Anaerobic immobilized bacterial preparation, as well as preparation method and application thereof

An anaerobic digestion and bacterial agent technology, applied in biochemical equipment and methods, immobilized enzymes, immobilized on/in organic carriers, etc., can solve the weakening effect, intolerance to high ammonia concentration, enzyme agents It can restore functional activity, relieve toxic effects, and maintain structural integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

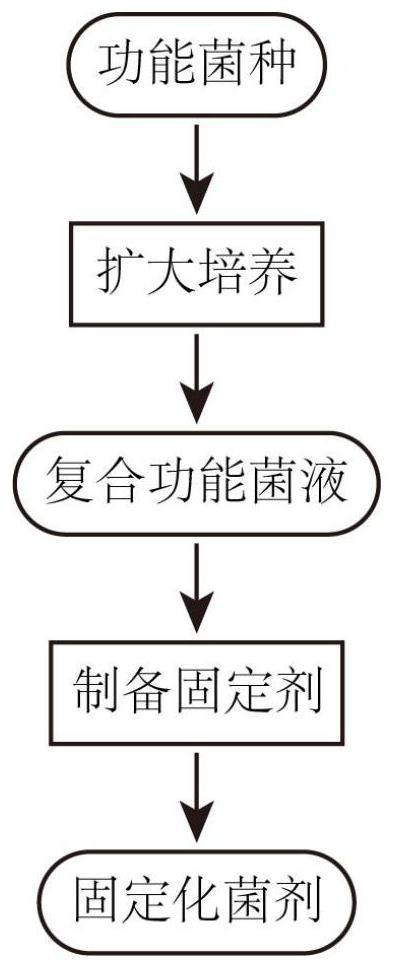

[0032] figure 1 It is the preparation flowchart of the anaerobic immobilized bacterial agent of the present invention, as figure 1 Shown, the preparation method of anaerobic immobilized bacterial agent is as follows:

[0033] Step 1: Perform anaerobic culture on four different anaerobic functional strains at a certain temperature to obtain corresponding culture liquids, and mix different culture liquids according to a certain volume ratio to obtain a composite functional bacterial liquid.

[0034] Step 2, centrifuging and concentrating the composite functional bacterial liquid to obtain functional bacterial flora precipitation.

[0035] Step 3, dissolve the functional flora precipitate in the polyvinyl alcohol aqueous solution to obtain the functional flora polyvinyl alcohol solution, then drop the functional flora polyvinyl alcohol solution into the first buffer solution, and let it stand for 24 hours to obtain the polyvinyl alcohol gel glue beads.

[0036] Step 4, put the...

Embodiment 1

[0063] This example specifically elaborates the preparation and application of the anaerobic immobilized bacterial agent.

[0064] Under the condition of 55 ℃, different anaerobic functional strains were cultivated by pure culture technology, and the OD600 of the culture liquid was 15. Take 180mL, 240mL, 120mL and 240mL of culture liquids of Faecalibacterium proteolyticus, Thermoacetogens brown, Methanosarcina pasteurii and Methanosarcina thermoautotrophicus, mix them, and concentrate them by centrifugation at a centrifugal force of 5000g , the centrifugation temperature was 4°C, and the centrifugation time was 5 minutes to obtain functional flora precipitates.

[0065] Add this functional flora precipitation to 50mL mass fraction and stir in the polyvinyl alcohol aqueous solution of 15%, obtain the functional flora polyvinyl alcohol solution, then drop this functional flora polyvinyl alcohol solution into every liter containing Na 2 HPO 4 , 0.15mol; NaH 2 PO 4 , 0.2mol; H...

Embodiment 2

[0070] This example specifically elaborates the preparation and application of the anaerobic immobilized bacterial agent.

[0071] Under the condition of 55 ℃, different anaerobic functional strains were cultivated by pure culture technology, and the OD600 of the culture liquid was 18. Take 150mL, 150mL, 200mL and 250mL culture liquids of Faecalibacterium proteolyticus, Thermoacetogens browna, Methanosarcina pasteurii and Methanosarcina thermoautotrophicus and mix them, then centrifuge and concentrate, centrifugal force 5000g , the centrifugation temperature was 4°C, and the centrifugation time was 5 minutes to obtain functional flora precipitates.

[0072] Add this functional flora precipitation to 60mL mass fraction and stir in 12% polyvinyl alcohol aqueous solution, drop the stirred polyvinyl alcohol aqueous solution into every liter containing Na 2 HPO 4 , 0.2mol; NaH 2 PO 4 , 0.23mol; H 3 BO 3 , 55g of the first buffer solution, let it stand for 24h to form polyviny...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com