Molecular sieve catalyst and preparation method and application thereof

A molecular sieve and catalyst technology, which is applied in the field of molecular sieve catalyst and its preparation, can solve the problems of difficulty in normal operation of the device, shutdown and other problems, and achieve the effects of good activity and propylene selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Weigh 10.0g of hydrogen-type ZSM-5 with a silicon-aluminum ratio of 200 (produced by Shanghai Fuxu Molecular Sieve Co., Ltd.), 2.0g of polycrystalline mullite fiber (Zhejiang Deqing Lanya Crystal Fiber Co., Ltd., with an average fiber diameter of 3 microns and a length of 150mm), sodium water glass 20.0g (Beijing Yongfei Adhesive Factory, SiO 2 content 26.0%, n=3.2), 1.0 g of scallop powder, after mixing evenly, extrusion molding. The molded product was dried in the shade at room temperature for 96 hours, and then dried at 80°C. The dried product was calcined at 550° C. for 5 hours to obtain a catalyst intermediate product.

[0042] Weigh 10.0 g of the above-mentioned catalyst intermediate product and add it into 80 mL of ammonium nitrate solution, exchange at a temperature of 80° C., and exchange for 3 times, each time for 8 hours. Then, the resulting product was filtered, followed by drying at 100°C. Then the dried product was calcined at 550° C. for 8 hours to obt...

Embodiment 2-7

[0044] Add a certain amount of hydrogen-type ZSM-5 raw powder with a silicon-aluminum ratio of 100-1000, add a certain amount of inorganic fiber, silicate binder, and molding aids, and extrude into a strip. The molded product was dried in the shade at room temperature for 72 hours, and then dried at 80°C. The dried product was calcined at 550° C. for 5 hours to obtain a catalyst intermediate product.

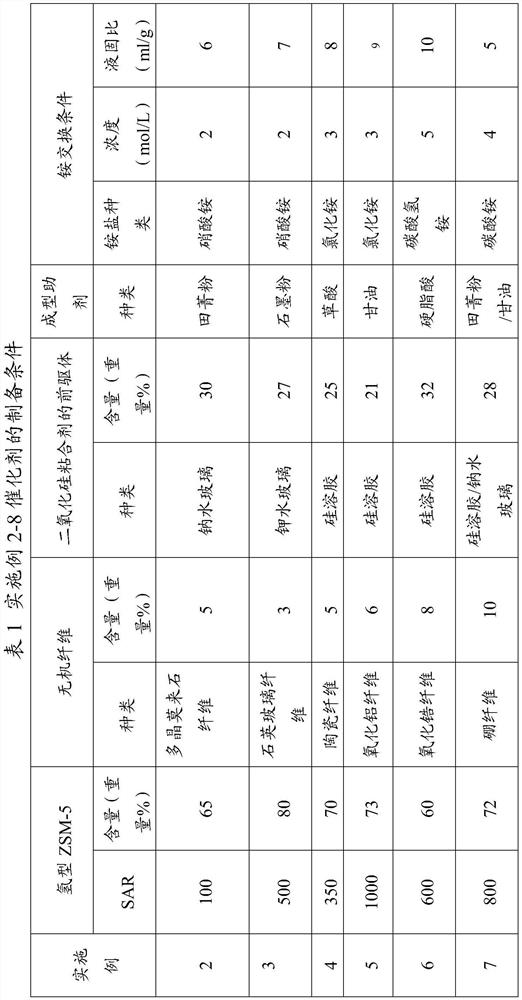

[0045]The above-mentioned catalyst intermediate product was added into the ammonium ion-containing solution, and exchanged three times at a temperature of 100° C., each time for 8 hours. Then, the resulting product was filtered, followed by drying at 100°C. Then the dried product was calcined at 550° C. for 8 hours to obtain the catalysts of Examples 2-8, and the various ingredients and contents are listed in Table 1.

[0046]

Embodiment 8

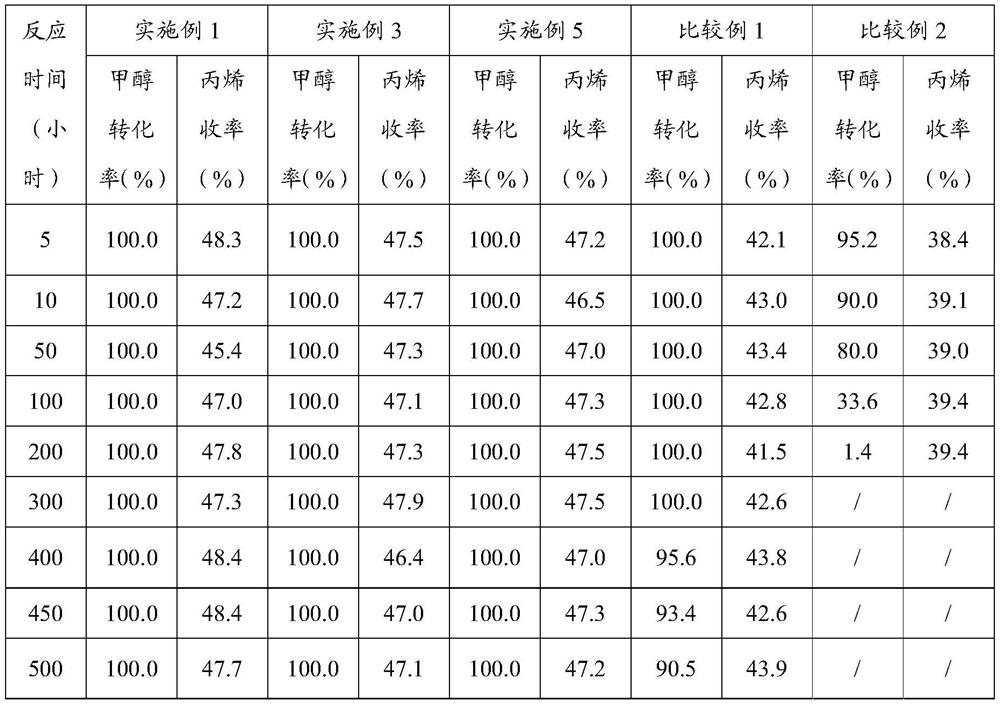

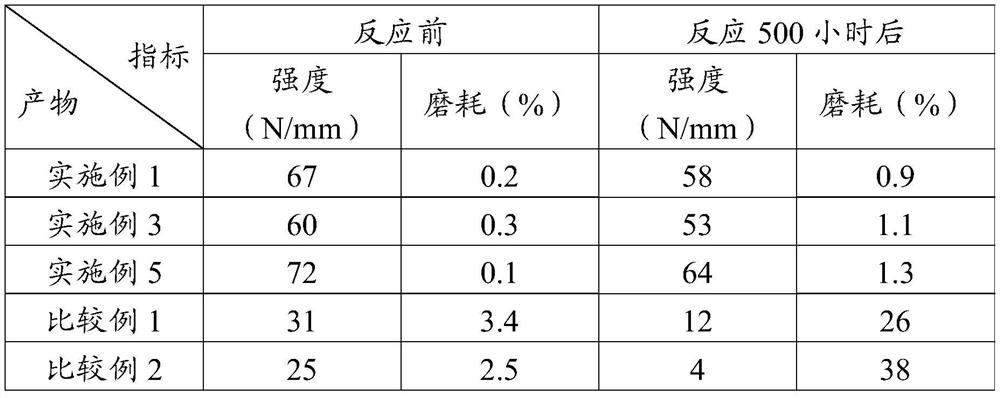

[0055] The catalyst reaction performance evaluation device of the present invention adopts a fixed-bed flow reactor, and the loading amount of catalyst for each evaluation is 3.0 g, with 50% by weight methanol-water as raw material, at 480 ° C, the liquid hourly space velocity is 1 h -1 , the total system pressure is less than 0.05MPa, the product is analyzed online by gas chromatography with HP-PLOT-Q column, and the product is finally normalized and expressed by the mass content of carbon base. In addition, in order to characterize the high-temperature anti-burst performance of the catalyst, the extruded catalyst was evaluated for its reaction performance for 500 hours and then tested for its strength and abrasion. The attrition of catalyst was measured in KM-4 particle abrasion tester (Suzhou Qile Electronic Technology Co., Ltd., 40r / min), and the strength test was carried out in YPD-300C tablet hardness tester (Shanghai Huanghai Drug Inspection Instrument Co., Ltd., catalys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com