A kind of polarizing plate waste liquid treatment method

A waste liquid treatment and polarizing plate technology, which is applied in chemical instruments and methods, alkali metal halide purification, boron oxides, etc., can solve the problem of high requirements for precise control of concentration ratio, large calcium hydroxide, large consumption of acid and alkali, etc. problems, to achieve the effect of high industrial application prospects, low energy consumption and cost, and high economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

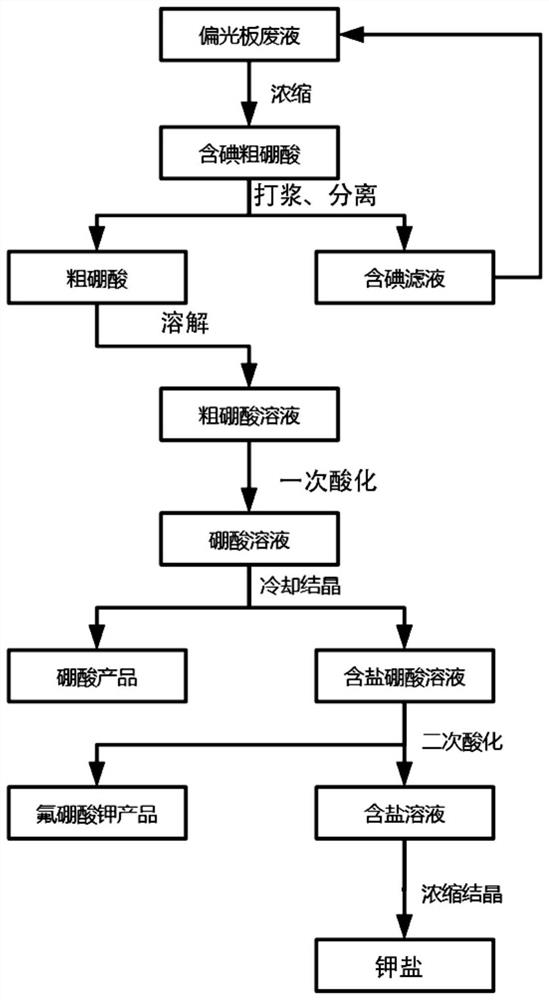

Method used

Image

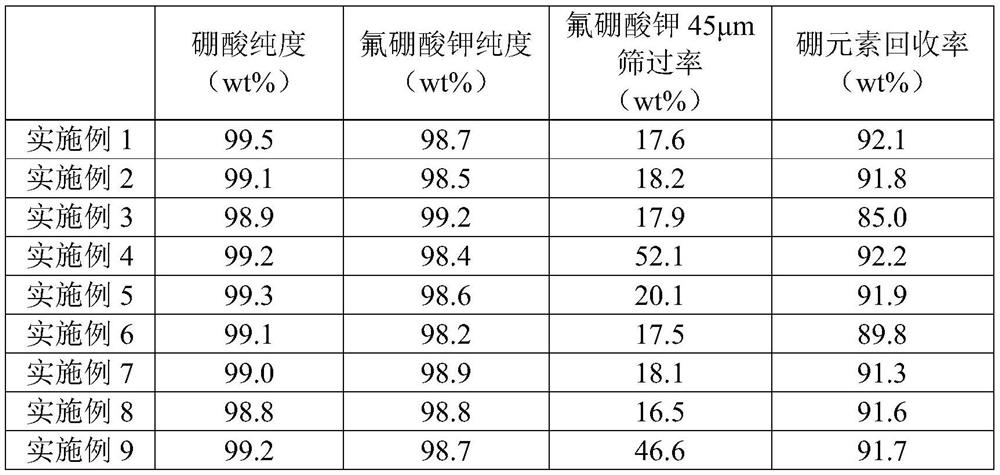

Examples

Embodiment 1

[0079] This embodiment provides a method for processing polarizer waste liquid, the method comprising the following steps:

[0080] (1) 2L of polarizing plate waste liquid is distilled and concentrated under the condition of 100°C and -0.07MPa to obtain 200g of iodine-containing crude boric acid, and 70mL of potassium sulfite mass concentration is 0.7g / L potassium sulfite is added to the iodine-containing crude boric acid. The solution is used as a beating solution, and a beating process is performed. The beating process is repeated twice, filtered and separated to obtain crude boric acid and an iodine-containing solution. It is detected that the crude boric acid after beating does not contain potassium iodide, and the iodine-containing solution is returned to the polarizing plate waste liquid. , the iodine-containing crude boric acid includes 74 wt % of boric acid, 21 wt % of potassium tetraborate, 0.32 wt % of potassium iodide and 0.67 wt % of iodine by mass fraction;

[008...

Embodiment 2

[0085] The present embodiment provides a method for processing polarizer waste liquid, the method comprising the following steps:

[0086] (1) 4L of polarizing plate waste liquid was distilled and concentrated at 90°C and -0.08MPa to obtain 400g of iodine-containing crude boric acid, adding 140mL of potassium sulfite mass concentration to iodine-containing crude boric acid to be 0.7g / L of potassium sulfite The solution is used as a beating solution, and a beating process is performed. The beating process is repeated twice, filtered and separated to obtain crude boric acid and an iodine-containing solution. It is detected that the crude boric acid after beating does not contain potassium iodide, and the iodine-containing solution is returned to the polarizing plate waste liquid. , the iodine-containing crude boric acid includes 69 wt % of boric acid, 27 wt % of potassium tetraborate, 0.61 wt % of potassium iodide and 0.33 wt % of iodine by mass fraction;

[0087] (2) slowly add...

Embodiment 3

[0091] The present embodiment provides a method for processing polarizer waste liquid, the method comprising the following steps:

[0092] (1) 2L polarizing plate waste liquid is distilled and concentrated under the condition of 120 DEG C and -0.05MPa to obtain 200g iodine-containing crude boric acid, and adding 60mL potassium sulfite mass concentration to the iodine-containing crude boric acid is a potassium sulfite solution of 1g / L Make beating liquid, carry out beating treatment, described beating treatment is repeated 2 times, filter and separate to obtain crude boric acid and iodine-containing solution, detect that the crude boric acid after beating does not contain potassium iodide, and the iodine-containing solution is returned to the polarizing plate waste liquid , the iodine-containing crude boric acid includes 80wt% of boric acid, 15wt% of potassium tetraborate, 0.76wt% of potassium iodide and 0.12wt% of iodine by mass fraction;

[0093] (2) slowly adding the describ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com