NiCrAlY high-temperature sintering ZTA particle reinforced steel-based composite material and preparation method thereof

A particle reinforced, composite material technology, applied in metal material coating technology, metal processing equipment, ion implantation plating and other directions, can solve the problem of poor thermal shock resistance of composite materials, affecting the large-scale application of wear parts, and low bonding strength and other problems, to achieve the effect of enhancing interface bonding, improving room temperature and high temperature strength, and improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A method for preparing NiCrAlY high-temperature sintered ZTA particle-reinforced steel-based composite material of the present invention comprises the following steps:

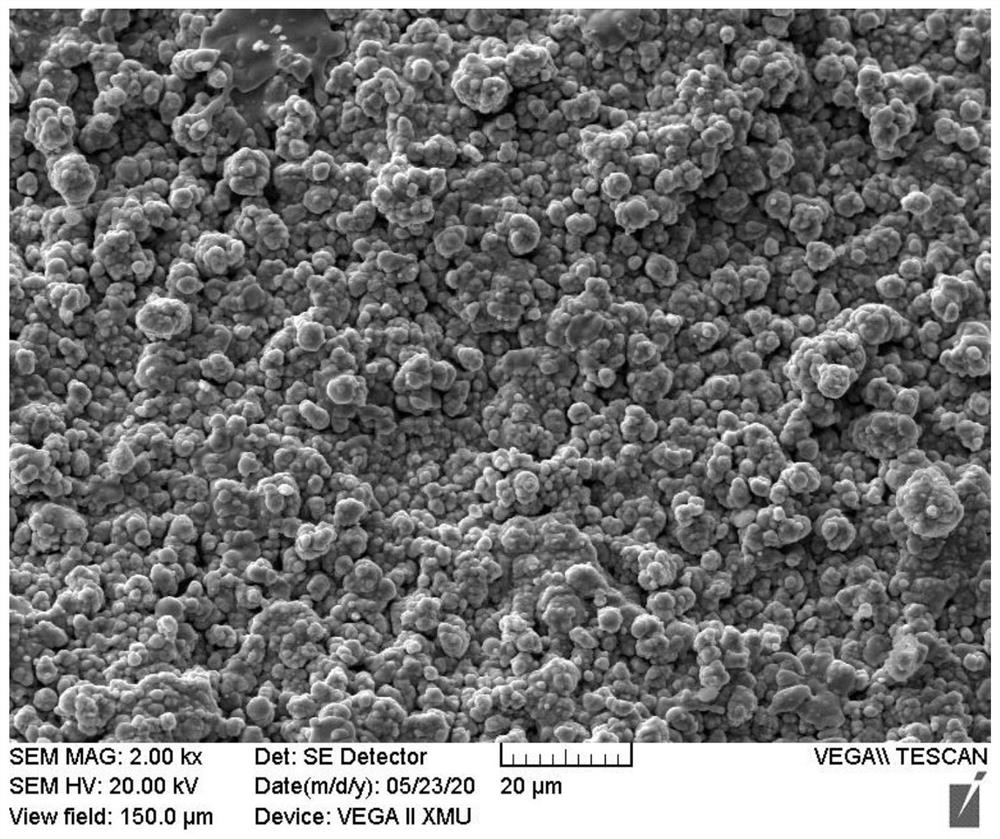

[0036] S1. After drying, ZTA and SiO with a particle size of 4.7-5.5 mm 2Put the particles into a ball mill for low-speed ball milling. The ball milling speed is 75-200r / min, and the ball-milling time is 20-40min, so that the surface of the ZTA particles is slightly roughened. Filter the ZTA particles with a 10-40 mesh screen and wash them with alcohol;

[0037] Before the ball milling treatment, the ZTA particles are soaked in acetone for 20-35 minutes, pickled, then cleaned with acetone by ultrasonic wave for 10-15 minutes, rinsed with deionized water, and dried in a drying oven.

[0038] S2, wet mixing NiCrAlY powder and absolute ethanol to obtain mixed powder The mass ratio of NiCrAlY powder and absolute ethanol is (16~20):1, and the binder is made of boric acid and SiO 2 The powder is mixed accord...

Embodiment 1

[0046] 1) First, soak ZTA in acetone for 20 minutes, pickle the ZTA particles, then clean them with acetone for 10 minutes by ultrasonic waves, wash them with deionized water, and dry the treated ZTA particles in a vacuum drying oven;

[0047] 2) Secondly, the dried ZTA and 4.7mm SiO 2 Put the small particles into a 75r / min planetary ball mill for 20 minutes of low-speed ball milling, and then filter the ZTA particles with a 10-mesh sieve;

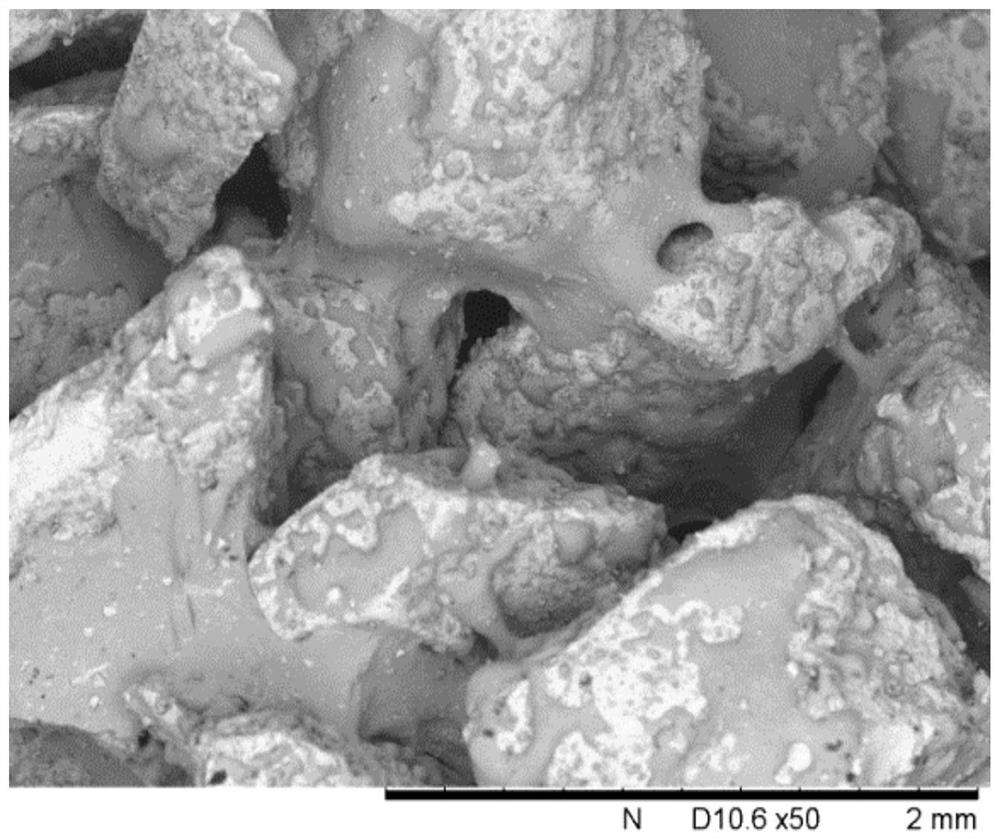

[0048] 3) Subsequently, wet mix NiCrAlY powder with absolute ethanol to obtain mixed powder. The mass ratio of NiCrAlY powder to absolute ethanol is 16:1, and the binder is made of boric acid and SiO 2 The powder is mixed at a mass ratio of 1:8, 4ml of binder is added to every 100g of ZTA mixture, the mass percentage of NiCrAlY powder and ZTA particles is 15%, the mixed ZTA particles are poured into a honeycomb mold and dried in vacuum

[0049] 4) Heating the honeycomb mold in a low-temperature heat treatment furnace for curing and shapin...

Embodiment 2

[0054] 1) First, soak ZTA in acetone for 25 minutes, pickle the ZTA particles, then clean them with acetone for 10 minutes by ultrasonic waves, wash them with deionized water, and dry the treated ZTA particles in a vacuum drying oven;

[0055] 2) Secondly, the dried ZTA and 4.8mm SiO 2 Put the small particles into a 100r / min planetary ball mill for 20 minutes of low-speed ball milling, and then filter the ZTA particles with a 25-mesh sieve;

[0056] 3) Subsequently, wet mix NiCrAlY powder with absolute ethanol to obtain mixed powder. The mass ratio of NiCrAlY powder to absolute ethanol is 17:1, and the binder is made of boric acid and SiO 2 The powder is mixed at a mass ratio of 1:8, 4.5ml of binder is added to every 100g of ZTA mixture, the mass percentage of NiCrAlY powder and ZTA particles is 20%, the mixed ZTA particles are poured into a honeycomb mold and then vacuum-baked Dry

[0057] 4) Heat the honeycomb mold in a low-temperature heat treatment furnace to cure and sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com