Polycrystalline ternary positive electrode material as well as preparation method and application thereof

A cathode material and element technology, applied in the field of polycrystalline ternary cathode materials and their preparation, to achieve the effects of improving cycle performance, slowing down cracking, and good structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

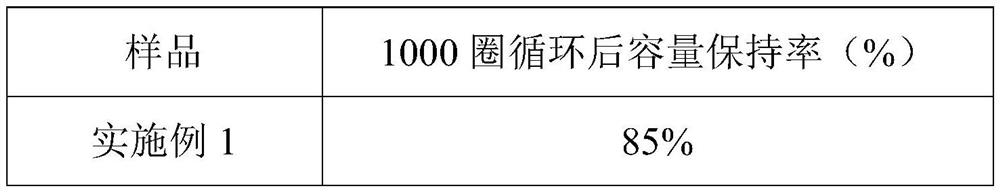

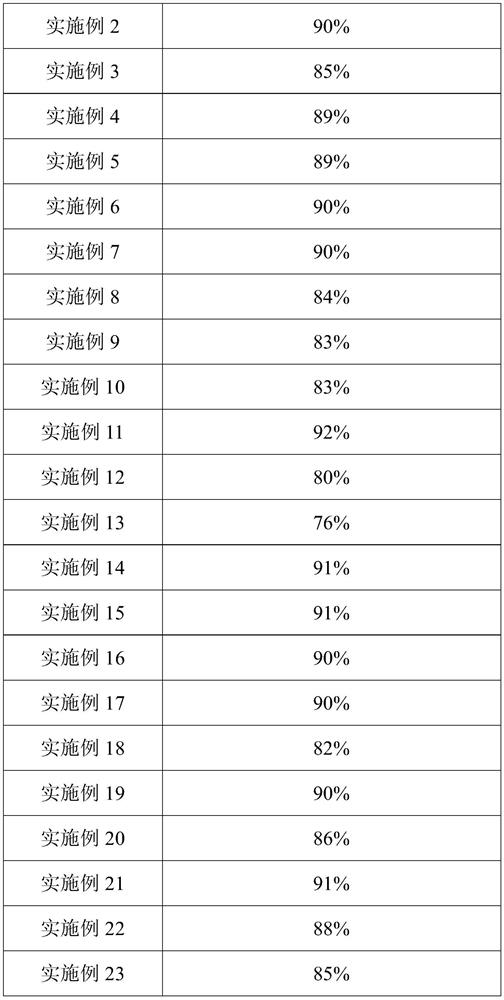

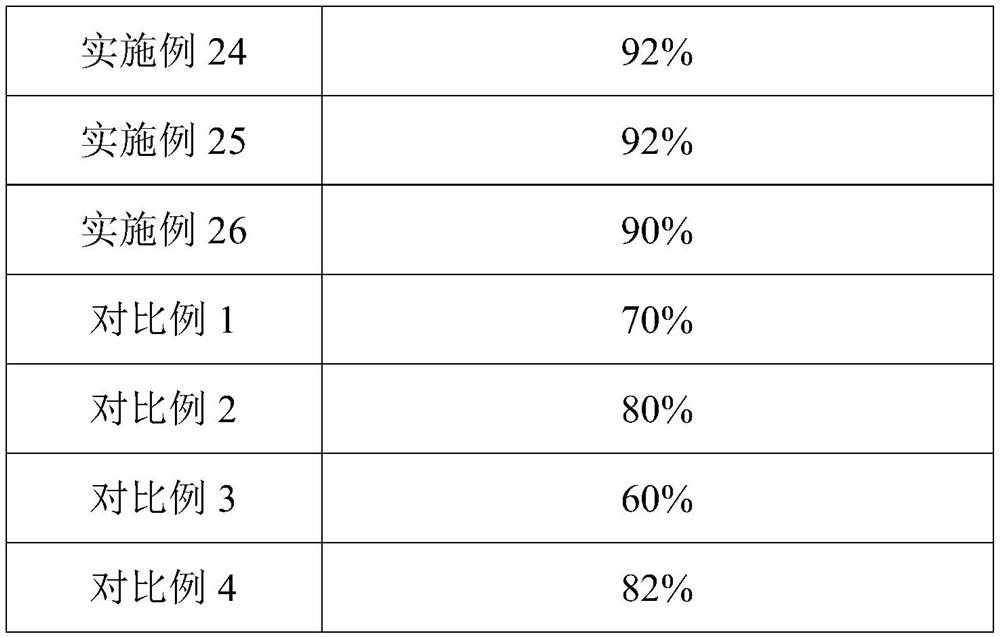

Examples

Embodiment 1

[0079] This embodiment provides a method for preparing a polycrystalline ternary cathode material, the method comprising the following steps:

[0080] (1) According to the mass ratio of 0.05:100, the H 3 BO 3 and Ni 0.83 co 0.12 mn 0.05 (OH) 2 Mix and heat up to 150°C at a rate of 1°C / min in nitrogen, and sinter for 48 hours to obtain a polycrystalline ternary cathode material precursor;

[0081] (2) Mix the polycrystalline ternary cathode material precursor obtained in step (1) with lithium hydroxide, raise the temperature to 700° C. at a rate of 1° C. / min, and sinter for 48 hours to obtain the polycrystalline ternary cathode material;

[0082] The molar ratio of the lithium element in the lithium hydroxide to the molar sum of the nickel element, cobalt element and manganese element in the nickel-cobalt-manganese hydroxide is controlled to be 1.01:100.

[0083] In the polycrystalline ternary positive electrode material obtained in this embodiment, the particle size of t...

Embodiment 2

[0085] This embodiment provides a method for preparing a polycrystalline ternary cathode material, the method comprising the following steps:

[0086] (1) According to the mass ratio of 0.3:100, the B 2 o 3 and Ni 0.83 co 0.12 mn 0.05 (OH) 2 Mix and heat up to 380°C at a rate of 5°C / min in argon, and sinter for 30 hours to obtain a polycrystalline ternary cathode material precursor;

[0087] (2) Mix the polycrystalline ternary cathode material precursor obtained in step (1) with lithium hydroxide and alumina, heat up to 800°C at a rate of 5°C / min, and sinter for 26 hours to obtain the polycrystalline ternary cathode material ;

[0088] Controlling the ratio of the mole of lithium element in the lithium hydroxide to the molar sum of nickel element, cobalt element and manganese element in the nickel-cobalt-manganese hydroxide is 1.04:100, and the mass ratio of aluminum element to polycrystalline ternary positive electrode material is 0.25: 100.

[0089]The polycrystallin...

Embodiment 3

[0091] This embodiment provides a method for preparing a polycrystalline ternary cathode material, the method comprising the following steps:

[0092] (1) According to the mass ratio of 0.5:100, the (C 3 h 7 O) 3 B and Ni 0.83 co 0.12 mn 0.05 (OH) 2 Mix and heat up to 500°C at a rate of 10°C / min in argon, and sinter for 12 hours to obtain a polycrystalline ternary cathode material precursor;

[0093] (2) Mix the polycrystalline ternary cathode material precursor obtained in step (1) with lithium nitrate and titanium dioxide, heat up to 900°C at a rate of 10°C / min, and sinter for 4 hours to obtain the polycrystalline ternary cathode material;

[0094] Control the molar ratio of the lithium element in the lithium nitrate to the molar sum of the nickel element, cobalt element and aluminum element in the nickel-cobalt-manganese hydroxide to be 1.08:100, and the mass ratio of the titanium element to the polycrystalline ternary positive electrode material is 0.5:100 .

[009...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com