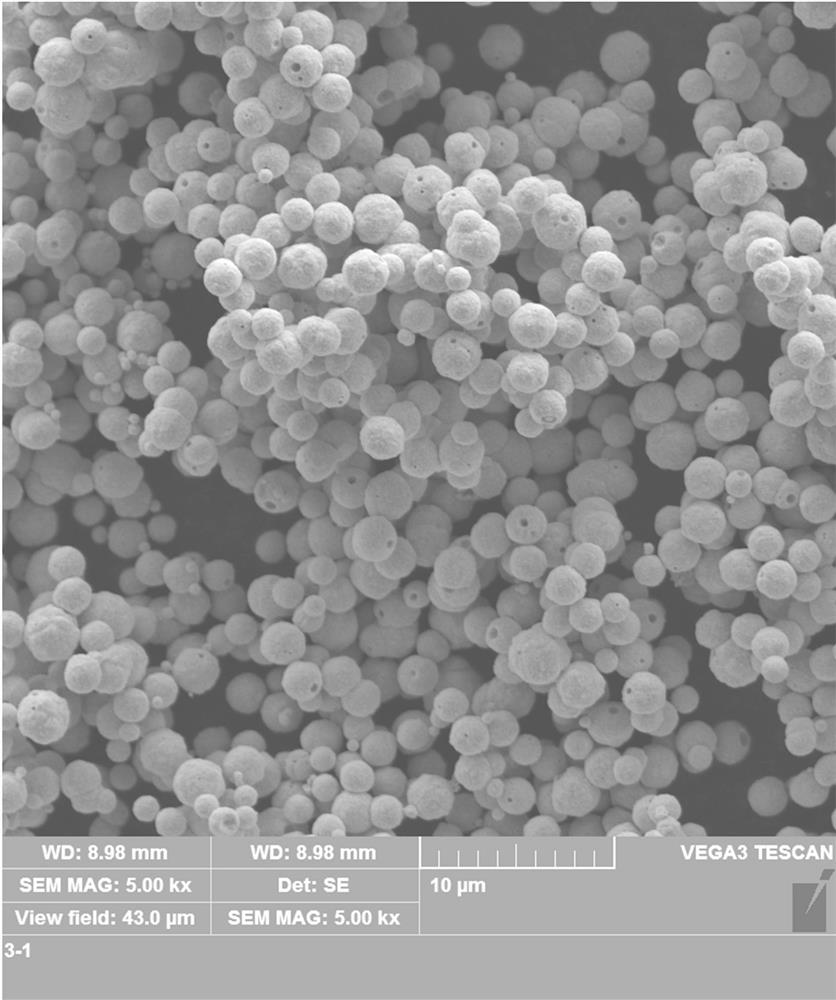

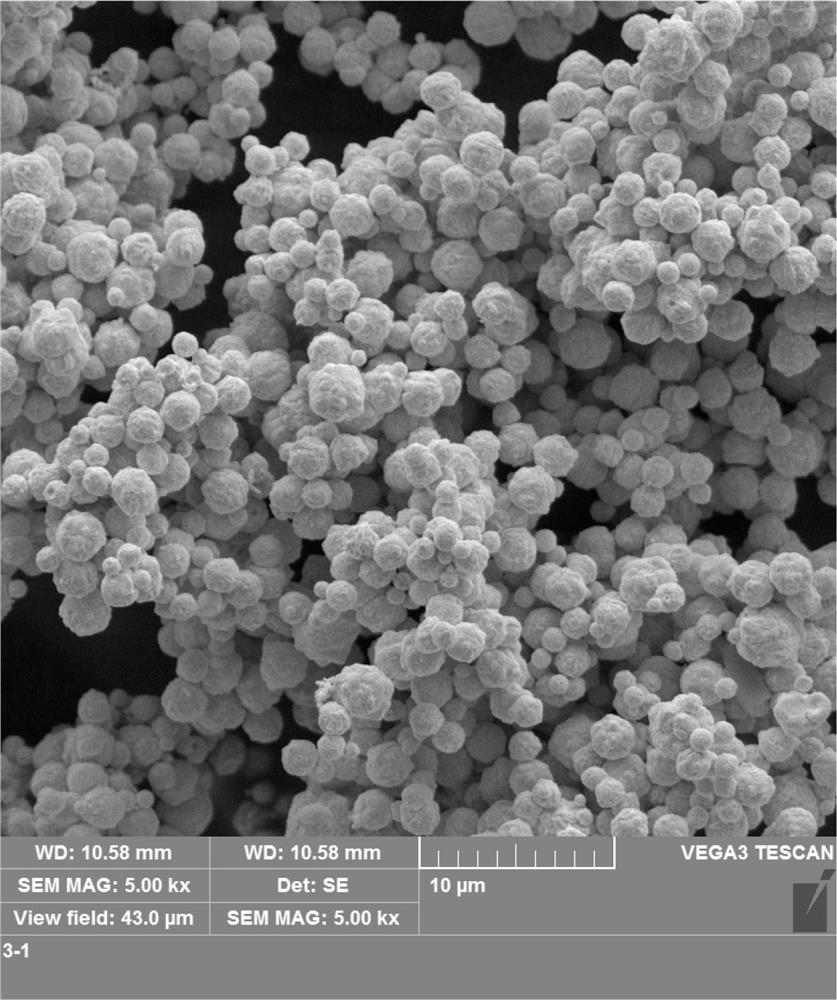

Micron-sized spherical hollow gold powder and preparation method therefor

A micron-scale, spherical technology that can be used in metal processing equipment, transportation and packaging to solve problems such as large shrinkage, foaming, and reduced slurry viscosity stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The preparation method of micron spherical hollow gold powder of the present invention comprises the following steps:

[0048] (1) Adjust the pH value of the chloroauric acid solution to 4~5;

[0049] (2) Add the alcohol solution of the dispersant to the solution obtained in step (1), and stir evenly, wherein the dispersant is selected from C6-C12 saturated fatty acids, n-6 unsaturated fatty acids and n-9 unsaturated fatty acids One or more of them, the mass ratio of dispersant to gold in the reaction system is (0.05-0.2): 1;

[0050] (3) Add the aqueous solution of the reducing agent to the solution obtained in step (2), and stir at a speed of 400-500r / min until the reaction is complete, wherein the mass ratio of the reducing agent to gold in the reaction system is (2-5 ):1;

[0051] (4) Washing and drying the reaction product of step (3), the washing includes washing with lye, thereby preparing the micron-sized spherical hollow gold powder of the present invention. ...

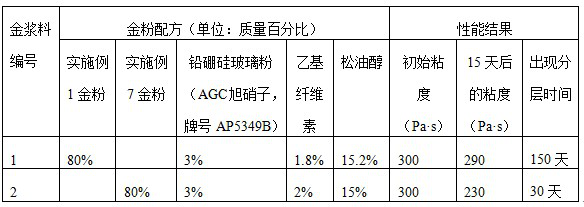

Embodiment 1

[0087] Put 10g of sponge gold with a purity ≥ 99.9% in a 500mL beaker, add 40mL of prepared aqua regia in four times and heat to completely dissolve the pure gold, then add 10mL of concentrated hydrochloric acid to catch the nitrate, and then add deionized water to prepare 20mL concentration is the chloroauric acid solution of 0.5g gold / mL;

[0088] Dissolve 50 g of sodium sulfite completely with 200 mL of deionized water to obtain a sodium sulfite solution;

[0089] Dissolve 1.2g of oleic acid in 6g of absolute ethanol and set aside completely to obtain an oleic acid solution;

[0090] Dissolve 7g of sodium hydroxide with 70mL of deionized water to obtain a 100g / L sodium hydroxide solution;

[0091] Under the stirring condition of 180r / min, slowly pour 20mL sodium hydroxide solution into the 20mL chloroauric acid solution prepared above to adjust the pH value to 4~5. Pour all the solution into the gold-containing solution, stir for 10 minutes; then adjust the speed to 400r / ...

Embodiment 2

[0094] Put 10g of sponge gold with a purity ≥ 99.9% in a 500mL beaker, add 40mL of prepared aqua regia in four times and heat to completely dissolve the pure gold, then add 10mL of concentrated hydrochloric acid to catch the nitrate, and then add deionized water to prepare 20mL concentration is the chloroauric acid solution of 0.5g gold / mL;

[0095] Dissolve 25g of ascorbic acid completely with 125mL of deionized water to obtain ascorbic acid solution;

[0096] Dissolve 0.5g of octanoic acid in 2.5g of absolute ethanol and set aside completely to obtain octanoic acid solution;

[0097] Dissolve 7g of sodium hydroxide with 70mL of deionized water to obtain a 100g / L sodium hydroxide solution;

[0098] Under the stirring condition of 150r / min, slowly pour 20mL sodium hydroxide solution into the 20mL chloroauric acid solution prepared above to adjust the pH value to 4~5. Pour it all into the gold-containing solution, stir for 10 minutes; then adjust the speed to 400r / min, add al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com