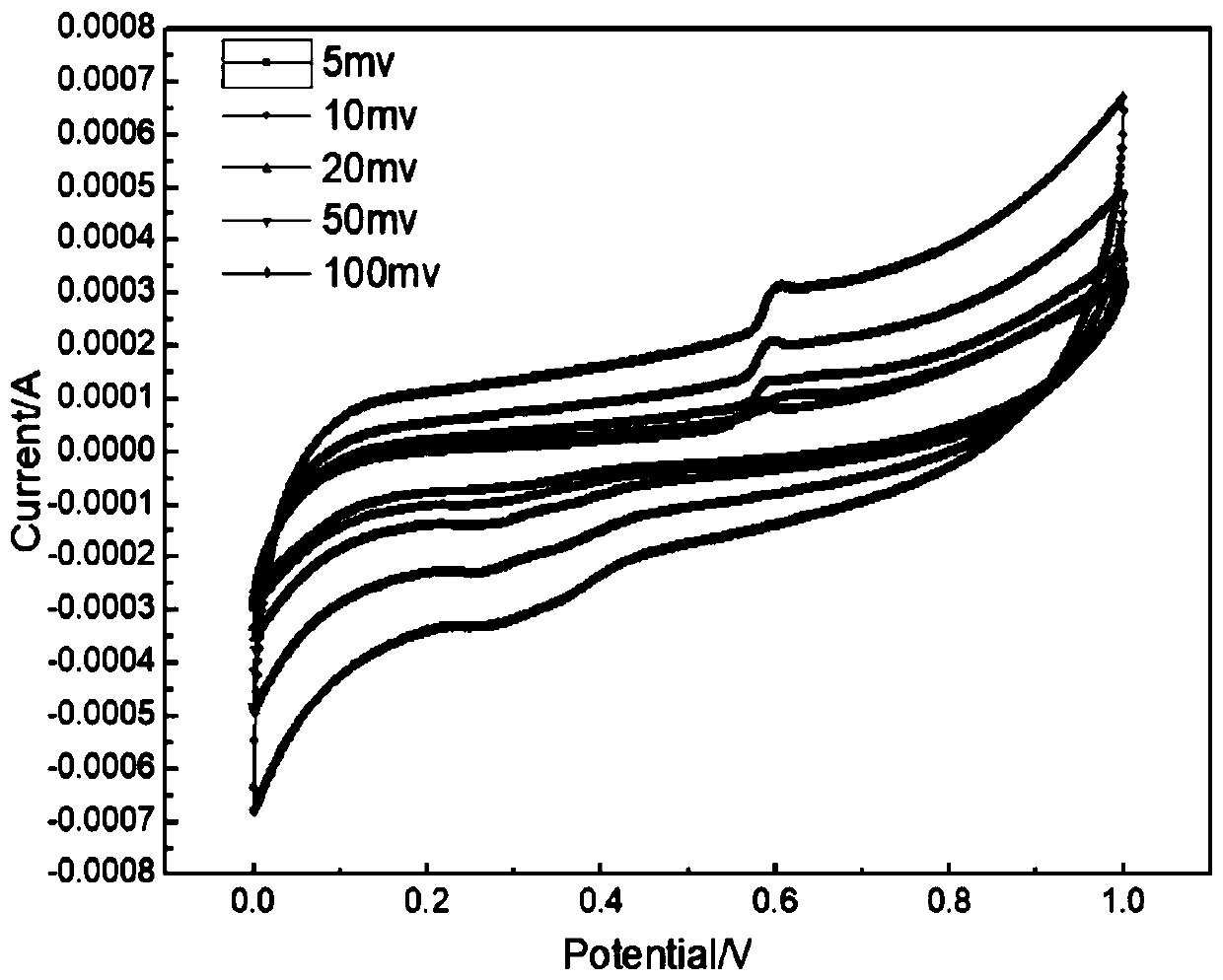

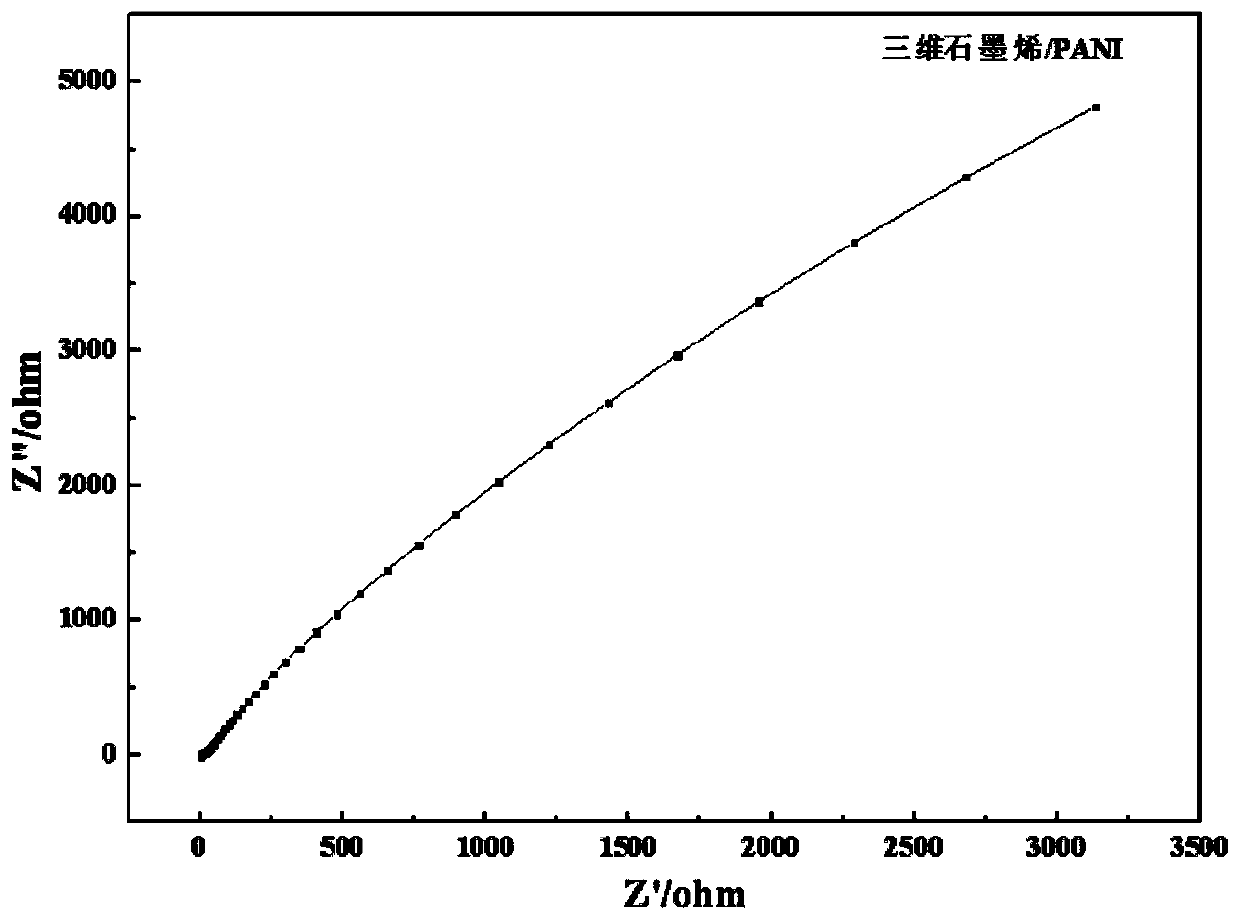

[0053] (2) Electroplating: Dissolve 2g of aniline monomer into 100mL of dilute sulfuric acid with a mass concentration of 20%, and prepare an aniline electroplating solution; a three-electrode system is adopted, with nickel-based three-dimensional graphene as the working electrode, and Ag / AgCl as the counter electrode. The Pt electrode was used as a reference electrode, and was electroplated at ...

Embodiment 2

[0058] A preparation method of polyaniline nanowire / three-dimensional porous graphene electrode material, comprising the steps of:

[0059] (1) Hydrothermal reaction: Cut the foamed nickel sheet into 1cm×1cm as the substrate, put the foamed nickel sheet and 0.5mol / l graphene oxide aqueous solution 20mL together in a 50mL hydrothermal reaction kettle, and control the hydrothermal reaction temperature The temperature is 150°C, and the reaction time is 3h. After the reaction, the nickel-based three-dimensional graphene is placed in a vacuum drying environment of 80°C and dried for use;

[0060] (2) Electroplating: Dissolve 5g of aniline monomer into 100mL of dilute sulfuric acid with a mass concentration of 20%, and prepare an aniline electroplating solution; adopt a three-electrode system, nickel-based three-dimensional graphene is the working electrode, and Ag / AgCl is the counter electrode. The Pt electrode was used as a reference electrode, and was electroplated at a constant ...

Embodiment 3

[0065] A preparation method of polyaniline nanowire / three-dimensional porous graphene electrode material, comprising the steps of:

[0066] (1) Hydrothermal reaction: Cut the foamed nickel sheet into 1cm×1cm as the substrate, place the foamed nickel sheet and 1moL / l graphene oxide aqueous solution 20mL together in a 50mL hydrothermal reaction kettle, and control the hydrothermal reaction temperature. 300°C, the reaction time is 0.5h. After the reaction, the nickel-based three-dimensional graphene is dried in a vacuum drying environment at 80°C for use;

[0067] (2) Electroplating: Dissolve 8g of aniline monomer into 100mL of dilute sulfuric acid with a mass concentration of 20%, and prepare an aniline electroplating solution; adopt a three-electrode system, nickel-based three-dimensional graphene is the working electrode, and Ag / AgCl is the counter electrode. The Pt electrode was used as a reference electrode, and was electroplated at a constant voltage of 0.6V for 10 minutes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com