Synthetic process of polymeric ferric sulfate flocculant

A technology for polymerizing ferric sulfate and synthesis process, which is applied in the fields of ferric sulfate, flocculation/sedimentation water/sewage treatment, chemical instruments and methods, etc. It can solve the problems of reducing the purity of polymerized ferric sulfate flocculants, and achieve excellent treatment effect and scope of application. Wide and less corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

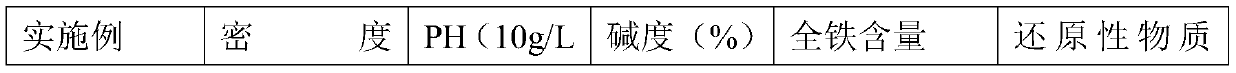

Examples

Embodiment 1

[0031] Use the process of the present invention to prepare polymeric ferric sulfate flocculant:

[0032] (1) Use the "four-chamber" structure of the electrodialysis membrane stack to process the saturated solutions of ferrous sulfate and potassium chlorate. The two desalination chambers are added with ferrous sulfate solution and potassium chlorate solution, and the concentration chamber is filled with deionized water. When the voltage starts to rise, the reaction is completed for about 30 minutes to prepare high-concentration Fe 2+ With ClO 3 - The volume ratio of ferrous sulfate saturated solution, potassium chlorate saturated solution and deionized water is 1:1:1.

[0033] (2) Add the solution prepared in step (1) to the salt chamber of the bipolar membrane electrodialysis membrane stack. The initial solutions of the acid chamber and the alkali chamber are deionized water, and the bipolar membrane electrodialysis electrode solution is 3% by mass. Na 2 SO 4 The solution, the thre...

Embodiment 2

[0036] Use the process of the present invention to prepare polymeric ferric sulfate flocculant:

[0037] (1) Use the "four-chamber" structure of the electrodialysis membrane stack to process the saturated solutions of ferrous sulfate and potassium chlorate. The two desalination chambers are added with ferrous sulfate solution and potassium chlorate solution, and the concentration chamber is filled with deionized water. When the voltage starts to rise, the reaction is completed for about 30 minutes to prepare high-concentration Fe 2+ With ClO 3 - The volume ratio of ferrous sulfate saturated solution, potassium chlorate saturated solution and deionized water is 1:1:1.

[0038] (2) Add the solution prepared in step (1) to the salt chamber of the bipolar membrane electrodialysis membrane stack. The initial solutions of the acid chamber and the alkali chamber are deionized water, and the bipolar membrane electrodialysis electrode solution is 3% by mass. Na 2 SO 4 The solution, the thre...

Embodiment 3

[0041] Use the process of the present invention to prepare polymeric ferric sulfate flocculant:

[0042] (1) Use the "four-chamber" structure of the electrodialysis membrane stack to process the saturated solutions of ferrous sulfate and potassium chlorate. The two desalination chambers are added with ferrous sulfate solution and potassium chlorate solution, and the concentration chamber is filled with deionized water. When the voltage starts to rise, the reaction is completed for about 30 minutes to prepare high-concentration Fe 2+ With ClO 3 - The volume ratio of ferrous sulfate saturated solution, potassium chlorate saturated solution and deionized water is 1:1:1.

[0043] (2) Add the solution prepared in step (1) to the salt chamber of the bipolar membrane electrodialysis membrane stack. The initial solutions of the acid chamber and the alkali chamber are deionized water, and the bipolar membrane electrodialysis electrode solution is 3% by mass. Na 2 SO 4 The solution, the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com