Preparation method and application of porous graphene film

A porous graphene, graphene technology, applied in graphene, chemical instruments and methods, inorganic chemistry and other directions, can solve problems such as lack of market competitiveness of products, and achieve good application prospects, good conductivity, and good market prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

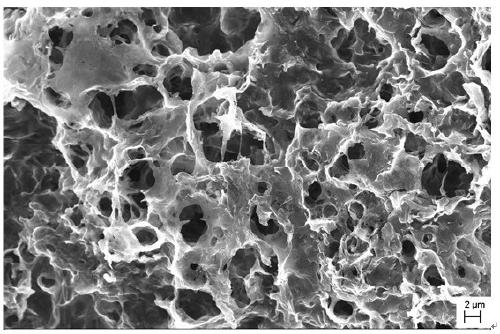

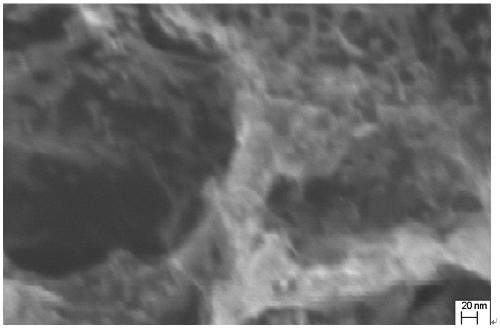

[0031] The graphene film obtained in this embodiment is a graphene film with a three-dimensional porous structure inside, and its preparation steps are as follows:

[0032] S1. Preparation of precursor mixture

[0033] Mix iron oxide, mesophase pitch and water uniformly to prepare a precursor mixture, and the weight ratio of the three is 3:3:10.

[0034] S2. Forming the mixture film layer prepared in step S1 on the substrate, which can be uniformly coated by casting method or coating method, and the thickness is adjustable;

[0035] S3, drying to remove the solvent in the mixture to form the embryonic membrane, it should be noted that the drying temperature is less than 50 ° C, preferably naturally drying;

[0036] S4, in situ catalyzing the carbon in the carbon precursor to generate graphene;

[0037] This step is a key step of this method. The in-situ generation of graphene is realized by heat treatment. The heat treatment temperature is 600-1000°C, and the heat treatment ...

Embodiment 2

[0041] The preparation method of the present embodiment is similar to that of Example 1, the difference mainly lies in the raw materials, and the specific preparation steps are as follows:

[0042] S1. Preparation of precursor mixture

[0043] Mix nickel oxide, mesophase pitch and acetone uniformly to prepare a precursor mixture, and the weight ratio of the three is 4:3:8.

[0044] S2, forming the mixture film layer prepared in step S1 on the substrate;

[0045] S3, drying naturally to remove the solvent in the mixture to form the embryonic membrane;

[0046] S4. In a protective atmosphere, heat the embryo membrane to 600°C for 10 hours, then raise the temperature to 900°C for 10 hours, and catalyze the carbon in the carbon precursor to generate graphene in situ;

[0047] S5. Using acetic acid solution as a template-releasing agent, removing the template and drying to obtain a porous graphene membrane.

[0048] After testing, the thickness of the graphene film of this embod...

Embodiment 3

[0050] The preparation method of this embodiment is similar to that of Example 2, the difference mainly lies in the use of different templating agents, and the specific preparation steps are as follows:

[0051] S1. Preparation of precursor mixture

[0052] Mix ferric chloride, ammonia water, mesophase pitch and acetone evenly to prepare a precursor mixture, and the weight ratio of the four is 3:3:3:10.

[0053] S2, forming the mixture film layer prepared in step S1 on the substrate by spin coating;

[0054] S3, drying naturally to remove the solvent in the mixture to form the embryonic membrane;

[0055] S4. In a protective atmosphere, raise the temperature of the embryo membrane to 1000°C for 15 hours, and catalyze the carbon in the carbon precursor to generate graphene in situ;

[0056] S5. Using acetic acid solution as a template-releasing agent, removing the template and drying to obtain a porous graphene membrane.

[0057] After testing, the thickness of the graphene fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com