Ketogenic energy bar containing high-quality nuts and preparation method of ketogenic energy bar

An energy bar and ketogenic technology, which is applied in the field of food processing, can solve problems such as ignorance of nutritional elements, insufficient intake of nutrients, and too greasy taste of ketogenic energy bars, and achieve the effects of avoiding dizziness, improving taste, and prolonging residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

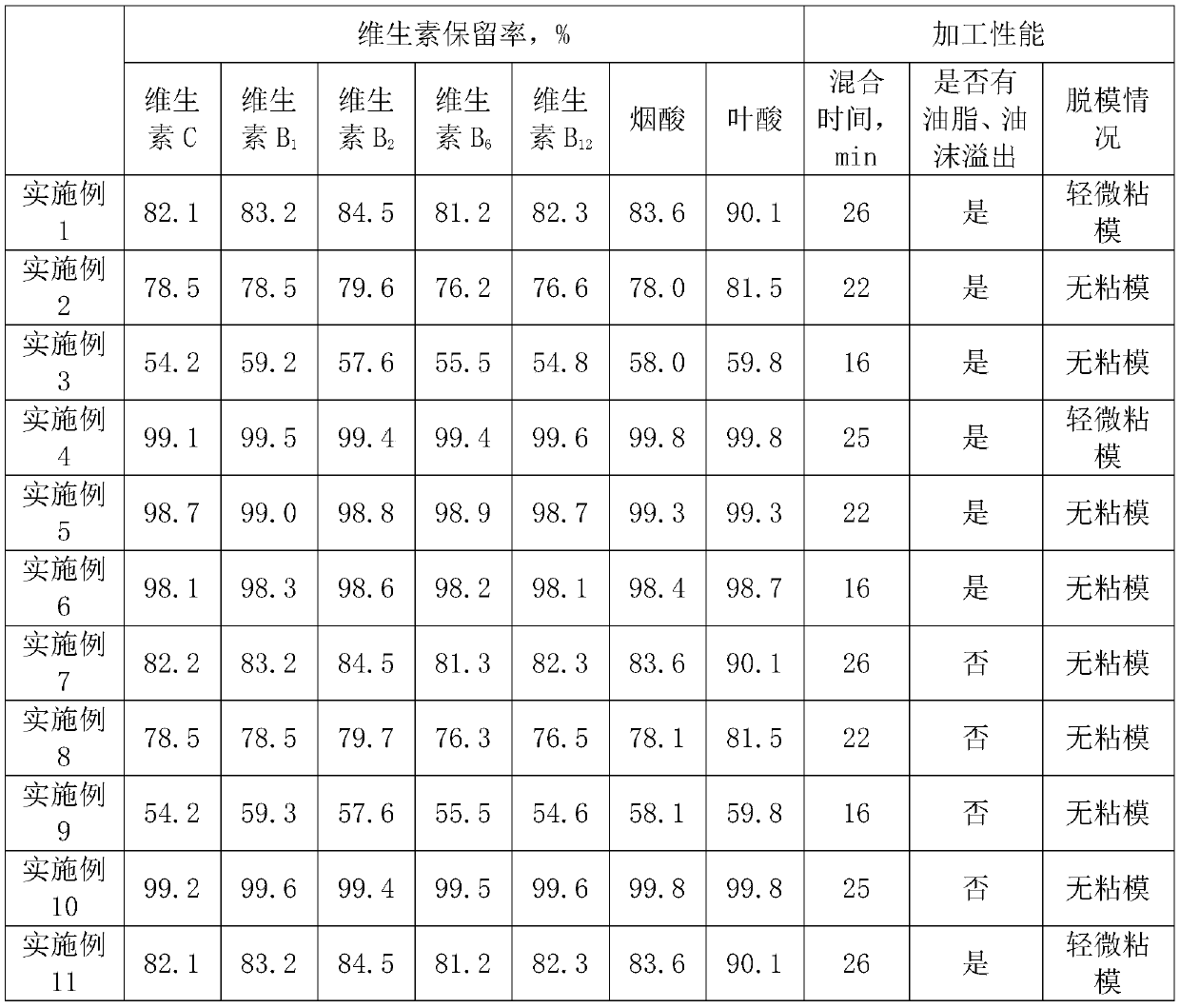

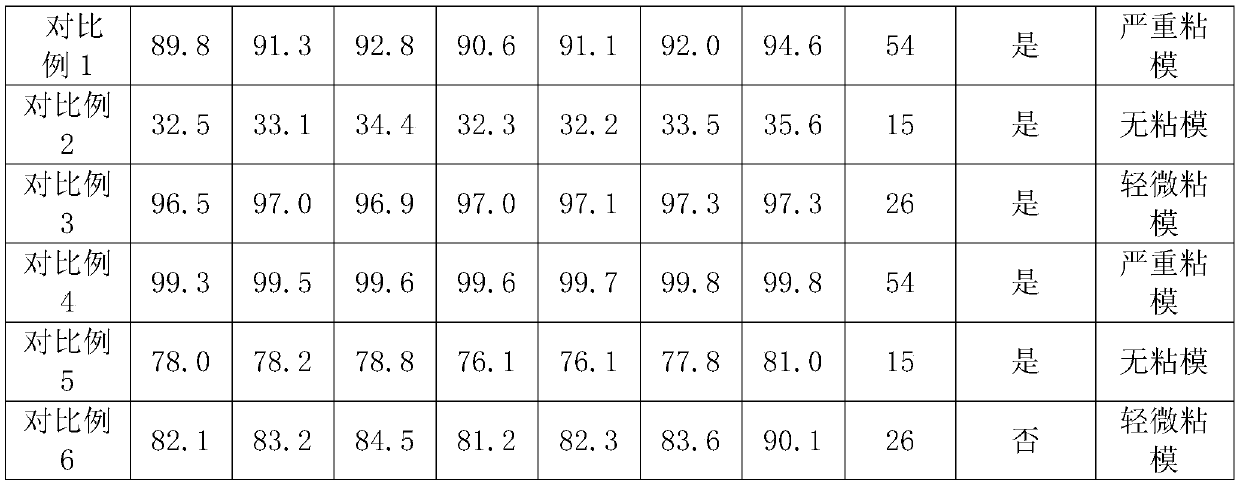

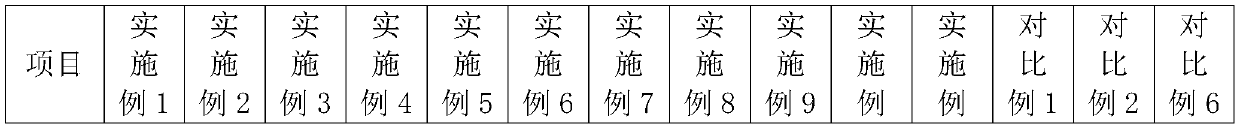

Examples

preparation example

[0042] The raw materials in the following preparation examples are all food grade.

[0043] Preparation example 1 of anti-adhesive glue: take 200kg of water, heat it to 700°C, add 30kg of konjac glucomannan, 6kg of corn modified starch, 3kg of glycerin, 3kg of gelatin, 3kg of pectin, β-ring Dextrin 3kg, oleic acid glyceride 2kg, diacetyl tartaric acid mono-diglyceride 1kg, xylitol 0.4kg and tea polyphenol 0.2kg, with the speed of 2000r / min, heat preservation and stirring for 10min, then heat preservation 1h after degassing, obtained Anti-stick glue.

[0044] Preparation example 2 of anti-adhesive glue solution: take 250kg of water, heat it to 75°C, add 35kg of konjac glucomannan, 7kg of corn modified starch, 4kg of glycerin, 4kg of gelatin, 4kg of pectin, β-ring Dextrin 4kg, oleic acid glyceride 3kg, diacetyl tartaric acid mono-diglyceride 1.5kg, xylitol 0.5kg and tea polyphenol 0.3kg, at the speed of 2500r / min, heat preservation and stirring for 15min, then heat preservation...

preparation example 4

[0046] Preparation Example 4 of anti-adhesive glue: The difference between this preparation example and Preparation Example 1 of anti-adhesive glue is that no pectin, 3 kg of glyceryl oleate, diacetyl tartaric acid mono-diglycerides and tea polysaccharides are added in the raw materials. phenol.

Embodiment 1

[0049] Example 1: A ketogenic energy bar containing high-quality nuts is prepared by the following method:

[0050] S1. Take 15kg of pumpkin seeds, 1.5kg of superfine minced coconut, 5kg of collagen powder, 18kg of fat microcapsule powder, 0.0001kg of vitamin A, 0.000001kg of vitamin D, 0.007kg of vitamin E, 0.05kg of vitamin C, and vitamin B 1 0.001kg, vitamin B 2 0.001kg, vitamin B 6 0.001kg, vitamin B 12 0.0000005kg, niacin 0.01kg, folic acid 0.0001kg, calcium 0.0001kg, iron 0.003kg and zinc 0.003kg, mixed evenly to obtain powder;

[0051] S2. Take 0.1kg of table salt, 5kg of isomaltooligosaccharide syrup, 5kg of resistant dextrin, 2kg of glycerin, 10kg of cocoa butter, 5kg of chocolate and 0.1kg of phospholipid, and mix them to obtain a slurry;

[0052] S3, heating the slurry at 90°C, and stop heating when the sugar content of the slurry is 73brix;

[0053] S4. After the slurry is cooled to 60°C, powder is added to the slurry, and the mixture is obtained after insulate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com