Method for pulse electrodeposition of Ni-SiC composite coating on surface of aluminum alloy

A technology of pulse electrodeposition and aluminum alloy surface, applied in the direction of superimposed layer plating, metal material coating process, coating, etc. Uneven distribution and other problems, to achieve the effect of small porosity, strong binding ability and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

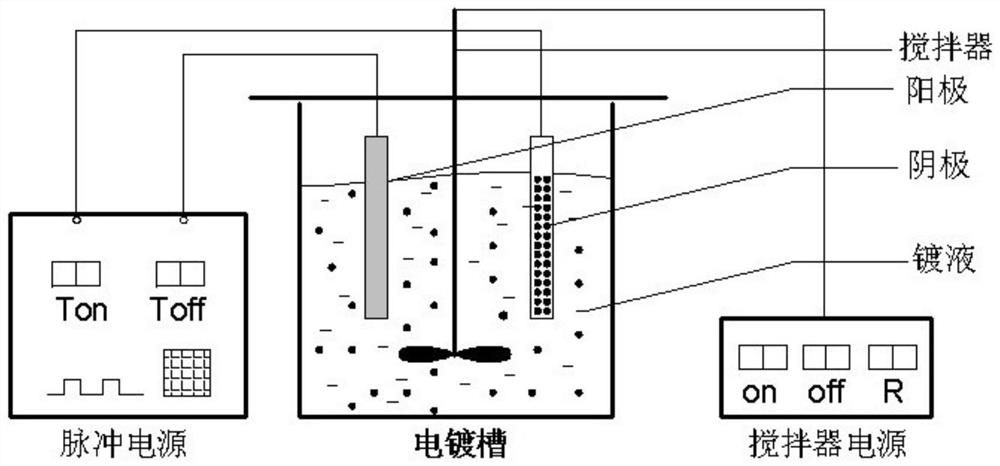

[0037] The preparation method of Ni-SiC micron composite coating sample 1 comprises the following steps:

[0038] (1) Preparation of electroplating solution: The composite plating solution is prepared according to the proportion of deionized water and drug powder, and the drug powder and deionized water are fully mixed by mechanical stirring; the duration of mechanical stirring is 3.5h, and the rotation speed 150r / min. The components of the Ni-SiC micro-composite coating bath are: sodium citrate: 110g / L, disodium edetate: 27g / L, nickel sulfate: 220g / L, nickel chloride: 28g / L, boric acid : 18g / L, silicon carbide micron powder with a particle size of 25μm: 50g / L, surfactant sodium stearate: 1.5g / L.

[0039](2) Mechanical leveling and pretreatment of aluminum alloy samples: firstly, use a wire cutting machine to cut the aluminum alloy blanks into flat surface and moderate-sized sheet structures, and then use 300#, 600#, 800#, 1000#, 1500# sandpaper for grinding, and then use em...

Embodiment 2

[0043] The preparation method of Ni-SiC nanocomposite coating sample 2 comprises the following steps:

[0044] (1) Preparation of electroplating solution: The composite plating solution is prepared according to the proportion of deionized water and drug powder, and the drug powder and deionized water are fully mixed by mechanical stirring; the duration of mechanical stirring is 3.5h, and the rotation speed 150r / min. The components of the Ni-SiC nanocomposite coating bath are: sodium citrate: 110g / L, disodium edetate: 27g / L, nickel sulfate: 220g / L, nickel chloride: 28g / L, boric acid : 18g / L, silicon carbide nanopowder with a particle size of 60nm: 50g / L, surfactant sodium stearate: 1.5g / L.

[0045] (2) Mechanical leveling and pretreatment of the aluminum alloy sample: use a wire cutting machine to cut the aluminum alloy blank into a sheet structure with a flat surface and a moderate size. The aluminum alloy samples were polished with 300#, 600#, 800#, 1000#, and 1500# sandpap...

experiment example 3

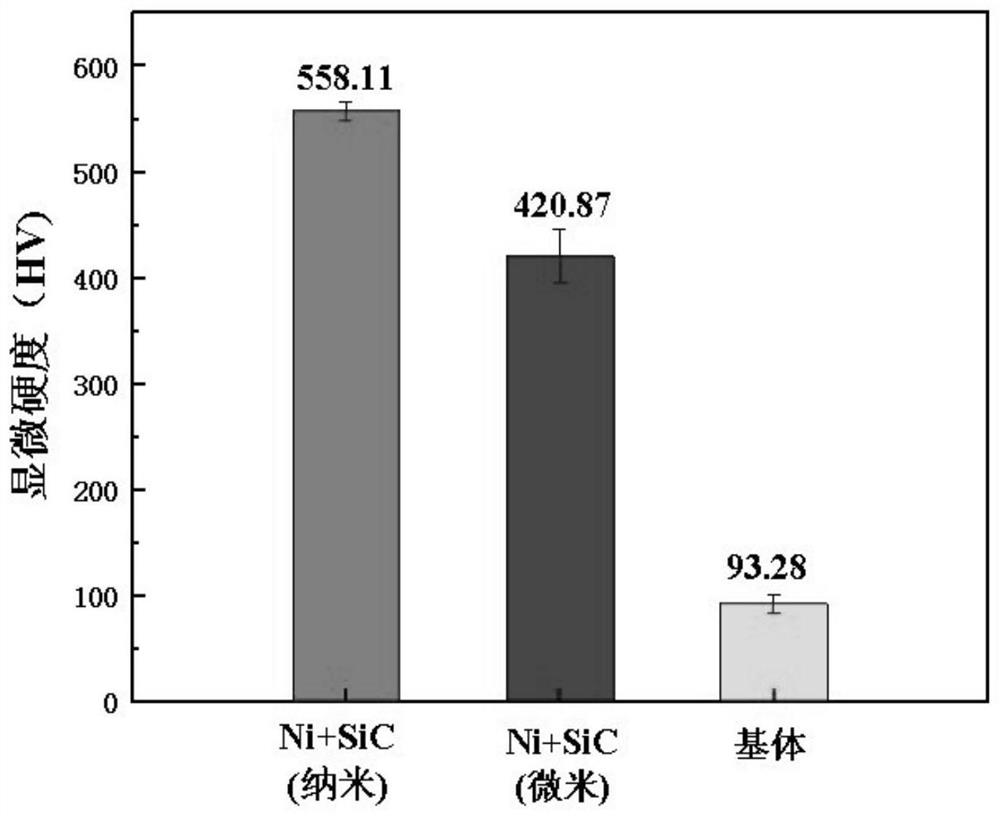

[0049] The structure and properties of the prepared coating were determined by using SEM, microhardness test, and corrosion resistance test. The experimental results showed that under the condition of mechanical stirring, the Ni-SiC composite coating prepared by pulse power supply had high density, SiC The particles are evenly distributed, with high hardness and excellent wear resistance and wear resistance.

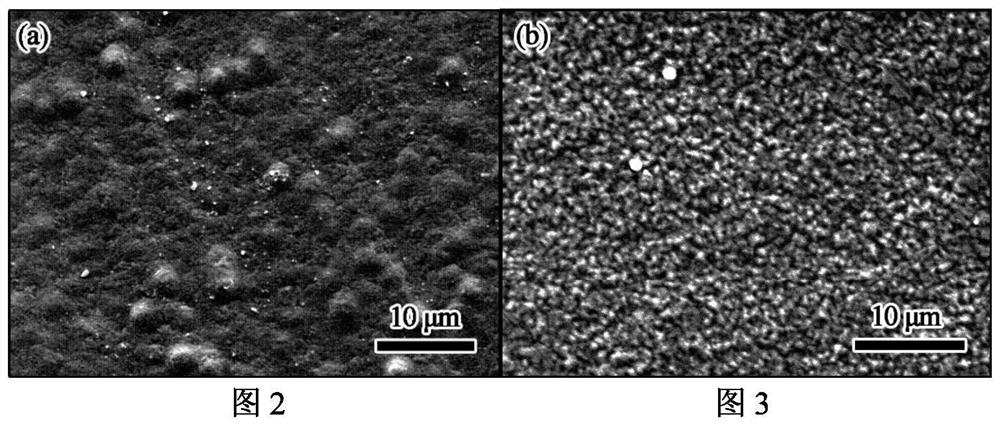

[0050] (1) Surface morphology of Ni-SiC composite coating:

[0051] The surface morphology of the coating was observed with a Phenom XL desktop scanning electron microscope, such as figure 2 , image 3 Shown: in the Ni-SiC micro-composite coating that uses pulse composite electrodeposition technology to prepare in the present invention, SiC particle distributes evenly, does not have obvious cluster phenomenon to produce; In the Ni-SiC nano-composite coating prepared, the grain The degree is finer, and the morphology becomes more uniform and dense. It is also easy to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com