Purification method of copper electrolyte

A copper electrolyte and electrolyte technology, applied in the field of metallurgy, can solve the problems of high loss, time-consuming and laborious, and poor stability of resin impurity removal by concentration method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

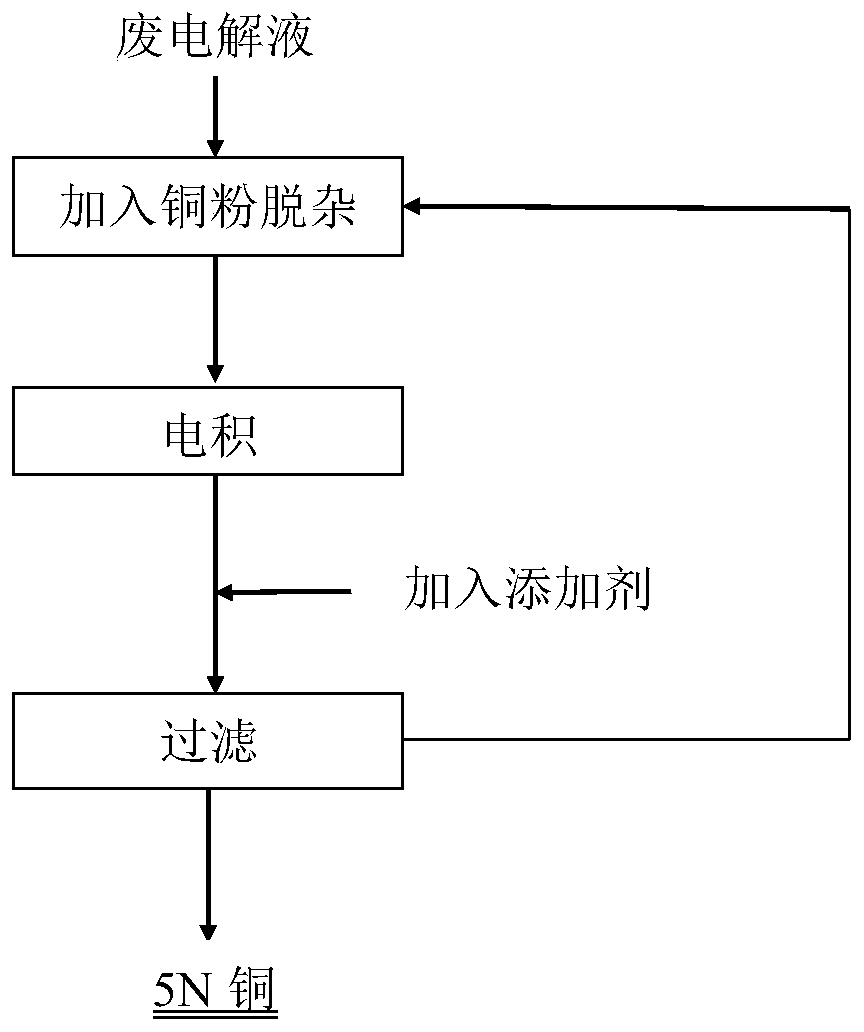

Method used

Image

Examples

Embodiment 1

[0045] Take Cu 2+ Concentration is 100g / L waste copper nitrate electrolyte 40L, after heating to electrolyte temperature 35 ℃, add 500 meshes of purified copper powder (100*the amount of (As+Sb+Bi+Pb+Ag) in the solution) 464g, cycle Electrowinning was carried out after 6 hours of reaction, and the current density was controlled to be 150A / m 2 , the electrodeposition temperature is 35°C, and the electrodeposition time is 24h.

[0046] Electrolyte composition after purification in the embodiment of the present invention 1 in table 1

[0047] name Electrolyte (before electrowinning) Electrolyte (12h after electrowinning) Electrolyte (24h after electrowinning) Cu 2+ / g / L

102 90.4 81.5 HNO 3 / g / L

4.2 9.2 13.4 Ag / mg / L 5 <0.5

<0.5

As / mg / L 20 10 9.3 Sb / mg / L 15 9 8.1 Bi / mg / L 16 8 7.5 Pb / mg / L 60 40 38

[0048] Content of cathode copper element in table 2 embodiment 1 of the present invention

[00...

Embodiment 2

[0051] Take Cu 2+ 40L of copper nitrate electrolyte with a concentration of 150g / L, heated to the temperature of the electrolyte at 30°C, and then adding 579.6g of 600-mesh copper powder (the amount of (As+Sb+Bi+Pb+Ag) in the 115* solution) to control the current The density is 150A / m 2 , the electrodeposition temperature is 30°C, and the electrodeposition time is 24h.

[0052] Electrolyte composition after purification in the embodiment of the present invention 2 in table 3

[0053] name Electrolyte (before electrowinning) Electrolyte (12h after electrowinning) Electrolyte (24h after electrowinning) Cu 2+ / g / L

152 128.3 113.2 HNO 3 / g / L

8.5 14.1 18.6 Ag / mg / L 8 <0.5

<0.5

As / mg / L 22 9.8 9.0 Sb / mg / L 17 8.7 7.9 Bi / mg / L 17 7.8 7.3 Pb / mg / L 62 40 37

[0054] Content of cathode copper element in table 4 embodiment 2 of the present invention

[0055] Cu% Ag% S% Fe% Pb% As% S...

Embodiment 3

[0057] Take Cu 2+ Two parts of 40L of copper nitrate electrolyte with a concentration of 100g / L were heated to the temperature of the electrolyte at 33°C, and copper powder of 500 mesh and 1000 mesh were added respectively (110*the amount of (As+Sb+Bi+Pb+Ag) in the solution )510.4g, the control current density is 160A / m 2 , the electrodeposition temperature is 33°C, and the electrodeposition time is 24h.

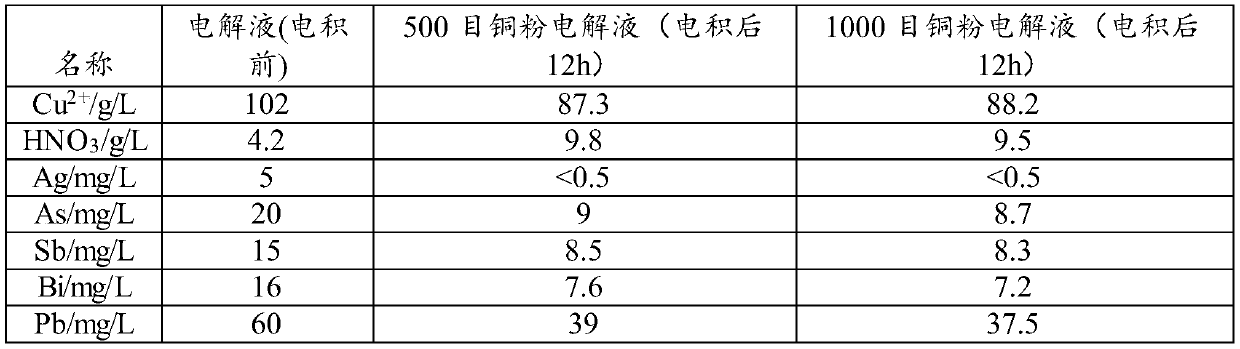

[0058] Electrolyte composition after purification in different granularity embodiments of table 5

[0059]

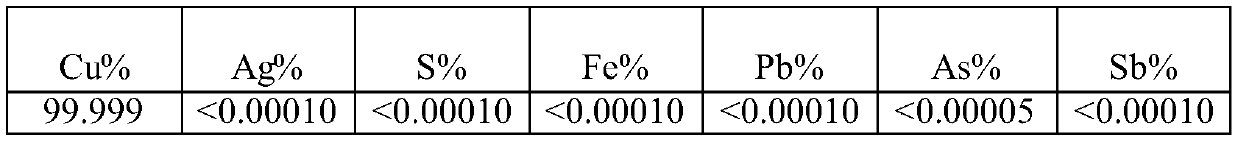

[0060] Cathode copper element content in different particle size embodiments of table 6

[0061]

[0062]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com