Compound fertilizer containing biomass charcoal, and preparation method thereof

A technology of biomass charcoal and compound fertilizer, applied in chemical instruments and methods, fertilization devices, carbon compounds, etc., can solve the problem of single efficacy, achieve high degree of aroma, delay initial concentration, and reduce supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

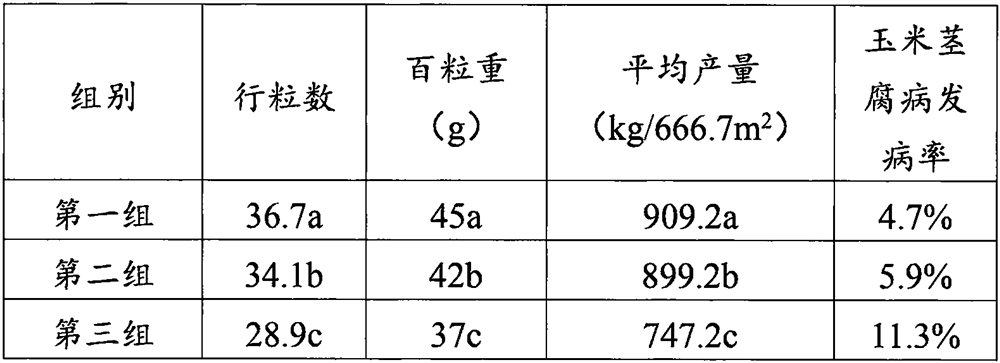

Examples

preparation example Construction

[0049] In the present invention, the preparation method of described biochar comprises the following steps:

[0050] (1) mixing corn stalks and fruit branches according to a mass ratio of 1-4: 1-2 to obtain a mixture of straw and fruit branches;

[0051] (2) mixing the straw fruit branch mixture with an aqueous potassium carbonate solution, drying after soaking to obtain an activated straw mixture;

[0052] The mass ratio of the straw fruit branch mixture to the potassium carbonate aqueous solution is 1: 2 to 4;

[0053] (3) Heating the activated straw and fruit branch mixture to 380-420°C and keeping it for 45-60 minutes; then raising the temperature to 580-620°C and keeping it for 60-100 minutes to obtain the carbonized material;

[0054] (4) After cooling, the carbonized material is soaked in hydrochloric acid solution, taken out, washed with water until neutral, and dried to obtain biochar.

[0055] In the present invention, the fruit branches refer to discarded branches...

Embodiment 1

[0086] Example 1 Compound fertilizer containing biochar

[0087] 1. Preparation of biochar

[0088] The discarded corn stalks and fruit branches are collected, crushed to 40 meshes respectively, and mixed according to the mass ratio of 2:3 to obtain a mixture of straw and fruit branches. Potassium carbonate is taken according to the ratio of 1:3 of the mass ratio of straw fruit branch mixture and potassium carbonate, and water is added to make potassium carbonate solution with a concentration of 1mol / L, and the above straw fruit branch mixture is mixed with the obtained potassium carbonate solution, 32 After impregnating at ℃ for 6 hours, drying at 80 ℃ to obtain the activated straw mixture.

[0089] Put the activated straw mixture in a muffle furnace, first raise the temperature to 400°C at a rate of 6°C / min, and keep it for 50 minutes; then continue to raise the temperature to 600°C at a rate of 10°C / min, and keep it for 80 minutes to obtain a carbonized material. After th...

Embodiment 2

[0095] Example 2 Compound fertilizer containing biochar

[0096] 1. Preparation of biochar

[0097] The discarded corn stalks and fruit branches are collected, crushed to 60 mesh respectively, and mixed according to a mass ratio of 1:1 to obtain a mixture of straw and fruit branches. Take potassium carbonate according to the mass ratio of straw fruit branch mixture and potassium carbonate 1:2, add water and potassium carbonate is mixed with a concentration of potassium carbonate solution that is 5mol / L, and mix the above straw fruit branch mixture with the obtained potassium carbonate solution for 30 After soaking at ℃ for 5 hours, drying at 75 ℃ to obtain the activated straw fruit branch mixture.

[0098] Put the activated straw and fruit branch mixture in a muffle furnace, first raise the temperature to 420°C at a rate of 5°C / min, and keep it for 40 minutes; then continue to raise the temperature to 580°C at a rate of 12°C / min, and keep it for 100 minutes to obtain a charre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com