Method for separating coenzyme Q10 by using supercritical fluid chromatography system

A supercritical fluid and chromatographic system technology, applied in the field of material separation and purification, can solve the problems of low purity and yield of coenzyme Q10 crude extract, large solvent consumption, long time consumption, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0039] According to a specific embodiment of the present invention, the method for utilizing a supercritical fluid chromatography system to separate coenzyme Q10 includes:

[0040] (1) dissolving the coenzyme Q10 crude extract in an organic solvent to prepare the coenzyme Q10 feed liquid to be separated; turn on the supercritical fluid chromatography system, and set the system parameters;

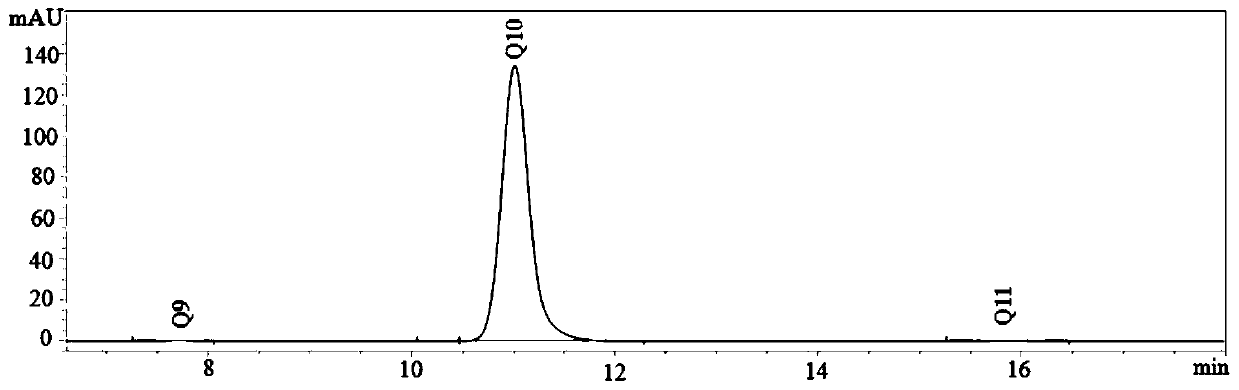

[0041] (2) After the system runs stably, the chromatographic column is fully balanced, and the baseline is stable, inject the coenzyme Q10 feed solution to be separated, collect the coenzyme Q10 components according to the ultraviolet peak signal of the peak, and repeat the sample injection several times according to this separation process ;

[0042] (3) Use a rotary evaporator to remove the organic solvent and entrainer from the coenzyme Q10 fraction collected in the above steps to obtain high-purity coenzyme Q10.

[0043] The present invention will be described in detail below by way of...

Embodiment 1

[0046] In this embodiment, the chromatographic column specification is 10×250 mm, the stationary phase is C18, and the particle size is 25 μm. The method for separating coenzyme Q10 by a supercritical fluid chromatography system includes the following steps:

[0047] (1) Dissolve the crude extract of coenzyme Q10 in methanol to make coenzyme Q10 feed solution, the concentration is 0.5mg·mL -1 , the purity is 45%; open the supercritical fluid chromatography system, set the column temperature of its chromatographic column to be 30 ℃, the column pressure to be 7MPa, and the column pressure is a constant pressure, the mobile phase flow rate is 6CV / min, and the mobile phase is composed of supercritical carbon dioxide and an entrainer, the entrainer is ethanol and the proportion of the entrainer in the mobile phase is 5% v / v, and the ultraviolet wavelength is 220nm;

[0048] (2) After the system runs stably, the chromatographic column is fully balanced, and the baseline is stable, i...

Embodiment 2

[0051] In this example, the size of the chromatographic column is 15×250 mm, the stationary phase is silica gel coated with tris(3,5-dimethylphenylcarbamoylated) amylose, and the particle size is 45 μm. The supercritical fluid chromatography system separates the coenzyme The method of Q10 includes the following steps:

[0052] (1) Dissolve the crude extract of coenzyme Q10 in ethanol to make coenzyme Q10 feed solution, the concentration is 5mg·mL -1 , the purity is 52%; open the supercritical fluid chromatography system, set the column temperature of its chromatographic column to be 35°C, the column pressure to be 8.5MPa, and the column pressure to be a constant pressure, the mobile phase flow rate to be 5CV / min, and the mobile phase to be composed of supercritical Composed of carbon dioxide and an entrainer, the entrainer is isopropanol and the proportion of the entrainer in the mobile phase is 10% v / v, and the ultraviolet wavelength is 245nm;

[0053] (2) After the system i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com