A kind of water-absorbent resin and preparation method thereof

A water-absorbent and resin technology, applied in the field of water-absorbent resin and its preparation, can solve the problems of insufficient water-holding capacity, inability to obtain a comprehensive performance-balanced water-absorbent resin, and lack of liquid-passing properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

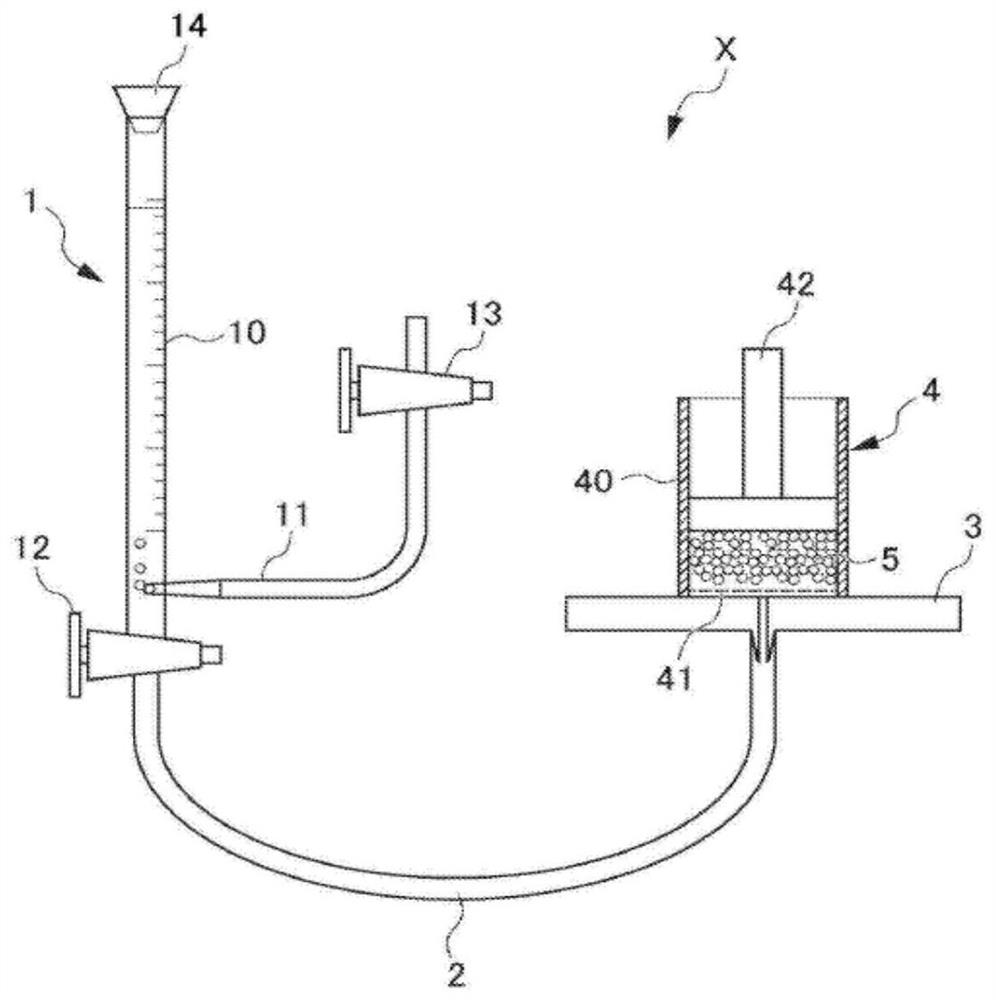

[0064] Preparation of Aqueous Epoxy Dispersion A (Step-by-Step Process):

[0065] Inject 800g of PEG6000 after melting and dehydration into the kettle, keep the temperature in the kettle at 80 ° C, then add 47 g of hexahydrophthalic anhydride into the reaction kettle, heat up to 100 ° C, react for about 3h, and sample and test the acid value to reach the theoretical value of 10mgKOH / g (by NaOH back titration measurement, the same below), inject 210g of liquid epoxy resin E20, stir evenly, add 3.5g of triphenylphosphorus catalyst, and react at 130 ° C for 3h, the test acid value is -0.25mgKOH / g and then discharge, preparation An active emulsifier is obtained. Inject 450g of molten epoxy resin E20 into the dispersion kettle, maintain the temperature in the kettle at 100°C, then add 100g of the active emulsifier prepared above and 100g of ethylene glycol dimethyl ether solvent, stir and mix at 800r / min for 20min; then cool down to 75 ℃, the lifting speed is 1200r / min, 400g of de...

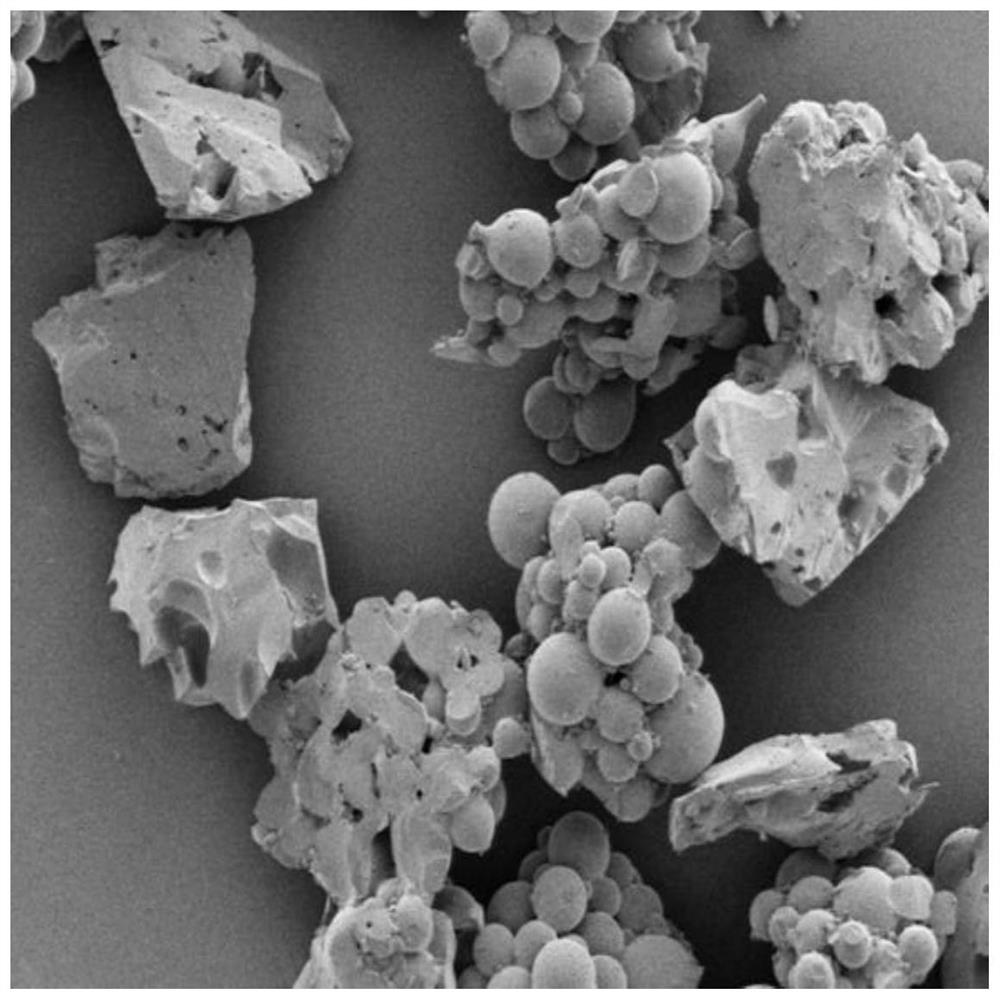

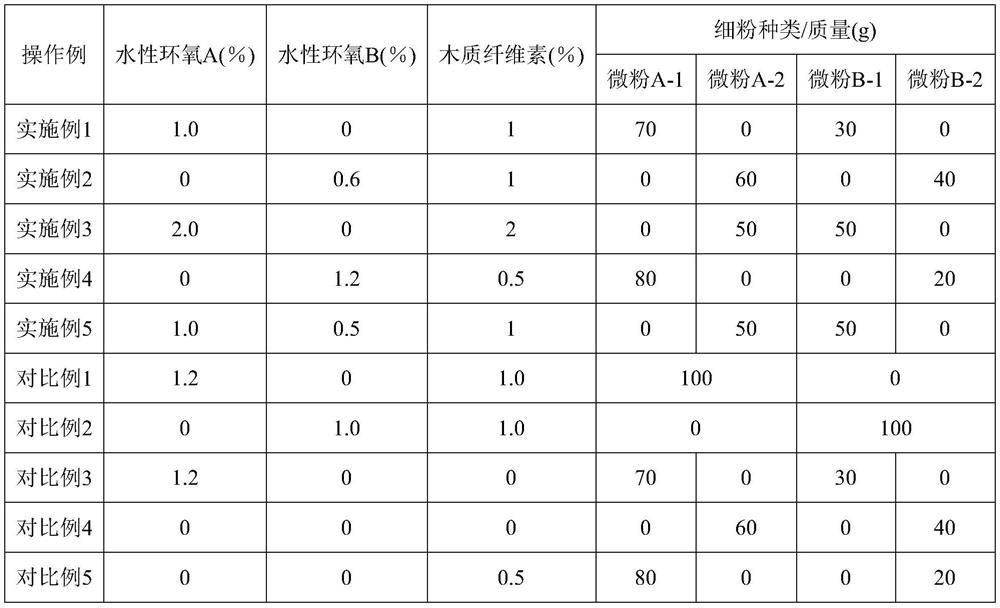

Embodiment 1

[0070] Take 70g of micropowder A-1 and 30g of micropowder B-1 prepared by the two processes and mix them with 1.0g of lignocellulose, add 100g of deionized water containing 1% 1,3-propanediol, and make them swell evenly and form a hydrogel. glue particles. The granulated hydrogel particles are dried at 210° C. to a moisture content of less than 3%. Then, the dried water-absorbent resin particles are ground and sieved to obtain the original powder with a particle size distribution of 150-850 microns. Finally, water-based epoxy dispersion A, which accounts for 1.0% of the total mass of the two micro-powders, is evenly sprayed into the obtained raw powder to make it evenly dispersed and adsorbed, and dried at 130 °C for 1 hour to obtain finished products with special morphology and performance. .

Embodiment 2

[0072] Take 60g of micropowder A-2 and 40g of micropowder B-2 prepared by the two processes and mix them with 1.0g of lignocellulose, add 100g of deionized water containing 2% 1,4-butanediol to make them swell evenly and form Hydrogel particles. The granulated hydrogel particles are dried at 210° C. to a moisture content of less than 3%. Then, the dried water-absorbent resin particles are ground and sieved to obtain the original powder with a particle size distribution of 150-850 microns. Finally, water-based epoxy dispersion B, which accounts for 0.6% of the total mass of the two micro-powders, is evenly sprayed into the obtained raw powder to make it evenly dispersed and adsorbed, and dried at 130 °C for 1 hour to obtain finished products with special morphology and performance. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com