Method for preparing solid-phase carbon quantum dots by adopting biological collagen waste and application of solid-phase carbon quantum dots

A technology of carbon quantum dots and biological glue, which is applied in the field of nanomaterial preparation, can solve the problems of difficult purification of liquid phase products, complicated preparation process, and difficult transportation, and achieve good fluorescence properties and modifiability, wide sources, and high safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Carbon source preparation: add 100 g of bovine tendon waste remaining after collagen extraction in the factory to 5 L of 0.5 M acetic acid solution, add 10 g of pepsin, and stir at 4°C for 2 days. Filter the collagen waste after soaking with gauze, and wash thoroughly with deionized water. After cleaning, freeze overnight in a -20°C freezer, then freeze-dry in a freeze dryer for 36 hours, and dry at an oven temperature of 40°C for 8 hours, and finally obtain a white gauze wing-shaped solid that is the carbon source precursor;

[0043] (2) Carbonized carbon source: Weigh 20 g of the carbon source obtained in step (1) and place it in a porcelain boat, and place it in a tube furnace. Under the protection of nitrogen, the temperature is raised from room temperature to 300 ℃ and keep it warm for 6 hours; when the temperature drops to room temperature, take out the porcelain boat to obtain the brown-yellow carbon quantum dot product;

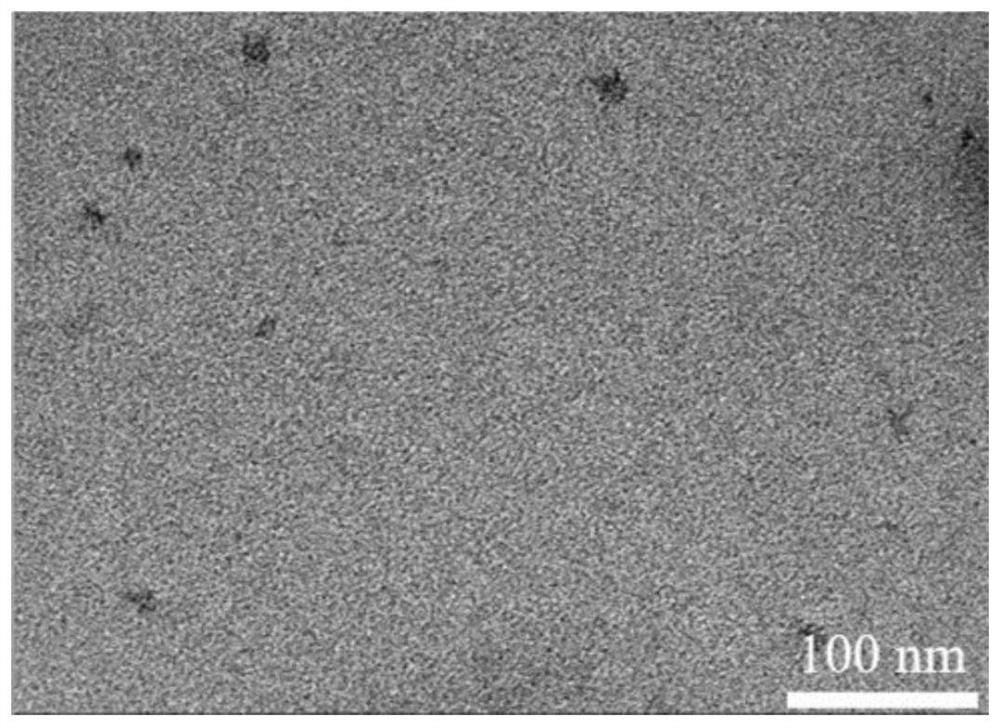

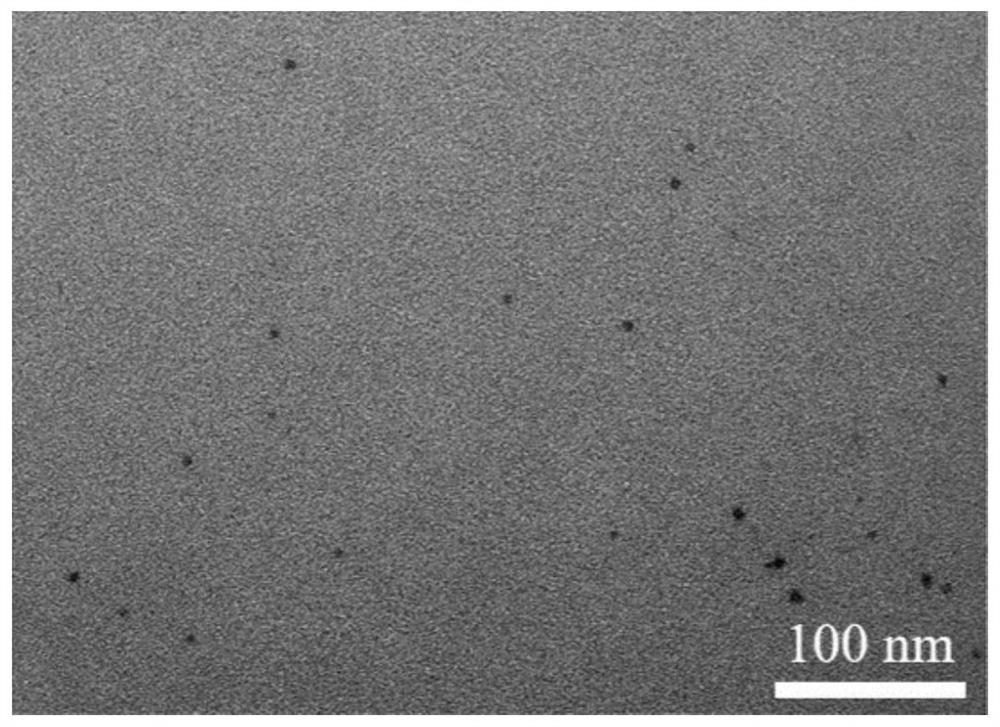

[0044] (3) Purification: Dissolve all...

Embodiment 2

[0046] (1) Preparation of carbon source: Add 100g of rat tail waste left after collagen extraction in the factory to 5L of 0.1M hydrochloric acid-nitric acid mixture (volume ratio 1:1), and add 10g of pepsin, and stir at 4°C 3d. Filter the collagen waste after soaking with gauze, and wash thoroughly with deionized water. After cleaning, freeze overnight in a freezer at -20°C, then freeze-dry in a freeze dryer for 36 hours, and dry at an oven temperature of 50°C for 6 hours, and finally obtain a white gauze wing-shaped solid that is the carbon source precursor;

[0047] (2) Carbonized carbon source: Weigh 20 g of the carbon source obtained in step (1) and place it in a porcelain boat, and place it in a tube furnace. Under the protection of argon, the temperature is raised from room temperature to 400°C and keep it warm for 4 hours; when the temperature drops to room temperature, take out the porcelain boat to get the brown-yellow carbon quantum dot product;

[0048] (3) Purif...

Embodiment 3

[0050] (1) Preparation of carbon source: add 5L of 0.3M nitric acid-silicotungstic acid mixture (volume ratio 3:1) to 100g of mixed waste of bovine tendon, rat tail, and fish skin after extracting collagen from the factory, and add 10g of pepsin, stirred at 4°C for 5d. Remove the remaining large pieces of tissue and then filter with gauze to obtain the enzymatic hydrolysis and acidification product, which is fully washed with deionized water. After cleaning, freeze overnight in a -20°C freezer, then freeze-dry for 48 hours in a lyophilizer, and dry at an oven temperature of 60°C for 4 hours, and finally obtain a white gauze wing-like solid that is the carbon source precursor;

[0051] (2) Carbonized carbon source: Weigh 20g of the carbon source obtained in step (1) and place it in a porcelain boat, and place it in a tube furnace, and raise the temperature to 600°C at a rate of 10°C / min under the protection of argon And keep it warm for 2 hours; when the temperature drops to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com