Hexagonal prism-shaped titanium niobate negative electrode material and preparation method thereof

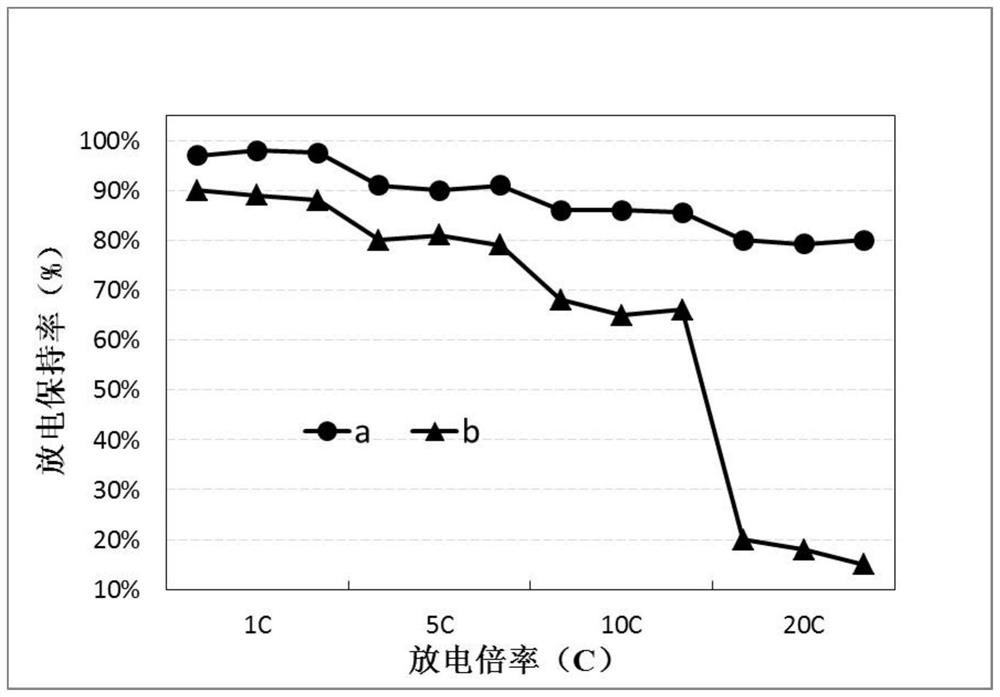

A negative electrode material, titanium niobate technology, applied in chemical instruments and methods, niobium compounds, battery electrodes, etc., can solve the problems of loss of material performance improvement effect, loss of core-shell structure characteristics, high cost of preparation process, etc., to improve electronic Effects of conductivity and ion diffusion rate, enhanced rate performance, and high power performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

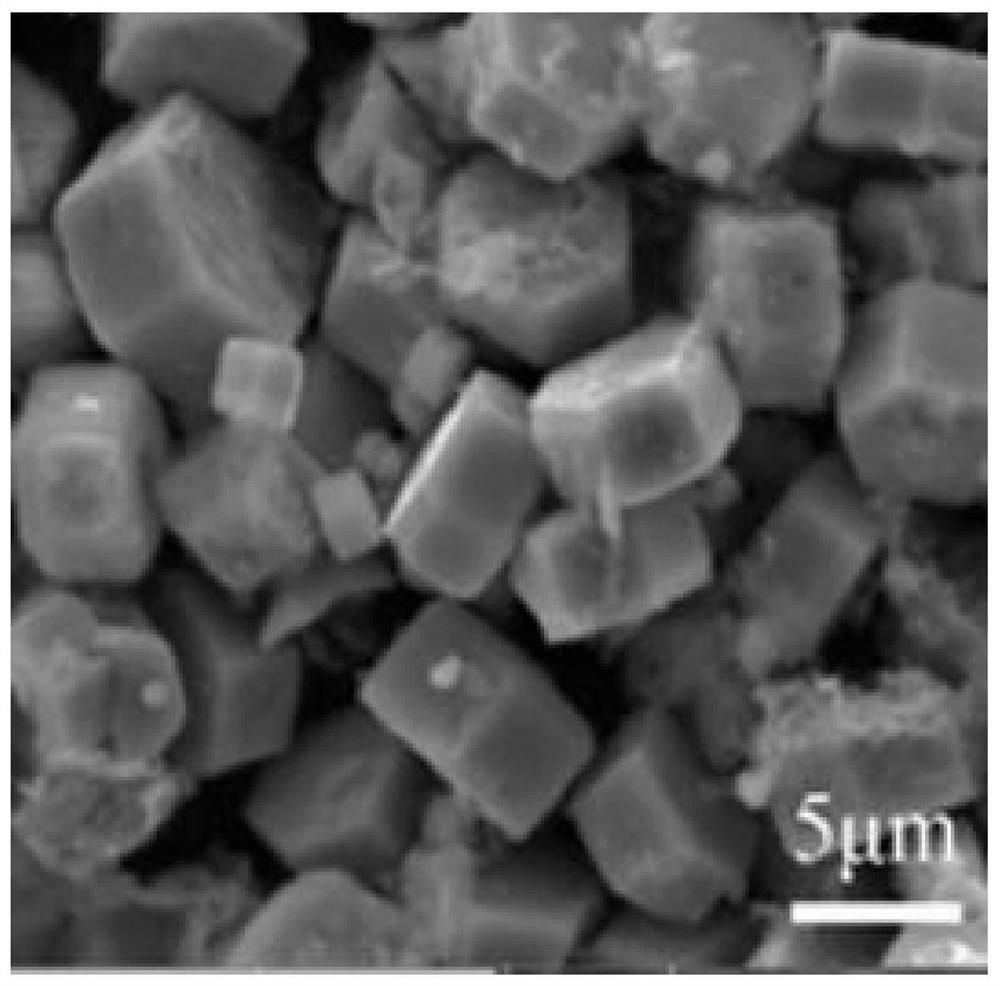

Embodiment 1

[0031] First weigh 79.9g of titanium dioxide, 245.871g of niobium pentoxide, 13.65g of vanadium pentoxide, 16.97g of sucrose and 3.39g of sodium dodecylbenzenesulfonate, and disperse the above raw materials in 840g of deionized water , made into a suspension with a solid content of 30%; then the above suspension was added to the reaction kettle, heated to 200°C for 15 hours under airtight conditions, after the reaction was completed and cooled to room temperature, washed, filtered and dried to obtain titanium niobate Body powder; then the obtained titanium niobate precursor powder is roasted at a high temperature for 8 hours under the protection of nitrogen atmosphere, the roasting temperature is 600°C, and then cooled to room temperature to obtain a hexagonal prism-shaped titanium niobate negative electrode material, whose molecular formula is TiNb 1.85 V 0.15 o 7 / C.

Embodiment 2

[0035] First weigh 340.32g of tetrabutyl titanate, 537.644g of niobium chloride, 0.4g of magnesium oxide, 87.84g of glucose and 43.92g of triton, and disperse the above raw materials in 1515g of deionized water to form a solid Suspension with a content of 40%; then add the above suspension into a reaction kettle, heat to 150°C under airtight conditions and react for 5 hours, after the reaction is completed and cooled to room temperature, wash, filter and dry to obtain titanium niobate precursor powder; Then, the obtained titanium niobate precursor powder was roasted at a high temperature for 5 hours under the protection of nitrogen atmosphere, the roasting temperature was 800°C, and then cooled to room temperature to obtain a hexagonal prism-shaped titanium niobate negative electrode material, whose molecular formula was TiNb 1.99 Mg 0.01 o 7 / C.

Embodiment 3

[0037] First weigh 120g of titanic acid, 212.34g of niobium dioxide, 15.294g of aluminum oxide, 52.14g of polysaccharide and 34.76g of triton, and disperse the above raw materials in 1738g of deionized water to form a solid Suspension with a content of 20%; then add the above suspension into a reaction kettle, heat to 250° C. for 10 h under airtight conditions, and after the reaction is completed and cool to room temperature, wash, filter and dry to obtain titanium niobate precursor powder; Then, the obtained titanium niobate precursor powder was roasted at a high temperature for 2 hours under the protection of nitrogen atmosphere, the roasting temperature was 1000°C, and then cooled to room temperature to obtain a hexagonal prism-shaped titanium niobate negative electrode material, whose molecular formula was TiNb 1.7 al 0.3 o 7 / C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com