Preparation method of composite material for polyurethane water-based coating

A technology of water-based coatings and composite materials, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of large specific surface area, low adsorption activity, and poor thermal stability of nano-graphene, and achieve good thermal stability and affinity Good performance and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

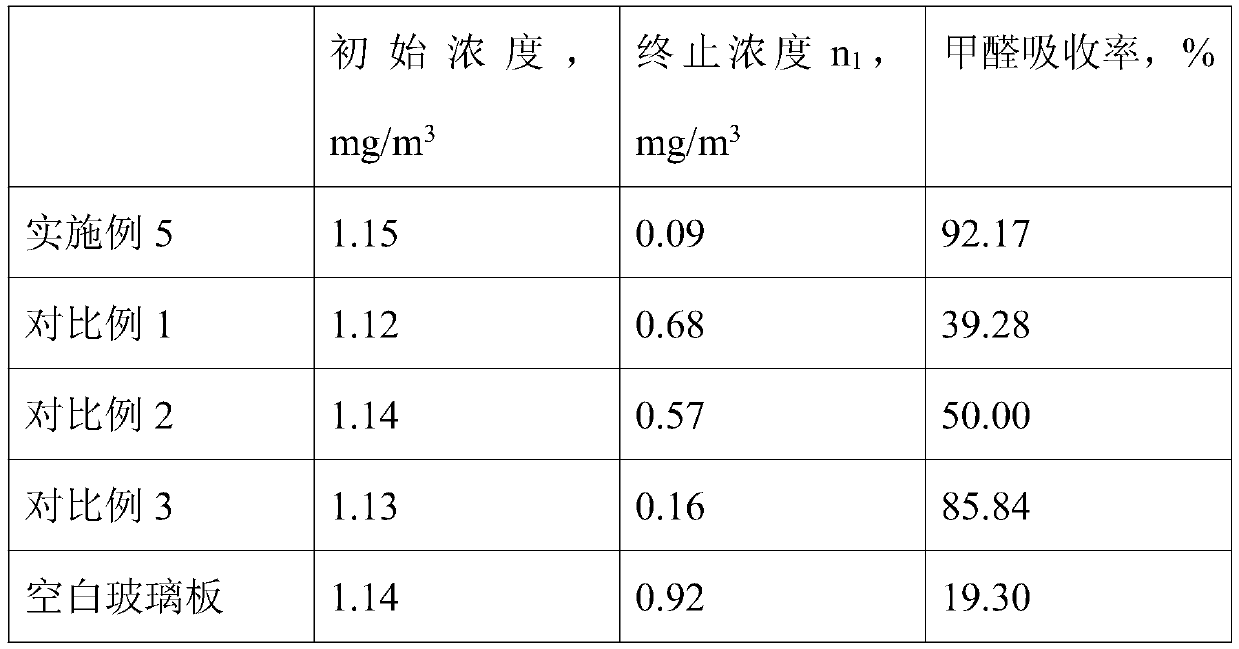

Examples

Embodiment 1

[0028] A preparation method for a composite material for polyurethane water-based paint, comprising the steps of:

[0029] S1. Ultrasonically disperse 5kg of nano-graphene oxide in 60kg of water. The particle size of nano-graphene oxide is 10-200nm, and the thickness of the sheet is 0.1-1nm. The ultrasonic power is 400W, and then 3kg of hydrazine hydrate is added. Reflux reaction for 30h, continue to add 1kg aminophenylacetic acid, 0.5kg isoamyl nitrite, and 1kg potassium hydroxide to react for 15h, adjust the pH value of the system to 5 with concentrated sulfuric acid, filter, wash, and dry to obtain carboxylated nano-graphene;

[0030] Dissolve 1 kg of β-cyclodextrin in 60 kg of 1.2 mol / L sodium hydroxide solution, add 1 kg of epichlorohydrin dropwise under stirring for 1 hour, wash and dry to obtain pretreated cyclodextrin;

[0031] Mix 20kg of carboxylated nano-graphene and 50kg of dichloroethane evenly, add 0.2kg of silane coupling agent and stir for 1h at a temperature o...

Embodiment 2

[0035] A preparation method for a composite material for polyurethane water-based paint, comprising the steps of:

[0036] S1. Ultrasonically disperse 12kg of nano-graphene oxide in 40kg of water. The particle size of nano-graphene oxide is 10-200nm, and the thickness of the sheet is 0.1-1nm. The ultrasonic power is 500W, and then 1kg of hydrazine hydrate is added. Reflux reaction for 20h, continue to add 3kg aminophenylacetic acid, 0.15kg isoamyl nitrite, 2kg potassium hydroxide to react for 5h, adjust the pH value of the system to 5.6 with concentrated sulfuric acid, filter, wash, and dry to obtain carboxylated nano-graphene;

[0037] Dissolve 4kg of β-cyclodextrin in 40kg of 1.6mol / L sodium hydroxide solution, add 0.4kg of epichlorohydrin dropwise under stirring for 2 hours, wash and dry to obtain pretreated cyclodextrin;

[0038]Mix 10kg of carboxylated nano-graphene and 70kg of dichloroethane evenly, add 0.1kg of silane coupling agent and stir for 2 hours, the stirring te...

Embodiment 3

[0042] A preparation method for a composite material for polyurethane water-based paint, comprising the steps of:

[0043] S1. Ultrasonically disperse 8kg of nano-graphene oxide in 55kg of water. The particle size of nano-graphene oxide is 10-200nm, and the thickness of the sheet is 0.1-1nm. The ultrasonic power is 430W, and then 2.5kg of hydrazine hydrate is added. ℃ reflux reaction for 28 hours, continue to add 1.5kg aminophenylacetic acid, 0.4kg isoamyl nitrite, 1.3kg potassium hydroxide to react for 12 hours, adjust the pH value of the system to 5 with concentrated sulfuric acid, filter, wash and dry to obtain carboxylated nano Graphene;

[0044] Dissolve 3kg of β-cyclodextrin in 45kg of sodium hydroxide solution with a concentration of 1.5mol / L, add dropwise 0.6kg of epichlorohydrin to react for 1.7h under stirring, wash and dry to obtain pretreated cyclodextrin;

[0045] Mix 13kg carboxylated nano-graphene and 65kg dichloroethane evenly, add 0.12kg silane coupling agent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com