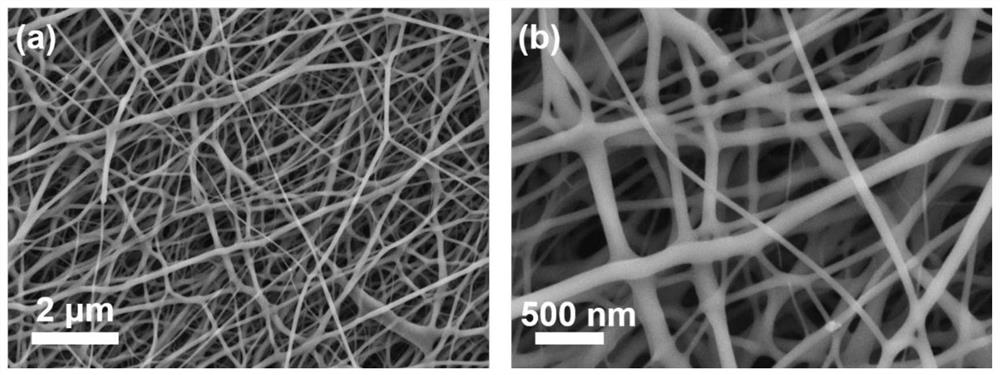

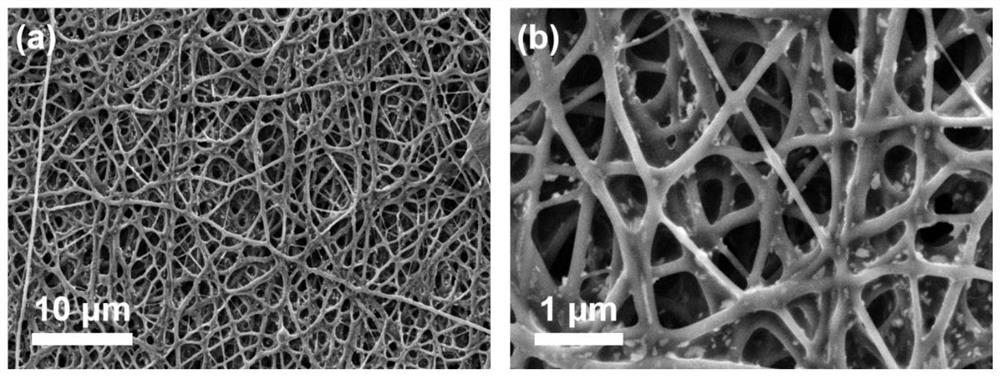

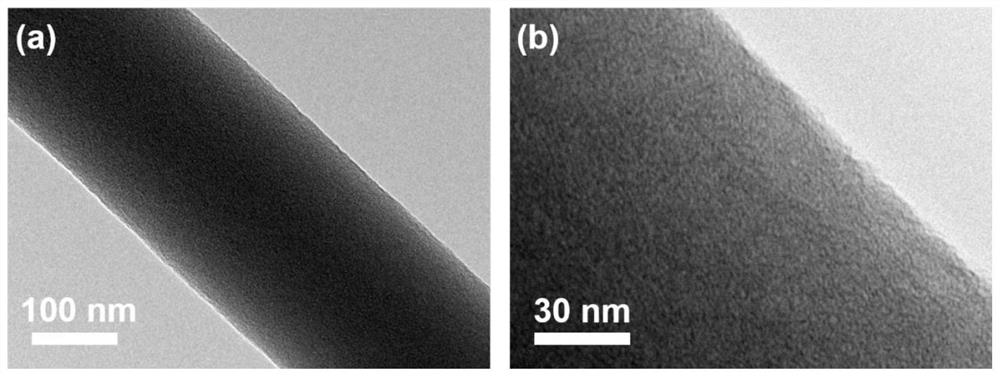

Waste silk-based flexible carbon nanofiber membrane and preparation method thereof

A carbon nanofiber, nanofiber membrane technology, applied in fiber processing, rayon manufacturing, fiber chemical characteristics, etc., can solve the problems of low comprehensive utilization rate of waste silk, environmental pollution, waste of resources, etc., and achieve easy control of reaction conditions and The effect of realizing, avoiding environmental pollution and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A method for preparing a waste silk-based flexible carbon nanofiber film, the specific steps of the method are as follows:

[0056] (1) Pre-treatment of waste silk:

[0057] Ⅰ. Dissolve 2 g of sodium carbonate, 2 g of sodium bicarbonate, and 1 g of soap in 500 mL of deionized water, add 10 g of discarded cocoons, and degumming-refining at 95 °C for 1 h to obtain silk fibroin.

[0058] Ⅱ. Dissolve 5 g of anhydrous calcium chloride in 100 g of formic acid, then add 10 g of silk fibroin, and stir at room temperature for 5 h to obtain a silk fibroin solution.

[0059] Ⅲ. Pour the silk fibroin solution into a dialysis bag (molecular weight cut-off: 8000-14000 Da), dialyze with deionized water for 3 days, remove calcium chloride and formic acid by centrifugation, and obtain pure silk fibroin.

[0060] Ⅳ. The pure silk fibroin solution after dialysis was frozen at -25°C for 24 hours, and then freeze-dried at a temperature of -50°C and a pressure of 40 Pa for 24 hours to obtai...

Embodiment 2

[0065] A method for preparing a waste silk-based flexible carbon nanofiber film, the specific steps of the method are as follows:

[0066] (1) Pre-treatment of waste silk:

[0067] Ⅰ. Dissolve 2 g of sodium carbonate, 2 g of sodium bicarbonate, and 1 g of soap in 500 mL of deionized water, add 10 g of discarded cocoons, and degumming-refining at 95 °C for 1 h to obtain silk fibroin.

[0068] Ⅱ. Dissolve 5 g of anhydrous calcium chloride in 100 g of formic acid, then add 10 g of silk fibroin, and stir at room temperature for 5 h to obtain a silk fibroin solution.

[0069] Ⅲ. Pour the silk fibroin solution into a dialysis bag (molecular weight cut-off: 8000-14000 Da), dialyze with deionized water for 3 days, remove calcium chloride and formic acid by centrifugation, and obtain pure silk fibroin.

[0070] Ⅳ. The pure silk fibroin solution after dialysis was frozen at -25°C for 24 hours, and then freeze-dried at a temperature of -50°C and a pressure of 40 Pa for 24 hours to obtai...

Embodiment 3

[0075] A method for preparing a waste silk-based flexible carbon nanofiber film, the specific steps of the method are as follows:

[0076] (1) Pre-treatment of waste silk:

[0077] Ⅰ. Dissolve 2 g of sodium carbonate, 2 g of sodium bicarbonate, and 1 g of soap in 500 mL of deionized water, add 10 g of waste silk fiber, and degumming-refining at 95 °C for 1 h to obtain silk fibroin.

[0078] Ⅱ. Dissolve 5 g of anhydrous calcium chloride in 100 g of formic acid, then add 10 g of silk fibroin, and stir at room temperature for 5 h to obtain a silk fibroin solution.

[0079] Ⅲ. Pour the silk fibroin solution into a dialysis bag (molecular weight cut-off: 8000-14000 Da), dialyze with deionized water for 3 days, remove calcium chloride and formic acid by centrifugation, and obtain pure silk fibroin.

[0080] Ⅳ. The pure silk fibroin solution after dialysis was frozen at -25°C for 24 hours, and then freeze-dried at a temperature of -50°C and a pressure of 40 Pa for 24 hours to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com