Hydrophilic hot-melt adhesive, preparation method and application thereof

A hot-melt, hydrophilic technology, used in adhesives, polyurea/polyurethane adhesives, adhesive types, etc., can solve the problems of reducing the surface tension of urine, increasing urine leakage, etc., to improve the absorption performance, Improve the effect of absorption, preparation method and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] As an aspect of the technical solution of the present invention, it relates to a method for preparing a hydrophilic hot-melt adhesive, which includes: making polyols containing polyhydroxy polyethers, polyhydroxy polyesters, polyhydric alcohols that may or may not be contained, The homogeneous mixed reaction system copolymerization reaction of polyisocyanate, low-melting point polyester with or without inclusion, and polyurethane with or without inclusion forms a hydrophilic hot-melt adhesive.

[0026] In some embodiments, the above polyhydroxy polyether and polyhydroxy polyester can be pre-mixed and stirred by heating, and then polyisocyanate can be added in one or more steps. The temperature of the copolymerization reaction is 60-160° C., and the time is 1-8 hours, preferably 2-8 hours.

[0027] Further, after the reaction is completed, materials such as polyhydroxy polyethers, polyhydroxy polyesters, polyols, polyurethanes, and low-melting point polyesters can be fur...

Embodiment 1

[0055] In this embodiment, the formula of the hydrophilic hot-melt adhesive is selected as 25 g of difunctional polyethylene adipate (molecular weight 3000), 40 g of difunctional polyethylene glycol (molecular weight 3000), and polyneopentyl adipate. Alcohol (molecular weight: 3000) 25g, trifunctional polyether 16g, MDI 9.5g. The above components were uniformly mixed and then copolymerized. The reaction temperature was set at 160° C. and the reaction time was 1 h. After that, 6 g of neopentyl glycol was added, and the temperature was gradually lowered to 120° C. for 1 hour.

[0056] The hydrophilic hot-melt adhesive synthesized in this example has a viscosity of 7000 centipoise at 160° C. and can be effectively coated on a non-woven fabric substrate.

Embodiment 2

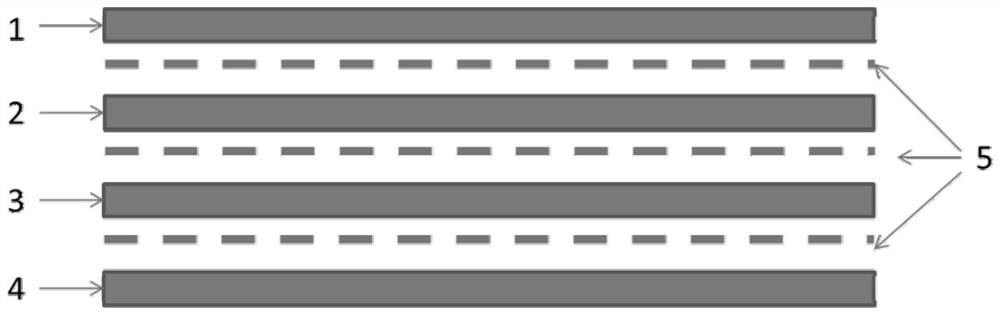

[0058] The hydrophilic hot-melt adhesive prepared in Example 1 was compared with the commercially available rubber-based hot-melt adhesive, using sizing coating equipment, using 15g / m 2 Two pieces of hydrophilic spun-bonded non-woven fabrics are used, and the surface of the first non-woven fabric is coated with linear glue lines with a diameter of 0.5mm, and the distance between the glue lines is 3mm, and then the second piece of non-woven fabric is pasted. Use a dust-free filter paper pad to test the permeation rate of physiological saline under the above non-woven layer to be tested. Use 1cm 2 Use a syringe with a cross-sectional area, use 5mL of normal saline each time, and record the penetration time of the first, second and third times of normal saline respectively. The results are shown in Table 1 below.

[0059] Table 1

[0060] Seepage time (s) Hydrophilic hot melt adhesive structure Rubber-based adhesive construction the first time 24 24 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com