Phthalocyanine pigment color paste, and preparation method and application thereof

A technology for phthalocyanine pigments and color pastes, applied in the direction of pigment pastes, etc., can solve the problems that are difficult to meet the storage stability, moisture retention, and environmental protection performance requirements of the automatic coloring system of paints, and achieve good storage stability and moisture retention, Enhance the effect of dispersion and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

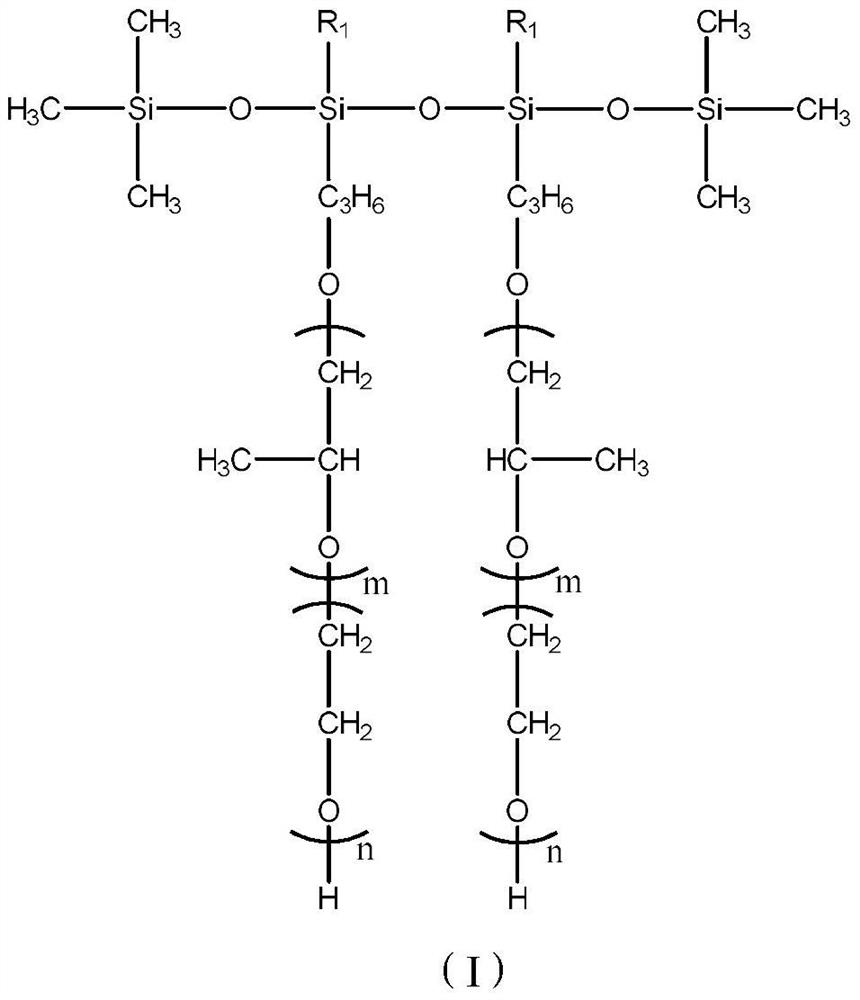

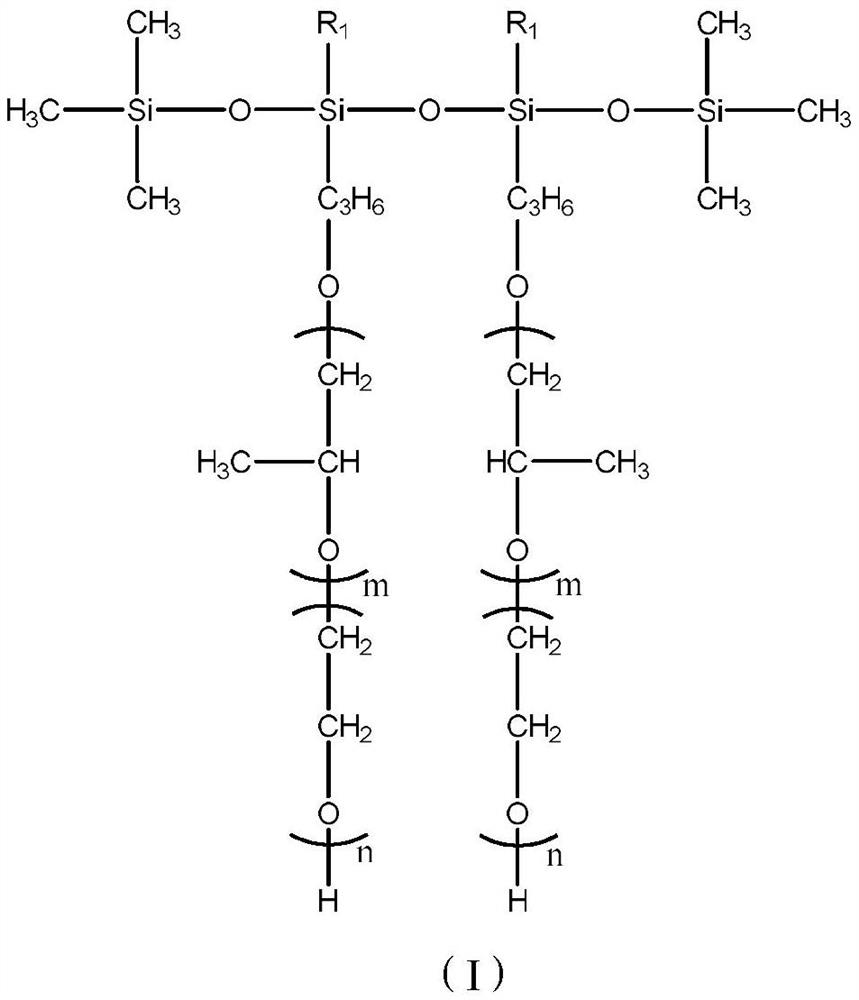

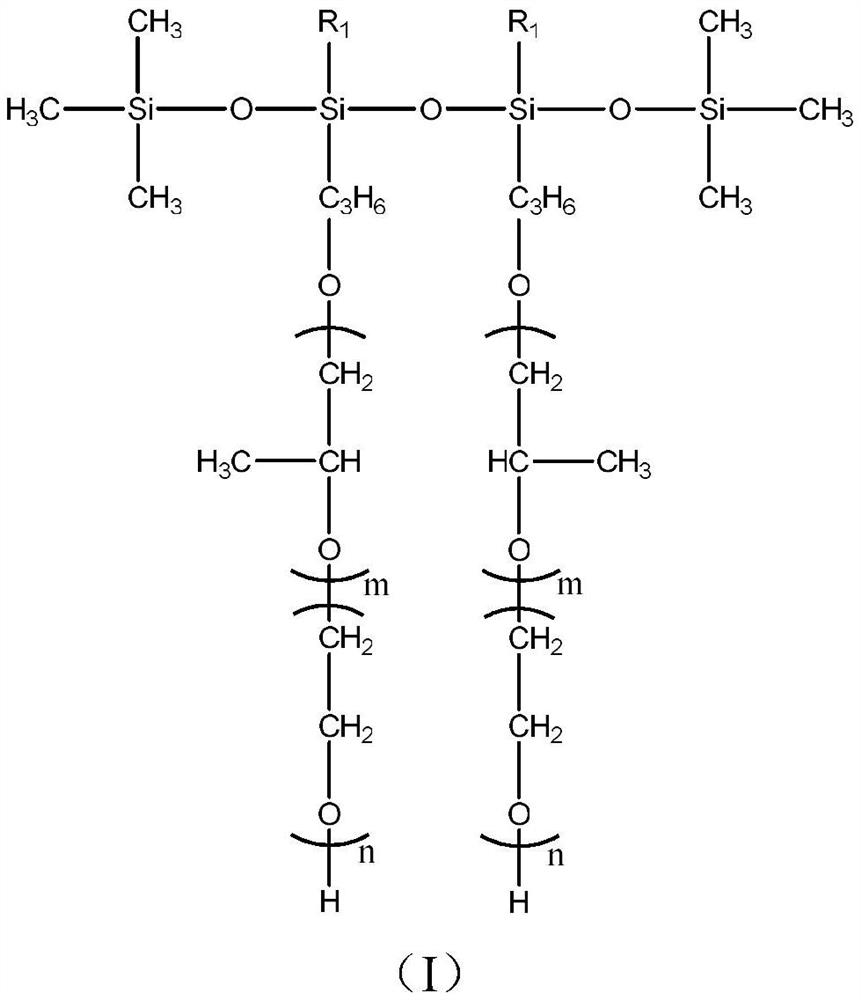

Method used

Image

Examples

Embodiment 1

[0031] The surface modified phthalocyanine pigment is prepared by the following steps:

[0032] S1: Add 1 part by mass of phthalocyanine blue 15:3 pigment to 6 parts by mass of chlorosulfonic acid and 2.5 parts by mass of concentrated sulfuric acid under stirring conditions, and stir for 45 minutes; add 0.8 parts by mass of chlorosulfuric acid Sulfoxide, slowly warming up to 90°C, reacting for 6 hours, cooling down, filtering, washing, and drying to obtain sulfonylated phthalocyanine blue 15:3 pigment;

[0033] S2: Add the sulfonylated phthalocyanine blue 15:3 pigment prepared in step S1 to 8 parts of water by mass, use sodium hydroxide pH adjuster to control the pH value to 9.0, and add 0.8 parts of ethylene glycol Amine, keep the temperature at 120°C, react for 7h, cool down, filter, wash, and dry to obtain the phthalocyanine blue 15:3 pigment of aminolysis;

[0034] S3: Add chloroacetic acid with a mass of 0.8 to 10 parts of absolute ethanol for dissolution, use a sodium h...

Embodiment 2

[0036] The surface modified phthalocyanine pigment is prepared by the following steps:

[0037] S1: Add 1 part by mass of phthalocyanine green pigment to 5 parts by mass of chlorosulfonic acid and 2 parts by mass of concentrated sulfuric acid under stirring conditions, and stir for 30 minutes; add 0.5 part by mass of thionyl chloride, Slowly raise the temperature to 120°C, react for 4 hours, cool down, filter, wash, and dry to obtain sulfonylated phthalocyanine green pigment;

[0038]S2: Add the sulfonylated phthalocyanine green pigment prepared in step S1 to 5 parts of water by mass, control the pH value to 7.0 with a potassium hydroxide pH regulator, and add 0.5 parts of dimethyl propane Amine, keep the temperature at 150°C, react for 4 hours, cool down, filter, wash, and dry to obtain the phthalocyanine green pigment of aminolysis;

[0039] S3: Add 0.5 parts of 3-chloropropionic acid to 10 parts of absolute ethanol for dissolving, control the pH value to 7.0 with potassium...

Embodiment 3

[0041] The surface modified phthalocyanine pigment is prepared by the following steps:

[0042] S1: Add 1 part by mass of phthalocyanine blue 15:1 pigment to 7 parts by mass of chlorosulfonic acid and 3 parts by mass of concentrated sulfuric acid under stirring conditions, and stir for 60 minutes; add 1 part by mass of chlorinated Sulfoxide, slowly warming up to 70°C, reacting for 8 hours, cooling down, filtering, washing, and drying to obtain sulfonylated phthalocyanine blue 15:1 pigment;

[0043] S2: The sulfonylated phthalocyanine blue 15:1 pigment prepared in step S1 is added to 10 parts of water by mass, and the pH value is controlled by a sodium bicarbonate pH regulator to 10.0, and 1 part by mass of 1, 4-Butanediamine, keep the temperature at 90°C, react for 10 hours, cool down, filter, wash, and dry to obtain the phthalocyanine blue 15:1 pigment of aminolysis;

[0044] S3: 1 part of 4-chlorobutyric acid is dissolved in 10 parts of absolute ethanol, and the pH value is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com