A kind of separation method of propylene/propane

A separation method and propane technology, applied in the field of chemical materials, can solve the problems of high energy consumption, difficult separation, and inability to separate propane and propylene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

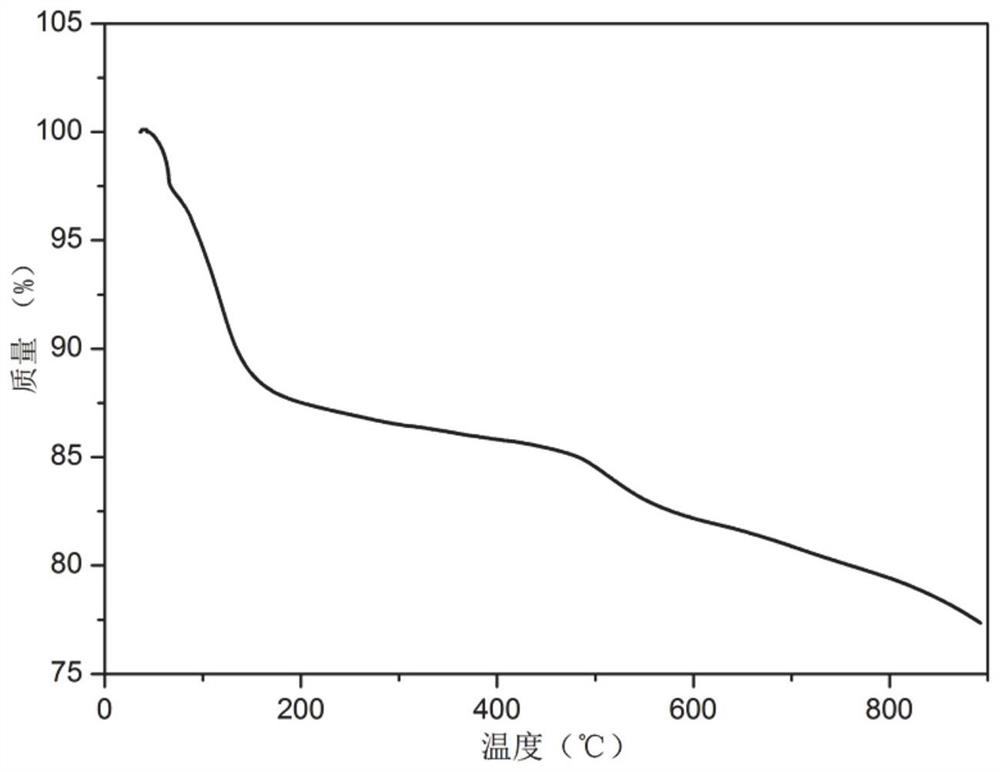

[0065] First, 10g FAU type 13X molecular sieve (SiO 2 / Al 2 o 3 =2.47), under the condition of water bath at 60°C, ion exchange was carried out with 400ml concentration of 1M zinc nitrate aqueous solution for 2h, washed and dried. The exchanged molecular sieve was reacted with 14 g of 2-methylimidazole at 60°C for 4 hours, washed with deionized water until neutral, and dried to obtain an adsorbent, marked as 1#. Under the conditions of 25°C and 100KPa, the adsorption capacity of propylene and propane of the obtained product are respectively 10.45cm 3 / g and 3.65cm 3 / g, the equilibrium separation ratio of propylene propane is 2.86.

Embodiment 2

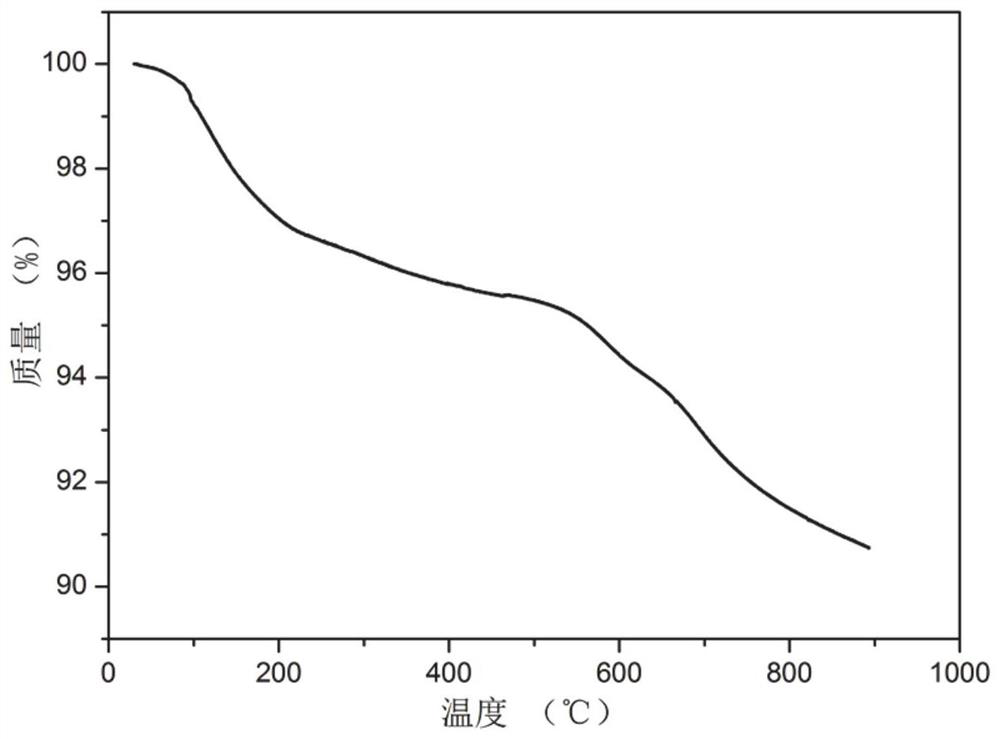

[0067] First, 10g FAU type Na-Y molecular sieve (SiO 2 / Al 2 o 3 =5.45), under the condition of water bath at 60°C, ion exchange was carried out with 400 ml of 1M copper chloride aqueous solution for 4 hours, washed and dried. The exchanged molecular sieves were reacted with 16 g of 2-ethylimidazole at 60°C for 4 hours, washed with deionized water until neutral, and dried to obtain an adsorbent, marked as 2#. Under the conditions of 25°C and 100KPa, the adsorption capacity of propylene and propane of the obtained product are respectively 11.35cm 3 / g and 3.96cm 3 / g, the equilibrium separation ratio of propylene propane is 2.87.

Embodiment 3

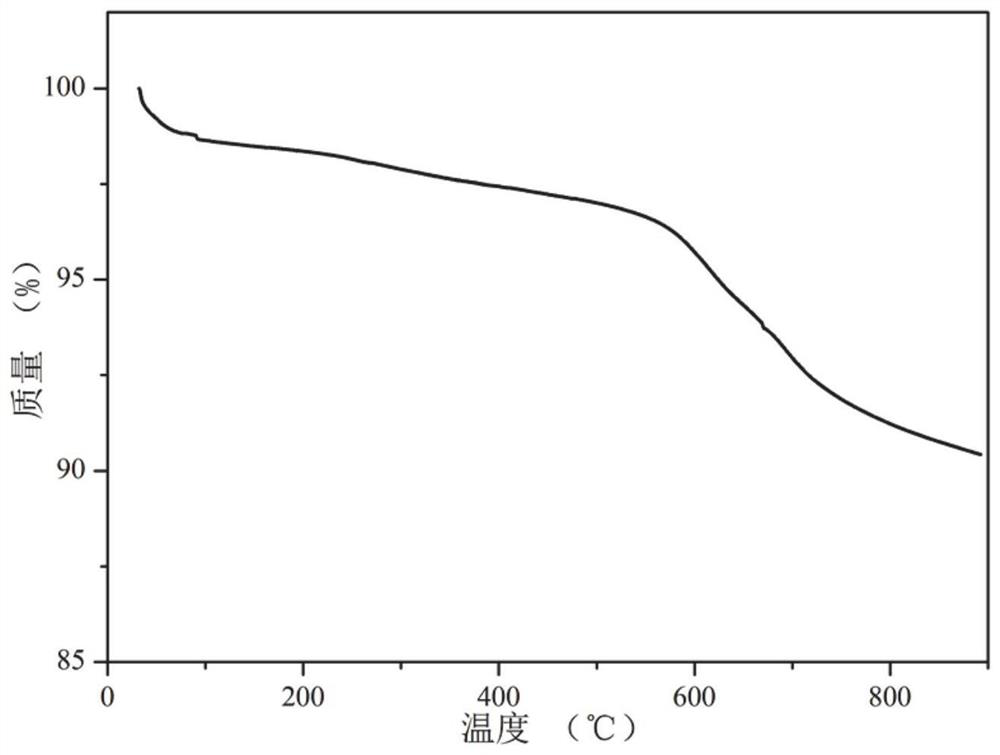

[0069] First, 10g of MOR molecular sieve (SiO 2 / Al 2 o 3 =13.76), under the condition of water bath at 50°C, ion exchange was carried out with 400ml concentration of 1M indium nitrate aqueous solution for 8h, washed and dried. The exchanged molecular sieves were reacted with 18 g of 2-ethylimidazole at 60°C for 4 hours, washed with deionized water until neutral, and dried to obtain an adsorbent, marked as 3#. Under the conditions of 25°C and 100KPa, the adsorption capacity of propylene and propane of the obtained product are respectively 19.66cm 3 / g and 4.57cm 3 / g, the equilibrium separation ratio of propylene propane is 4.3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com