High-frequency and low-loss flexible insulating adhesive film material, and preparation method and application thereof

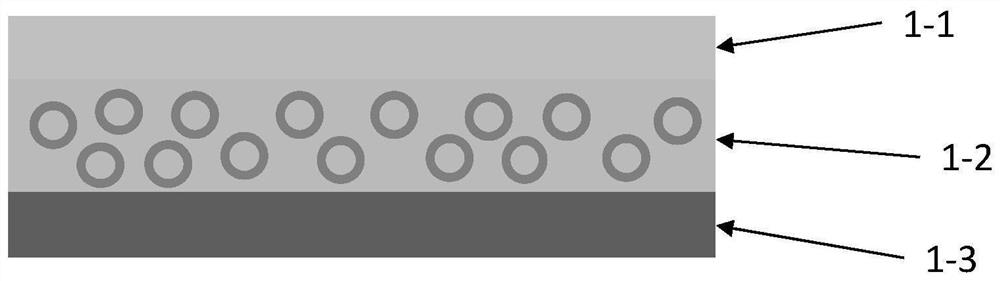

A technology of insulating adhesive film and dielectric materials, applied in the direction of dielectric materials, circuit substrate materials, adhesives, etc., can solve the problems of reducing the bonding force between dielectric materials and copper foil, reducing the heat resistance and processability of dielectric materials, and achieving The effect of low dielectric loss, simple preparation method, and low dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] 1. Add 0.4g of sodium bicarbonate, 0.08g of fatty alcohol polyoxyethylene ether, and 2.5g of vinyltrimethoxysilane into 250ml of deionized water in turn, mix and stir for 180min at a stirring speed of 300rpm; add 0.06g of ethyl orthosilicate Add the reaction system, stir and react for 180min, the stirring rate is 300rpm, and discharge; after the prepared hollow silica is dried at 50°C, it is heat-treated at 300°C for 2 hours to obtain a hollow silica with a particle size of 380nm and a wall thickness of 50nm. Silicon oxide;

[0051] 2. Dissolve 5g of epoxy resin CYD-127E, 10g of NPCN-701, and 15g of YX4000 in 30g of butanone to obtain an epoxy resin solution;

[0052] 3. Add 30g of hollow silica prepared above, 2.4g of OMICURE DDA 5, 10g of N,N-dimethylformamide, and the epoxy resin solution prepared above into a stirrer, and stir at a speed of 300rpm for 12 hours to obtain electronic paste;

[0053] 4. Use a slit coater to coat the electronic paste on the surface of ...

Embodiment 2

[0056] 1. Add 0.4g of sodium bicarbonate, 0.08g of fatty alcohol polyoxyethylene ether, and 2.5g of vinyltrimethoxysilane into 250ml of deionized water in turn, mix and stir for 180min at a stirring speed of 300rpm; add 0.06g of ethyl orthosilicate Add the reaction system, stir and react for 180min, the stirring rate is 300rpm, and discharge; after the prepared hollow silica is dried at 50°C, it is heat-treated at 300°C for 2 hours to obtain a hollow silica with a particle size of 380nm and a wall thickness of 50nm. Silicon oxide;

[0057] 2. Dissolve epoxy resin NPES-909 5g, NPCN-701 10g, YX4000 10g, CYDB-700 5g in 30g butanone to obtain epoxy resin solution;

[0058] 3. Add 20g of the hollow silica prepared above, 2g of OMICURE U-415, 0.02g of OMICURE 24EMI, 10g of N,N-dimethylformamide, and the above-mentioned epoxy resin solution into the stirrer, at 300rpm Stir at a rotating speed for 12 hours to obtain an electronic slurry;

[0059] 4. Use a slit coater to coat the ele...

Embodiment 3

[0062] 1. Preparation of carbon spheres with a diameter of 500 nm. Take 80ml of the prepared glucose solution with a concentration of 1mol / L and add it to a polytetrafluoroethylene-lined reaction kettle, then put the reaction kettle into an oven at 175°C for 10 hours, then cool to room temperature naturally, and filter the product to obtain brown-black charcoal balls. Brown-black carbon spheres were alternately washed three times with absolute ethanol and deionized water, and dried at 60°C for later use.

[0063] 2. Add 10mmol of aluminum chloride to a mixture of 120ml of deionized water and 40ml of absolute ethanol, add 1g of the carbon spheres prepared above, stir for 30min, add 0.1mol of urea, and stir in a 60°C water bath for 24h. Then, the brown-black solid was obtained by suction filtration, and washed three times with deionized water and absolute ethanol to remove residual anions and cations, and the washed samples were dried in an oven at 60°C. Finally, the dried sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com