Electrode for lithium battery, preparation method thereof, and lithium battery containing the electrode

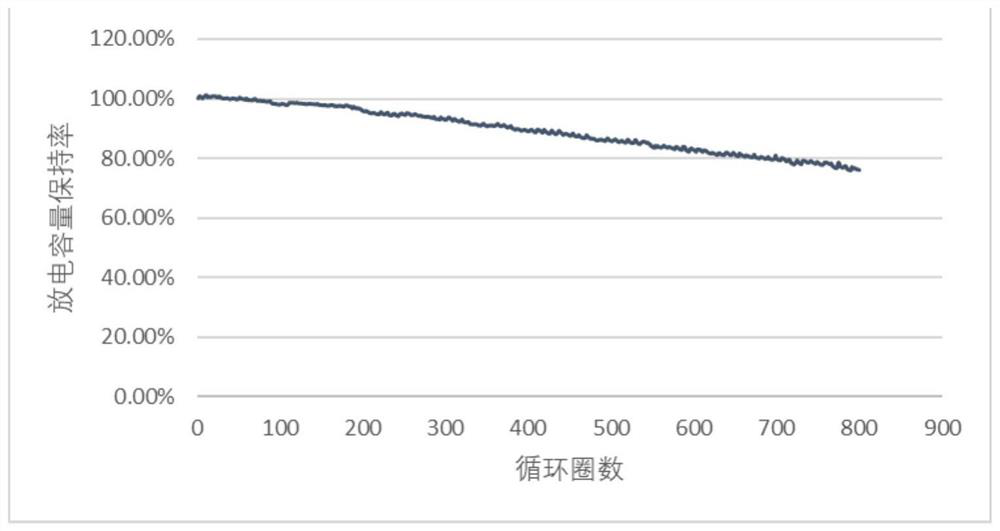

A lithium battery and electrode technology, which is applied in the field of electrodes and their preparation methods and lithium batteries containing the electrode, can solve the problems of conformality/inhibition of volume change, battery capacity attenuation, SEI film thickening, etc. at the same time, to achieve Inhibit the cracking of the pole piece, reduce the consumption of electrolyte, and improve the effect of cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] One embodiment of the present invention also provides the preparation method of above-mentioned lithium battery electrode, it comprises the following steps:

[0044] (1) dissolving / dispersing the material of the electrochemical active layer in solvent A to obtain active material slurry; meanwhile, dissolving the lithium ion exchange polymer in solvent B to obtain polymer glue;

[0045] (2) Coating the active material slurry and the polymer glue on the current collector by simultaneous coating, wherein the active material slurry is below (close to the current collector) and the polymer glue is above; or Firstly, the active material slurry is coated on the current collector, and after drying and rolling, the current collector with the active material coating is immersed in the polymer glue or the polymer glue is coated on the active material coating. on the current collector of the layer;

[0046] (3) performing drying treatment to obtain the electrode for the lithium ba...

Embodiment 1

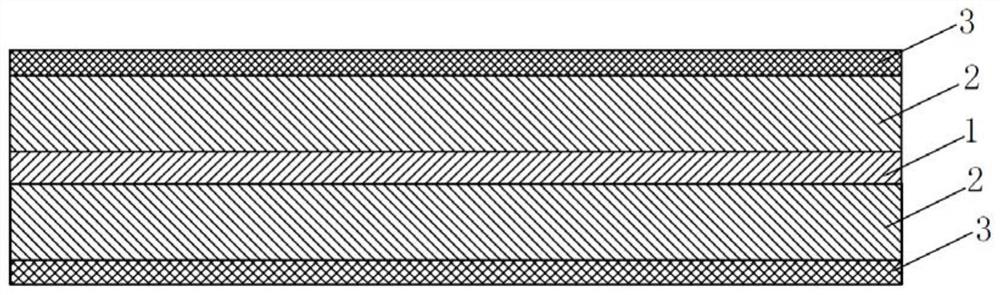

[0052] Such as figure 1 As shown, an electrode for a lithium battery according to an embodiment of the present invention includes a current collector 1, an electrochemically active layer 2 disposed on the current collector 1, and a modification layer 3 coated on the outer surface of the electrochemically active layer 2; Wherein, the current collector 1 is made of battery-grade copper foil; the electrochemically active layer 2 is made of the following components by weight percentage: 95% silicon-based negative electrode material, 4% binder, and 1% conductive agent; The modification layer 3 is formed of a lithium ion exchange polymer, and the lithium ion exchange polymer is nafion-Li.

[0053] In the lithium battery electrode of this embodiment, the porosity of the modified layer 3 is 5%, and the thickness of the modified layer 3 is 500 nm.

[0054] The preparation method of the lithium battery electrode of the present embodiment is:

[0055] (1) dissolving / dispersing the mate...

Embodiment 2

[0062] An electrode for a lithium battery according to an embodiment of the present invention. The structure of the electrode for a lithium battery described in this embodiment is the same as that in Embodiment 1, specifically as follows figure 1 shown. The electrode for the lithium battery described in this embodiment is different from the electrode for the lithium battery described in Embodiment 1 only in that: in this embodiment, the material of the current collector 1 is a carbon-coated foil material; the material of the electrochemically active layer 2 is made of The following components are composed in weight percent: 90% of tin-based negative electrode material, 8% of binder, and 2% of conductive agent; the modification layer 3 is formed by lithium ion exchange polymer, and the lithium ion exchange polymer is nafion-Li.

[0063] In the lithium battery electrode of this embodiment, the porosity of the modified layer 3 is 3%, and the thickness of the modified layer 3 is 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com