Hard carbon-silicon carbon composite material, preparation method thereof and lithium ion battery

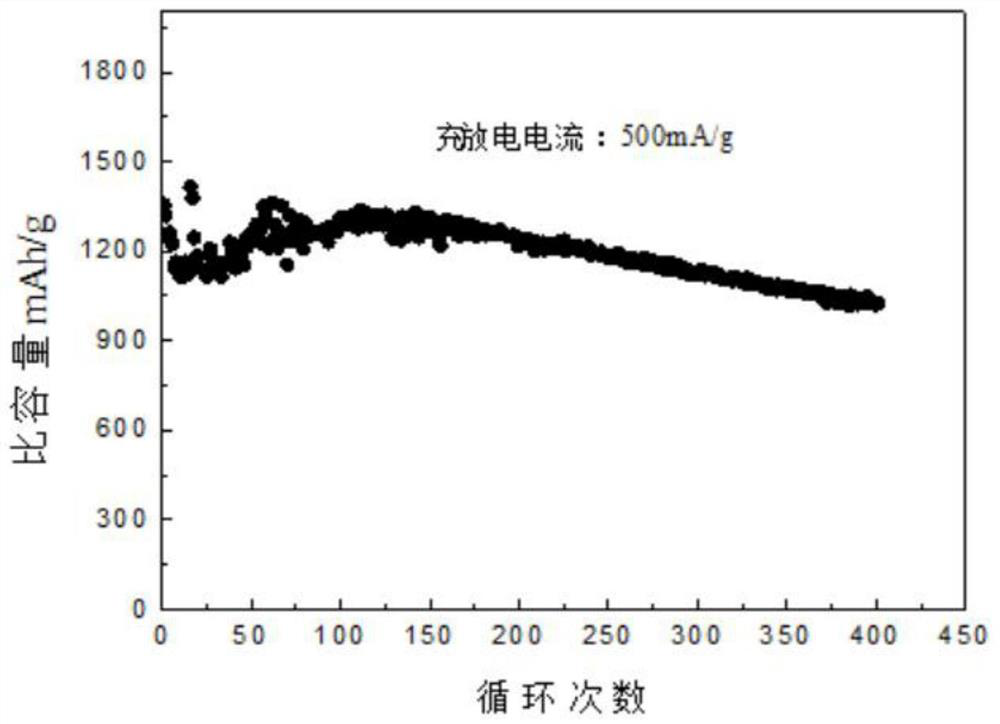

A silicon-carbon composite material and hard carbon technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as insufficient electrolyte, inability to eliminate charging expansion, large expansion degree, etc., achieve no memory effect, and improve adhesion Effect of impregnation and high working voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

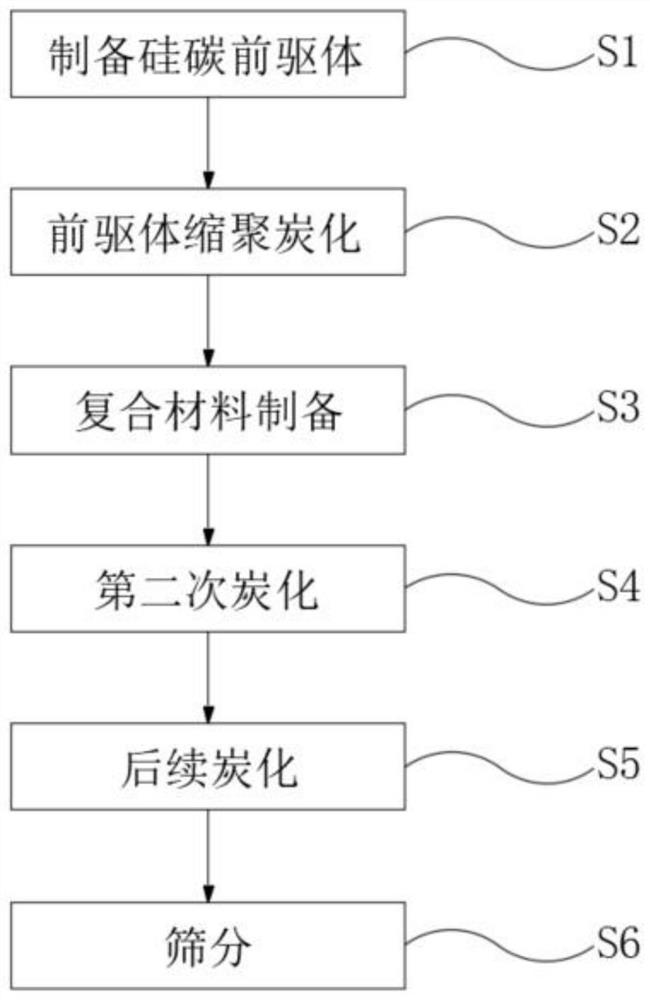

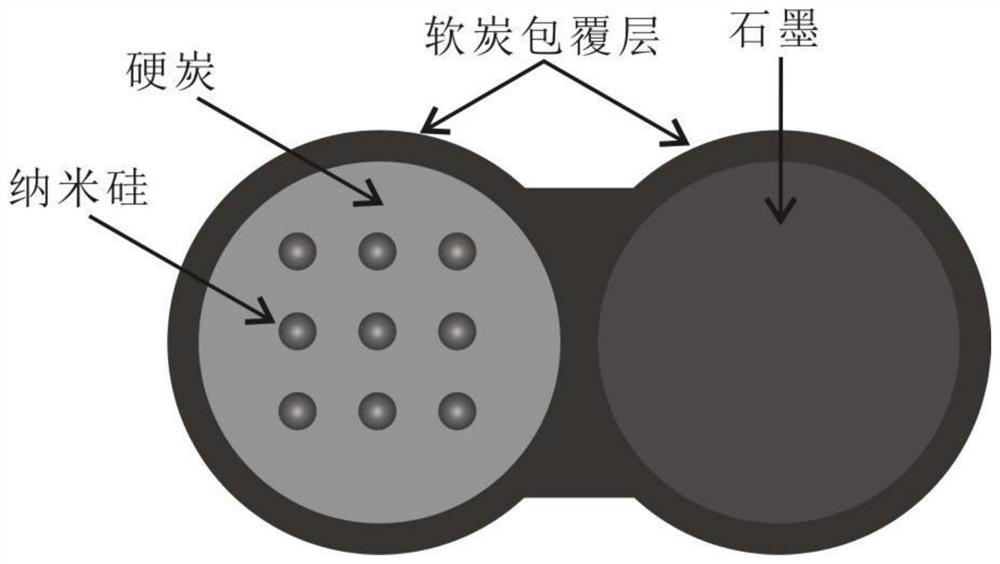

[0039] In order to prepare a hard carbon-silicon-carbon composite material with low expansion, high service life and high capacity, the present invention provides a method for preparing a hard carbon-silicon-carbon composite material, comprising the following steps:

[0040] Step S1, preparation of silicon carbon precursor: dissolving the soluble polymer material and dispersant in a solvent to form a mixed solution A, adding nano-silicon into the mixed solution A, dispersing to form a suspension B, and removing it under an inert atmosphere Solvent to obtain secondary structure nano silicon-soluble polymer material mixture powder C;

[0041]In this step, the particle size range of nano-silicon is in the range of 0.1-100nm, preferably in the range of 10-30nm, preferably, the mass ratio of the mass of nano-silicon to the suspension B is in the range of 0.5-20%, preferably The ground is within the range of 3 to 10%;

[0042] In this step, the soluble polymer material includes one...

Embodiment approach

[0080] The separator includes one or more combinations of polypropylene microporous membrane (PP), polyethylene microporous membrane (PE), glass fiber mat or PP / PE / PP. As a preferred implementation method, the separator is PP / PE / PP.

[0081] The positive electrode includes one or more of ternary materials, lithium iron phosphate, lithium manganese oxide and lithium cobalt oxide.

[0082] The electrolyte contains a lithium salt and a non-aqueous solvent, and the lithium salt can be lithium hexafluorophosphate, lithium tetrafluoroborate, lithium hexafluoroarsenate, lithium perchlorate, lithium trifluoromethanesulfonate, perfluorobutylsulfonic acid One or more combinations of lithium, lithium aluminate, lithium chloroaluminate, lithium fluorosulfonyl imide, lithium chloride and lithium iodide; the non-aqueous solvent can be γ-butyrolactone, methyl carbonate Ethyl ester, methyl propyl carbonate, dipropyl carbonate, acid anhydride, N-methylformamide, N-methylacetamide, acetonitril...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com