Preparation method of lignin-based flexible nano carbon fiber self-supporting electrode material

A technology of nano-carbon fiber and self-supporting electrode, which is applied in fiber processing, nanotechnology, nanotechnology, etc., can solve the problems of complex assembly process of energy storage device, brittleness of nano-carbon fiber, low utilization rate of lignin, etc., and achieve excellent energy storage properties, good flexibility, and the effect of reducing the internal resistance of electrodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] The preparation method of the above-mentioned lignin-based flexible nano-carbon fiber self-supporting electrode material specifically includes the following steps:

[0064] Step 1: Dissolve polyacrylonitrile in a mixed solvent of dimethyl sulfoxide and N,N-dimethylformamide, stir for 2 hours with a magnetic stirrer until the solution is clear, add alkaline lignin, and continue stirring for 7 hours , wherein the volume ratio of dimethyl sulfoxide to N,N-dimethylformamide is 6:4, and the mass ratio of alkaline lignin to polyacrylonitrile is 9:1; mix evenly to make a mass ratio concentration of 30 %, the viscosity is the precursor solution of 3Pa s;

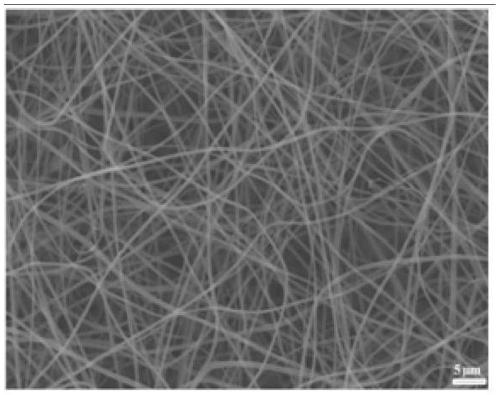

[0065] Step 2: The above-mentioned precursor solution prepared in step 1 is made into a precursor composite nanofiber film through an electrospinning process; the parameters of the electrospinning process: the spinning temperature is 30°C, the relative humidity is 32RH%, and the spinning voltage It is 25kV, the perfusion rat...

Embodiment 2

[0070] The preparation method of the above-mentioned lignin-based flexible nano-carbon fiber self-supporting electrode material specifically includes the following steps:

[0071] Step 1: Dissolve polyvinylidene fluoride in a mixed solvent of dimethyl sulfoxide and N,N-dimethylformamide, stir for 5 hours with a magnetic stirrer until the solution is clear, add sodium lignosulfonate, and continue Stir for 10 hours, wherein the volume ratio of dimethyl sulfoxide to N,N-dimethylformamide is 7:3, and the mass ratio of sodium lignosulfonate to polyvinylidene fluoride is 8:2; mix evenly to make a uniform A stable precursor solution with a mass ratio concentration of 28% and a viscosity of 2.5 Pa s;

[0072] Step 2: The above precursor solution prepared in step 1 is made into a precursor composite nanofiber film through an electrospinning process; the parameters of the electrospinning process: the spinning temperature is 40°C, the relative humidity is 25RH%, and the spinning voltage ...

Embodiment 3

[0076] The preparation method of the above-mentioned lignin-based flexible nano-carbon fiber self-supporting electrode material specifically includes the following steps:

[0077] Step 1: Dissolve polylactic acid in a mixed solvent of dimethyl sulfoxide and N,N-dimethylformamide, stir for 4 hours with a magnetic stirrer until the solution is clear, add hydroxylated alkali lignin, and continue stirring for 9 hours , wherein the volume ratio of dimethyl sulfoxide to N,N-dimethylformamide is 9:1, and the mass ratio of hydroxylated alkali lignin to polylactic acid is 9:1; mix uniformly to make a uniform and stable mass ratio A precursor solution with a concentration of 35% and a viscosity of 4Pa·s;

[0078] Step 2: The above precursor solution prepared in step 1 is made into a precursor composite nanofiber membrane through an electrospinning process. Electrospinning process parameters: the spinning temperature is 37°C, the relative humidity is 28RH%, the spinning voltage is 30kV,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com