Hippophae rhamnoides polysaccharide, preparation method and application of hippophae rhamnoides polysaccharide in hippophae rhamnoides dry paste

A technology of seabuckthorn polysaccharides and seabuckthorn, which is applied in the direction of pharmaceutical formulations, medical preparations containing active ingredients, plant raw materials, etc., can solve the problem of drug stability and effectiveness that need to be improved, unfavorable storage and transportation of drug dosage control, and easy breeding of microorganisms and other issues, to achieve the effect of improving physiological activity and anti-fatigue effect, preventing and eliminating sports fatigue, and increasing product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] A preparation method of seabuckthorn polysaccharide, comprising:

[0061] Carry out degreasing process to above-mentioned seabuckthorn;

[0062] Carrying out polysaccharide extraction on the seabuckthorn after the above-mentioned degreasing treatment, and the above-mentioned extraction is extracted by ultrasonic combined with enzymatic method;

[0063] Carrying out deproteinization treatment on the extract obtained by extraction, the Sevage reagent for the above deproteinization is n-butanol and trichloroacetic acid; the above deproteinization treatment is carried out under the intervention of 3-hydroxyhexanoic acid and 1,3-dihydroxyacetone; and,

[0064] Alcohol precipitation and drying are carried out on the extract obtained in the deproteinization treatment step to obtain seabuckthorn polysaccharide;

[0065] The above seabuckthorn polysaccharide is a water-soluble polysaccharide. The preparation method uses ultrasound combined with enzyme method to extract seabuck...

Embodiment 1

[0104] A preparation method of seabuckthorn polysaccharide, comprising the following steps:

[0105] (1) Wash the seabuckthorn medicinal material, crush it to pass through a 200-mesh sieve, then add 5 times the weight of petroleum ether for stirring and degreasing, the degreasing time is 8 hours, the temperature is 55°C, and then the petroleum ether is recovered by suction filtration, and then the filter residue is washed with water 3 times, suction filtration, collecting the filter residue for later use;

[0106] (2) Add 25 times the amount of distilled water to the degreased filter residue, and use ultrasound combined with enzymatic method to extract polysaccharides. The specific operating conditions are: the enzymes used in the enzymatic method are papain, pectinase, and cellulase, and the amount of enzyme added is 2.3%, the temperature is 45°C, the pH is 6.0, the ultrasonic power is 150W, and the ultrasonic auxiliary time is 20min. After the ultrasonication is completed, t...

Embodiment 2

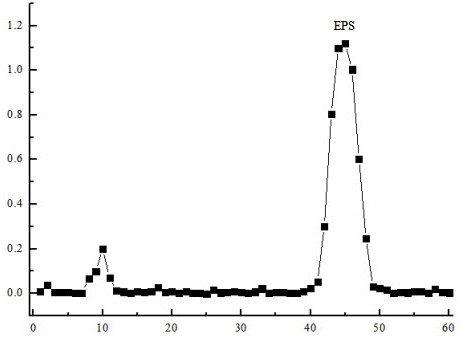

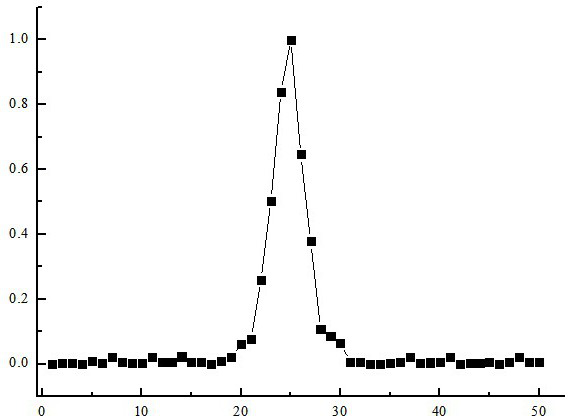

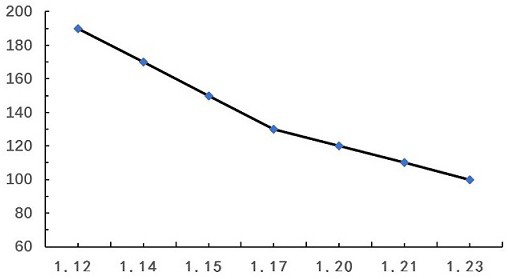

[0118] A kind of seabuckthorn dry paste, wherein the preparation process of extract and dry paste is as follows Figure 4 and 5 As shown, the specific preparation steps in this embodiment are as follows:

[0119] (1) After cleaning and slicing 15kg of seabuckthorn herbs, add 105L of water to a 500L sandwich pot for the first decoction. The decoction temperature is 190°C and the decoction time is 100min. Stir once every 20min. After decocting, filter through a 100-mesh sieve to obtain medicinal residue I and medicinal liquid I;

[0120] (2) Add 30L of water to the medicine dregs I, and decoct for the second time. The decoction temperature is 190°C, and the decoction time is 90 minutes. Stir once every 20 minutes. ;

[0121] (3) Add 15L of water to the medicine dregs II, and decoct for the third time. The decoction temperature is 190°C, and the decoction time is 30 minutes. Stir every 20 minutes. , discard the dregs III;

[0122] (4) Mixing medicinal liquid I, medicinal liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com