Molecular sieve containing rare earth elements and production method thereof

A rare earth element and production method technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of weak catalytic ability of molecular sieves, achieve excellent hydrothermal aging resistance, large specific surface area, good The effect of catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

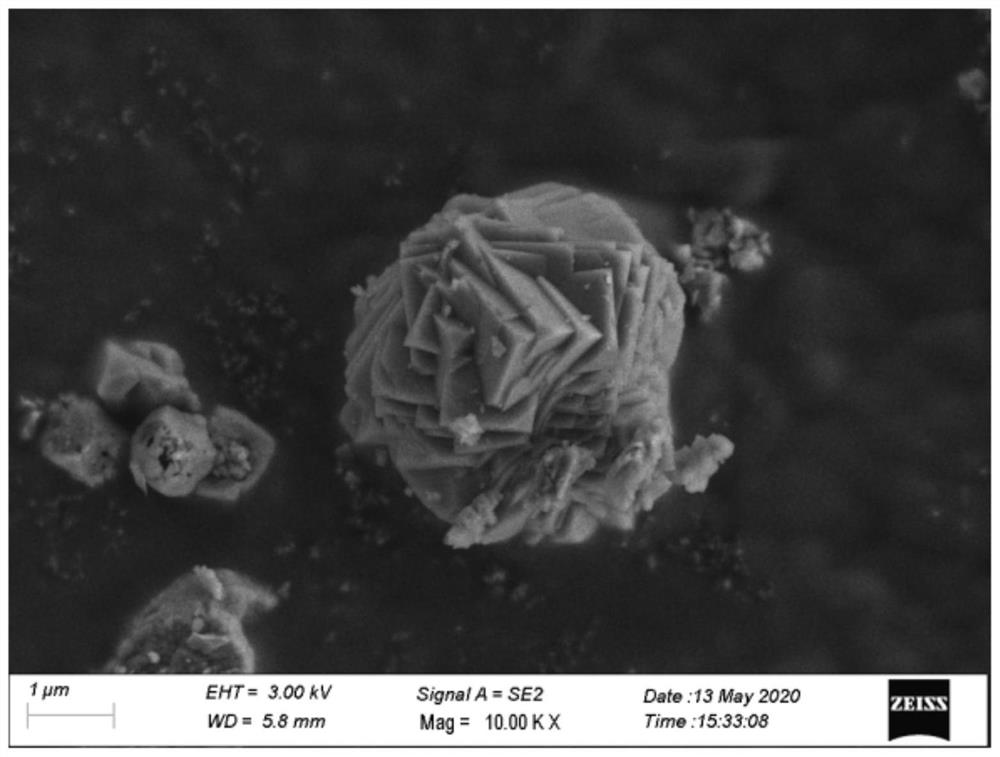

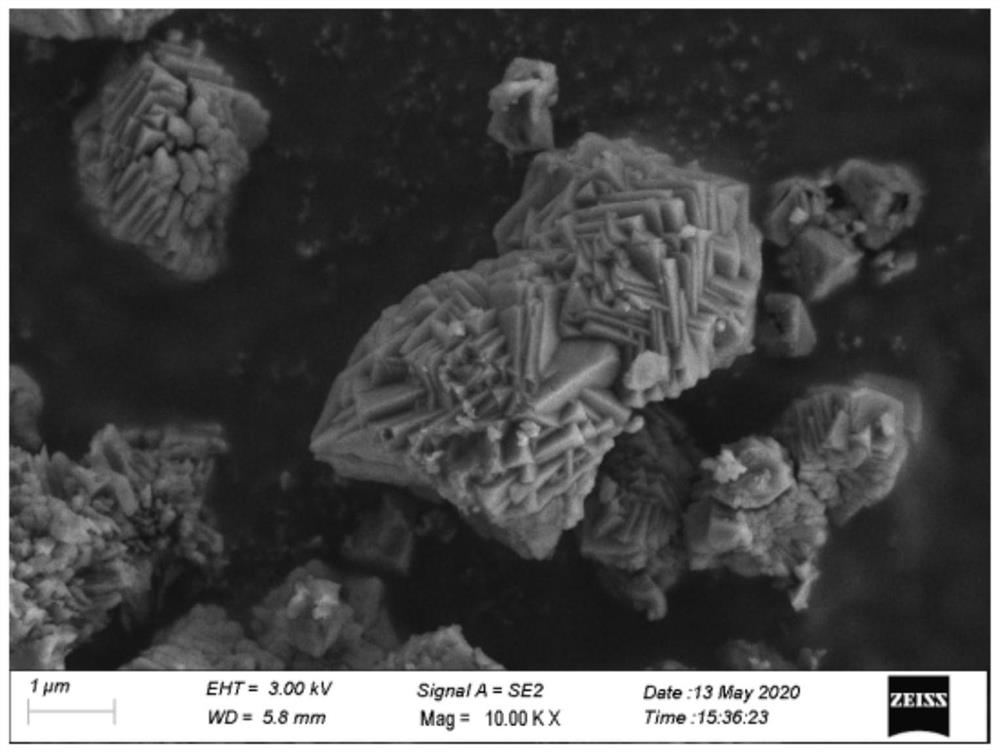

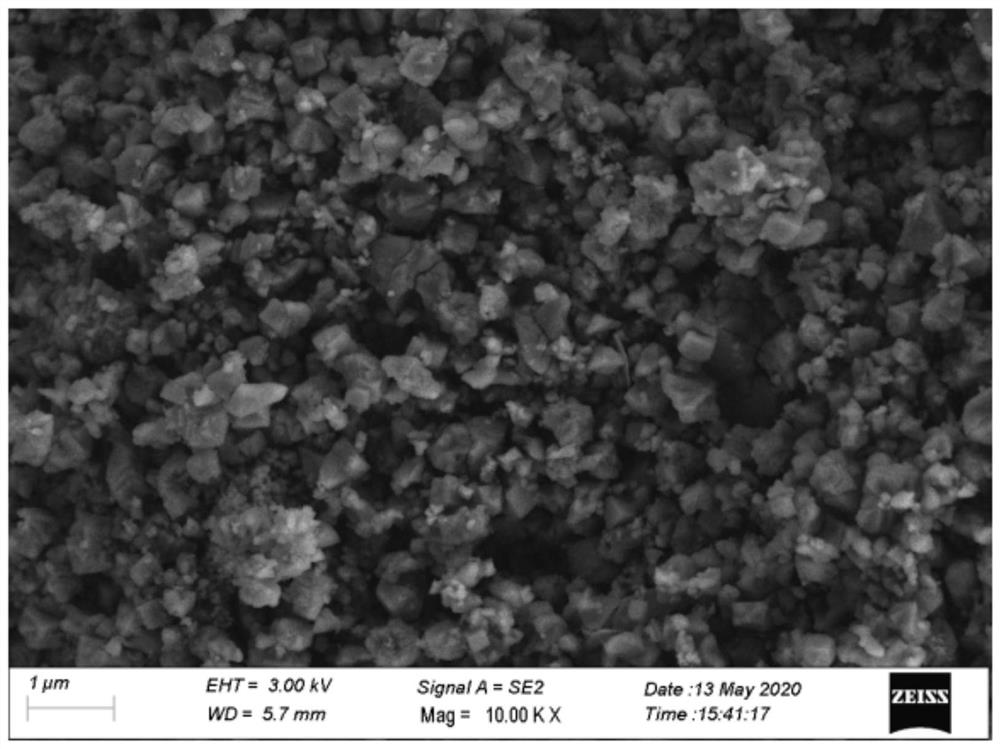

Image

Examples

preparation example Construction

[0047] The preparation method of the molecular sieve containing rare earth elements of the present invention comprises the following steps: (1) a hydrothermal reaction step; (2) a roasting step. The composition and properties of the obtained rare earth element-containing molecular sieve are as described above. Detailed description will be given below.

[0048] The steps of the hydrothermal reaction

[0049] The molecular sieve framework mixture including silicon source, aluminum source, template agent, organic base and water is subjected to the first hydrothermal reaction to obtain the first reaction product; after the first reaction product, ammonium source and copper source are mixed, the second hydrothermal reaction is carried out thermal reaction to obtain a second reaction product; after mixing the second reaction product with a rare earth source, perform a third hydrothermal reaction to obtain a third reaction product.

[0050] The aluminum source of the present inve...

Embodiment 1

[0076] 28.4g of 25wt% aqueous solution of N,N,N-trimethyladamantane ammonium, 3.1g of sodium ethoxide and 85g of water were heated to reflux at a temperature of 40°C and stirred evenly to form a mixture A; A, 1.17g sodium metaaluminate and 32.9g silica sol (solid content is 20wt%, pH is 3.2, and density is 1.2g / cm 3 , with a particle size of 11 nm) was stirred and mixed for 2 hours to form a molecular sieve framework mixture; the molecular sieve framework mixture was subjected to a first hydrothermal reaction at 110° C. for 2 days to obtain a first reaction product.

[0077] Lower the temperature of the first reaction product to 25°C; stir and mix the cooled first reaction product with 3.43g of ammonium nitrate for 8 hours, then stir and mix with 8.9g of chelated copper glutamic acid for 3 hours, then carry out the second reaction at 80°C. Two hydrothermal reaction 10h, to obtain the second reaction product.

[0078] After stirring and reacting the second reaction product with ...

Embodiment 2

[0081] 34.4g concentration is 25wt% the aqueous solution of N,N,N-trimethyladamantane ammonium, 5.25g concentration is 20wt% tetraethylammonium hydroxide and 85g water under heating reflux, temperature is under the condition of 30 ℃ Stir evenly to form mixture A; Mix mixture A, 7.28g aluminum sol (solid content is 10wt%, pH is 4, viscosity is 43mPa·s, particle diameter is 10nm) and 28.5g silica sol (solid content is 20wt%, pH 5.6, the density is 1.5g / cm 3 , with a particle size of 11nm) was stirred and mixed for 3 hours to form a molecular sieve framework mixture; the molecular sieve framework mixture was subjected to a first hydrothermal reaction at 130° C. for 3 days to obtain a first reaction product.

[0082] Lower the temperature of the first reaction product to 25°C; stir and mix the cooled first reaction product with 4.57g of ammonium nitrate for 8 hours, then stir and mix with 8.6g of copper acetate for 3 hours, then carry out the second hydrothermal reaction at 70°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com