Solid-liquid filled low-surface-energy smooth functional material and preparation method thereof

A low surface energy, functional material technology, applied in the direction of fireproof coatings, additive processing, paints containing biocide, etc., can solve the problems of uncontrollable lubricant content, poor mechanical properties of materials, and can not be used as coatings, etc., to achieve the preparation method Simple and easy to control, improve mechanical properties, and improve processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

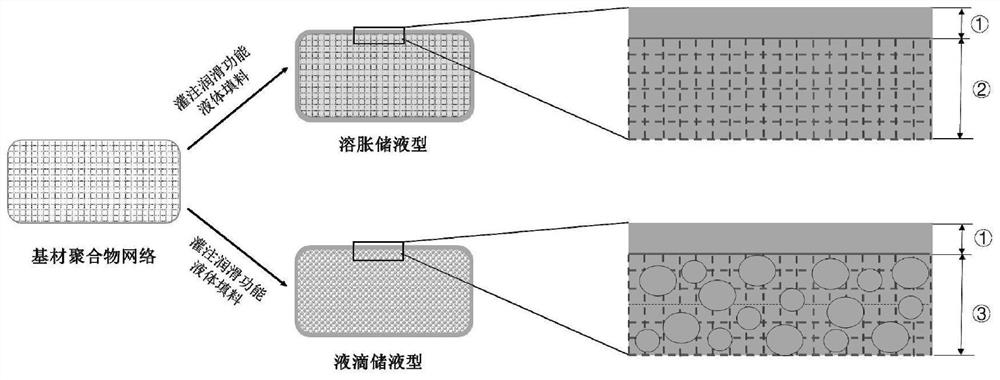

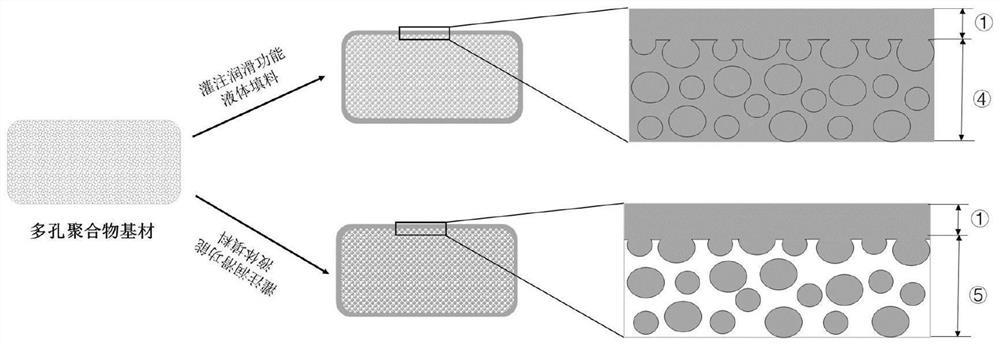

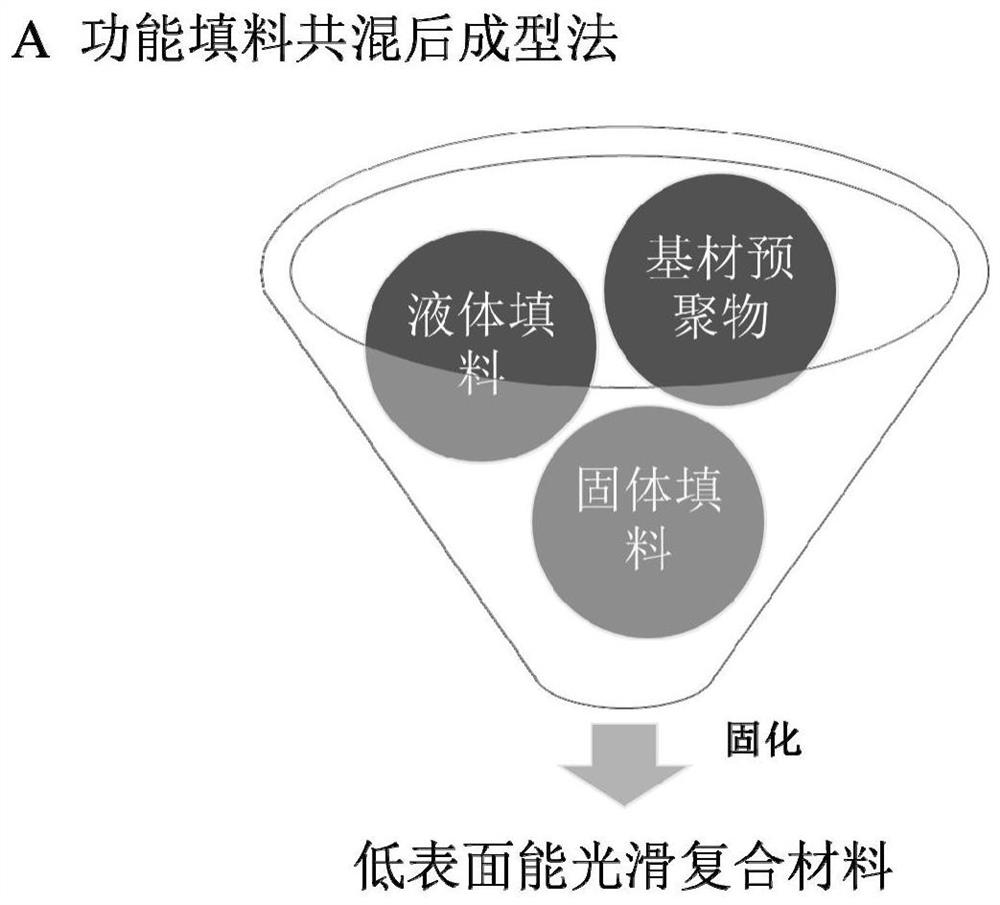

Method used

Image

Examples

Embodiment 1

[0048] A kind of base material that end-capping of large end group, its preparation method comprises the following steps:

[0049] Dissolve 2g of dimethylhydrogen-terminated dimethylsiloxane and 2g of monovinyl-terminated polysiloxane with a molecular weight of 2000 in toluene and stir. After mixing evenly, add a certain amount of Pt catalyst. Reaction 1d, and then carry out vacuum distillation and vacuum drying to remove the toluene solution to obtain vinyl-terminated polysiloxane. Mix the obtained vinyl-terminated polysiloxane with the fluorinated oligomeric silsesquioxane according to a molar ratio of 2:1 by mass, configure it into a 20wt% tetrahydrofuran solution, and then add a certain amount of Pt catalyst to mix and stir After 1 hour, the mixed solution was added dropwise into a polytetrafluoroethylene mold, and the organic reagent was removed to obtain a branched silicone substrate.

[0050] The branched silicone substrate prepared in this example has good transparenc...

Embodiment 2

[0052] A kind of supramolecular substrate containing dynamic bond, its preparation method comprises the following steps:

[0053] Dissolve the silicone containing diamino active group-terminated in an organic solvent and configure it into a linear silicone solution of 0.1-0.2mol / ml, and dissolve the diisocyanate active small molecules in an organic solvent and configure it into a 0.4-0.6mol / ml ml active small molecule solution, and then mixed according to the volume ratio of 10:2-4, then stirred at room temperature for 20-28h, and copolymerized to obtain a silicone solution. Add the organosilicon solution dropwise to the inorganic substrate, and volatilize in the air at room temperature for 4-6 days, because the supramolecular polymer network coating crosslinked by hydrogen bonds (linear organosilicon containing dynamic hydrogen bonds) is prepared by solvent volatilization , the gelation process of the polymer network cross-linked by hydrogen bonds is similar to the general fr...

Embodiment 3

[0056] A kind of porous base material preparation with water as porogen, its preparation method comprises the following steps:

[0057] Mix the two-component PDMS (Shenzhen Hongyejie E-6205) uniformly according to the mass ratio of 10:1 to obtain the organosilicon precursor, mix and stir 5g of the organosilicon precursor and 3g of water for 10min, add to the above emulsion After the Pt catalyst is mixed evenly, the obtained emulsion is poured on the substrate and pre-cured at room temperature for 30 minutes to obtain an opaque film material. The film material is placed at room temperature for 7 days, and the film changes from white opaque to transparent, and a transparent reversible Dynamic cellular elastomeric polymer materials.

[0058] The porosity of the porous elastomer base material obtained in this example is 83%, and the pore diameter range is 200-600 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com