Sintering flue gas multipollutant collaborative purification and waste heat utilization system and process

A technology for sintering flue gas and pollutants, applied in incinerators, combustion types, gas treatment, etc., can solve the problems of large fuel consumption, break the supply balance of the factory area, and occupy a large area, so as to increase the height of equipment and save gas consumption , high purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings.

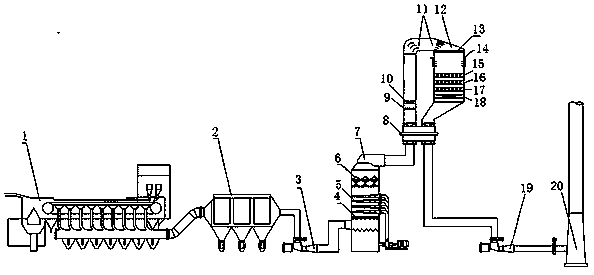

[0046] Such as figure 1 As shown, a sintering flue gas multi-pollutant co-processing and waste heat utilization system and process consists of sintering machine 1, high-efficiency bag filter 2, main exhaust fan 3, high-efficiency wet desulfurization device 7, and GGH flue gas heat exchanger 8 , a catalytic denitrification, deCO2 and waste heat utilization integrated device 12 , a booster fan 19 and a chimney 20 .

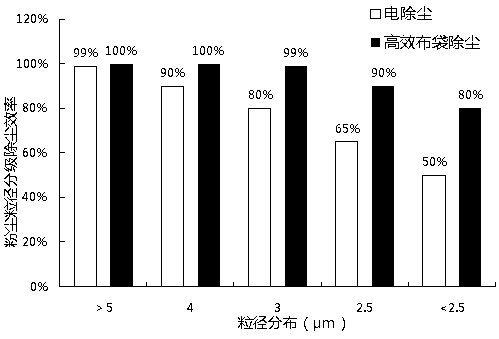

[0047] The flue gas produced by sintering machine 1 enters the high-efficiency bag filter 2 through the bottom header. The dust concentration is 3~5g / Nm 3 Reduced to 20mg / Nm 3 At the same time, the particle size less than 2.5μm has a purification efficiency of more than 80%, and the fine dust entering the desulfurization tower is less, creating favorable conditions for downstream wet desulfurization and dust removal, such as figure 2 shown.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com