Steel slag doped premixed concrete and preparation method thereof

A technology for ready-mixed concrete and steel slag, applied in the field of building materials, can solve the problems of consuming large fossil energy, aggravating the greenhouse effect, affecting the ecological environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

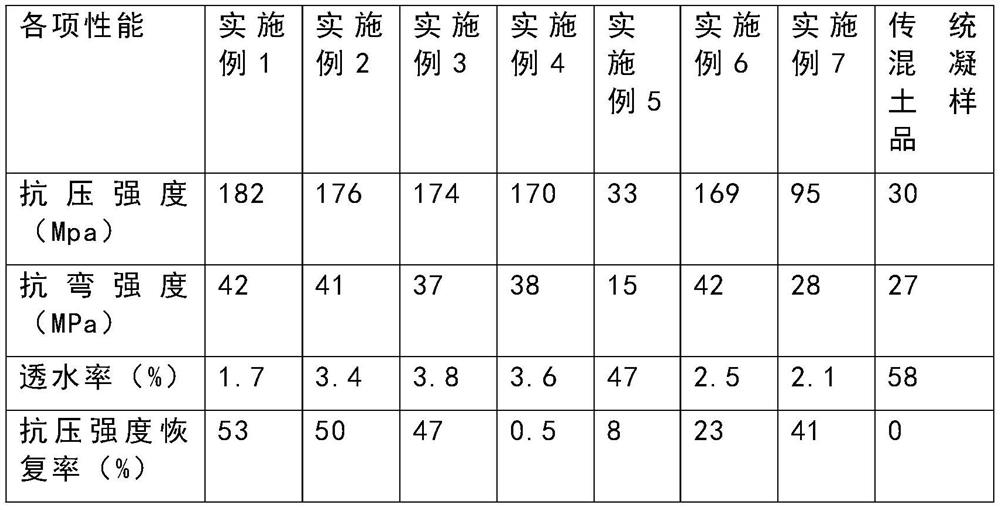

Examples

Embodiment 1

[0056] S1 Preparation of microbial bacterial liquid: mix peptone, beef extract, urea, and yeast extract to make microbial nutrient solution, pour the microbial nutrient solution into the cultured Bacillus subtilis bacterial liquid, stir for 1 min, and obtain microbial bacterial liquid;

[0057] S2 prepares modified fiber;

[0058] A. Preparation of porous fibers: add distilled water to polyvinyl alcohol, heat to 85°C, stir at 300r / min for 0.5h, cool down to 55°C, add hydrochloric acid, when the pH value is 1, add citral, and crosslinking reaction 1.5h, continue to heat up to 85°C, add nano-silicon nitride particles, calcium carbonate, hydrochloric acid, rubber powder and steel slag, stir at 800r / min for 25min, and make porous fibers by electrospinning;

[0059] B. Modification of the porous fiber: Soak the porous fiber in the silicon coupling agent for 4 hours, take it out and dry it, soak it in the microbial bacterial solution for 1 hour, take it out and dry it at 35°C for 1 ...

Embodiment 2

[0070] S1 Preparation of microbial bacterial liquid: mix peptone, beef extract, urea, and yeast extract to make microbial nutrient solution, pour the microbial nutrient solution into the cultured Bacillus subtilis bacterial liquid, stir for 1.5min, and obtain microbial bacterial liquid;

[0071] S2 prepares modified fiber;

[0072] A. Preparation of porous fibers: add distilled water to polyvinyl alcohol, heat to 90°C, stir at 300r / min for 1h, cool down to 60°C, add hydrochloric acid, when the pH value is 2, add citral, crosslinking reaction for 2h , continue to heat up to 90°C, add nano-silicon nitride particles, calcium carbonate, hydrochloric acid, rubber powder and steel slag, stir at 800r / min for 35min, and make porous fibers by electrospinning;

[0073] B. Modify the porous fiber: Soak the porous fiber in the silicon coupling agent for 5 hours, take it out and dry it, soak it in the microbial bacterial solution for 1.5 hours, take it out and dry it at 37°C for 1.5 hours,...

Embodiment 3

[0084] S1 Preparation of microbial bacterial liquid: mix peptone, beef extract, urea, and yeast extract to make microbial nutrient solution, pour the microbial nutrient solution into the cultured Bacillus subtilis bacterial liquid, stir for 2 minutes, and obtain microbial bacterial liquid;

[0085] S2 prepares modified fiber;

[0086] A. Preparation of porous fibers: add distilled water to polyvinyl alcohol, heat to 95°C, stir at 300r / min for 1.5h, cool down to 65°C, add hydrochloric acid, when the pH value is 3, add citral, crosslinking reaction 2.5h, continue to heat up to 95°C, add nano-silicon nitride particles, calcium carbonate, hydrochloric acid, rubber powder and steel slag, stir at 800r / min for 45min, and make porous fibers by electrospinning;

[0087] B. Modification of the porous fiber: Soak the porous fiber in the silicon coupling agent for 6 hours, take it out and dry it, soak it in the microbial bacterial solution for 2 hours, take it out and dry it at 40°C for 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com