Anti-radiation fiber based on nano material and preparation method thereof

A technology of radiation-proof fibers and nanomaterials, applied in the chemical characteristics of fibers, protective clothing, rayon manufacturing, etc., can solve the problems of affecting the smoothness of fibers, poor washing fastness, and high prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

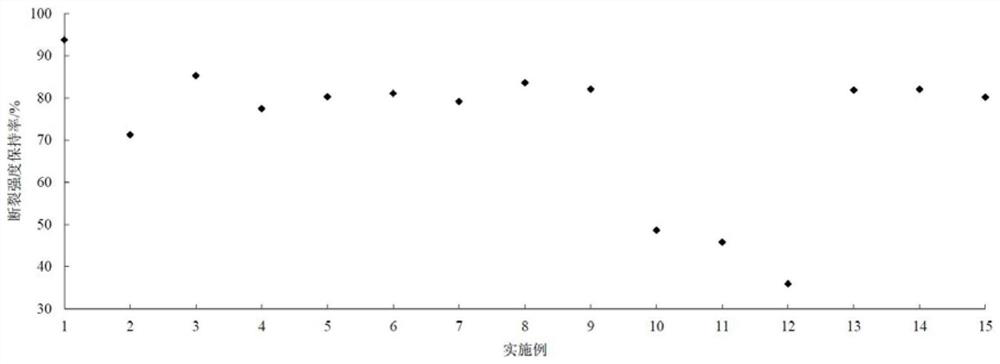

Examples

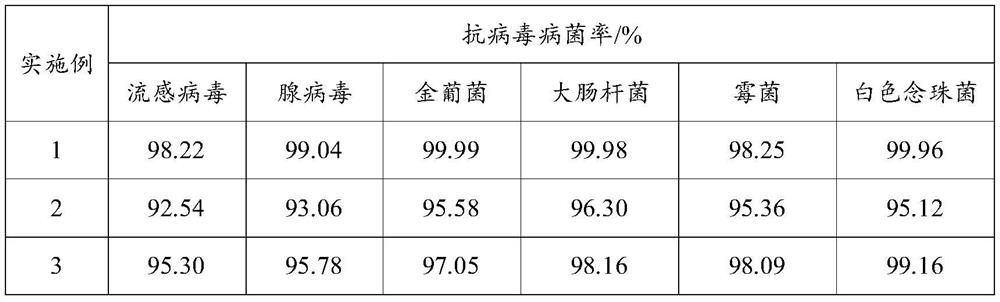

Embodiment 1

[0065] Embodiment 1: A kind of anti-radiation fiber based on nanomaterials:

[0066] This embodiment provides a radiation-proof fiber based on nanomaterials, the components and weight percentages of the radiation-proof cellulose include:

[0067] Activated carbon resin loaded with nano zinc oxide 25.0%;

[0068] Yttrium doped zinc ferrite 1.0%;

[0069] Polyester chips 74.0%;

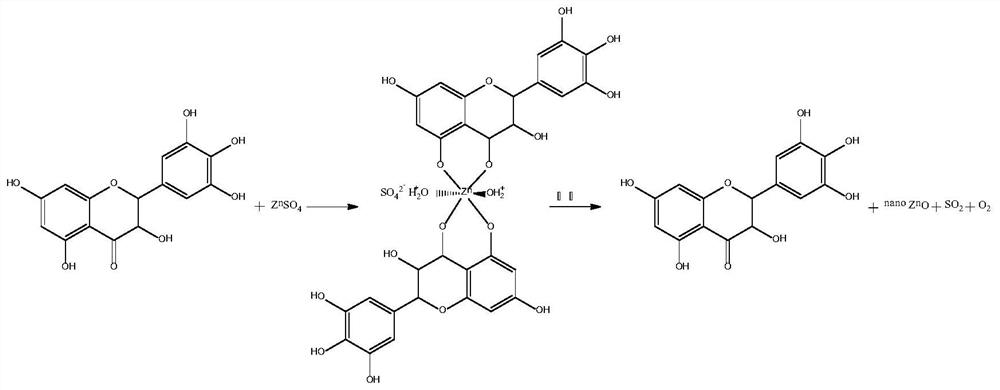

[0070] Wherein, the nano-zinc oxide is prepared using dihydromyricetin as a template, and

[0071] The weight ratio of nano zinc oxide to yttrium doped zinc ferrite is 1:25.

[0072] The anti-radiation fiber based on nanomaterials described in this example is prepared by a method comprising the following steps:

[0073] 1) Preparation of activated carbon resin loaded with nano zinc oxide:

[0074] 1.1) According to the weight ratio of 100:5:0.5, the waste coffee grounds, nano-titanium dioxide, and silver ions are mixed evenly, and then vinyltrimethoxysilane with a total solid content of 1.8wt% is a...

Embodiment 2

[0083] Embodiment 2: Another kind of anti-radiation fiber based on nanomaterials:

[0084] This embodiment provides another anti-radiation fiber based on nanomaterials. The composition, proportion and preparation method of the anti-radiation fiber are basically the same as those in Example 1, except that in this embodiment, the anti-radiation fiber The activated carbon resin loaded with nano zinc oxide is not added to the components, and the deficiency is made up with polyester chips.

Embodiment 3

[0085] Embodiment 3: Another kind of anti-radiation fiber based on nanomaterials:

[0086] This embodiment provides another anti-radiation fiber based on nanomaterials. The composition, proportion and preparation method of the anti-radiation fiber are basically the same as in Example 1, except that in this embodiment, the activated carbon resin Without any nanometer zinc oxide or zinc oxide, it is melt-spun with yttrium-doped zinc ferrite and polyester chips.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com