Preparation method of flaky tungsten sulfide/tungsten phosphide/carbon catalytic material

A sheet-like structure, tungsten sulfide technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of poor conductivity, high energy consumption for preparation, low catalytic activity, etc., to reduce costs. , the synthesis process is simple, the effect of high electrochemical hydrogen evolution activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Weigh 4.8g bismuth nitrate dissolved in 10ml 20% nitric acid solution (as solution B), weigh 1.6g sodium tungstate dissolved in 40ml distilled water (as solution A), mix A solution and B solution evenly, use NaOH The pH value of the solution was adjusted to 7, washed and dried, and the product was placed in a muffle furnace for 5 o C / min heating up to 400 o C calcined for 4h. Weigh 4 g of the obtained product, acidify with 150 mL of 6M hydrochloric acid for 100 h, and dry in vacuo. Take 3g of the prepared material and 10.5g of dodecylamine, add 150ml of cyclohexane, react at room temperature for 72h, wash with absolute ethanol 3 times, and obtain the intercalation precursor material.

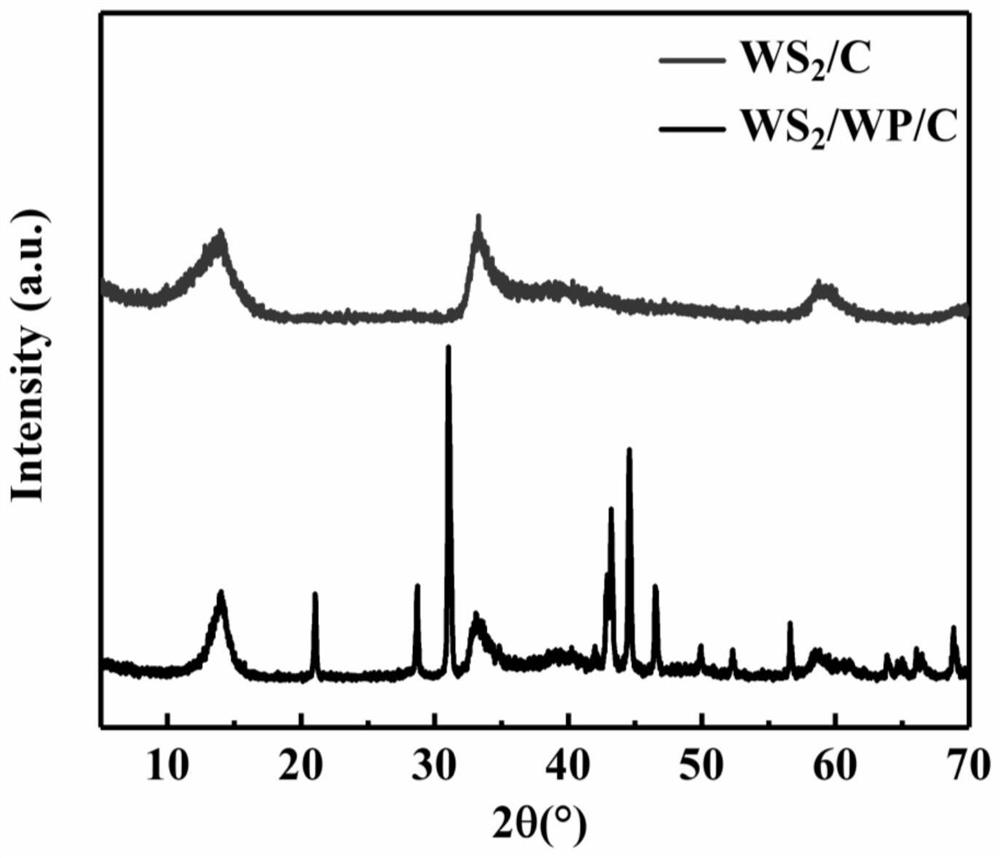

[0029] (2) Weigh 0.2g intercalation precursor material and 3.2g thiourea, mix the two materials evenly and put them into the corundum boat, put the corundum boat into the vacuum tube furnace, 2 Under the atmosphere, the temperature was raised to 750°C at 2°C / min and kept at a const...

Embodiment 2

[0032] (1) Weigh 5g bismuth oxide and dissolve in 7ml 30% nitric acid solution (as solution B), weigh 2g sodium tungstate and dissolve in 50ml distilled water (as solution A), mix A solution and B solution evenly and adjust the pH value to 7.5, after washing and drying, place in the muffle furnace for 3 o C / min heating up to 450 o C constant temperature 3h. Weigh 4g of the obtained product and acidify it with 180mL 5M hydrochloric acid solution for 100h. 3.5 g of the prepared material and 40 ml of ethylenediamine were dissolved in 150 ml of cyclohexane, reacted at room temperature for 72 h, washed 3 times with cyclohexane, and dried in vacuum to obtain an intercalation precursor material.

[0033] (2) Weigh 0.3g of the intercalation precursor material and 4.8g of thiourea, mix the two materials evenly and grind them into a corundum boat, put the corundum boat into a vacuum tube furnace, 2 Under the atmosphere, the temperature was raised to 700°C at 2°C / min and kept at a con...

Embodiment 3

[0036] (1) Weigh 4.85g bismuth nitrate and dissolve it in 10ml 20% nitric acid solution (as solution B), weigh 1.65g sodium tungstate and dissolve it in 40ml distilled water (as solution A), mix solution A and solution B and adjust the pH value to 8. The product was placed in a muffle furnace for 5 o C / min heating up to 500 o C, cooled to room temperature. Weigh 4g of the prepared material, acidify it with 100mL 10M hydrochloric acid for 72h, and dry it by suction filtration. 3 g of the prepared material and 150 ml of n-butylamine were dissolved in 100 ml of heptane, reacted at room temperature for 60 h, washed 3 times with heptane, and dried in vacuum to obtain an intercalation precursor material.

[0037] (2) Weigh 0.3g intercalation precursor material and 2.5g sulfur element, grind and mix the two materials evenly and place them in a corundum boat, put the corundum boat into a vacuum tube furnace, and 2 Under the atmosphere, the temperature was raised to 800°C at 3°C / mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com