Edible fruit and vegetable nano coating preservative as well as preparation method and application thereof

A coating film preservative, nanotechnology, applied in the field of materials, can solve the problems of weak antibacterial performance, failure of antibacterial components, and no durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

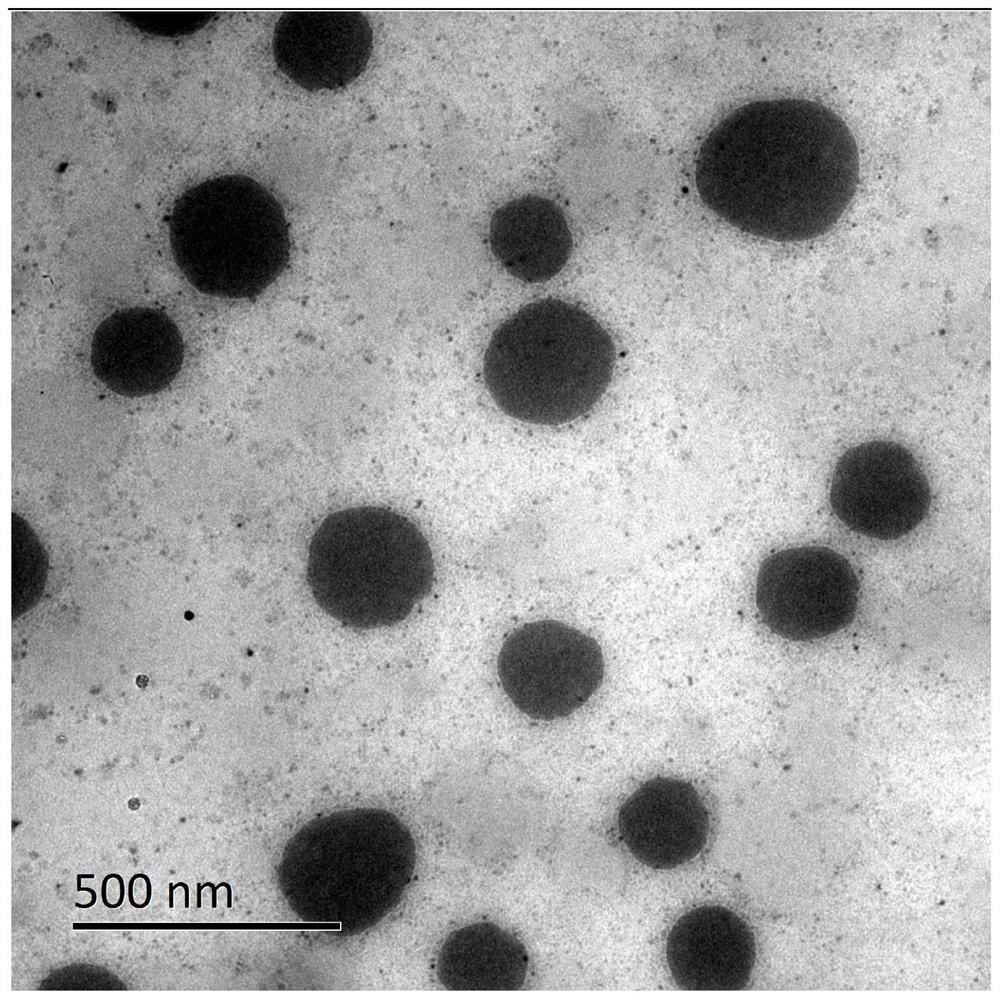

Image

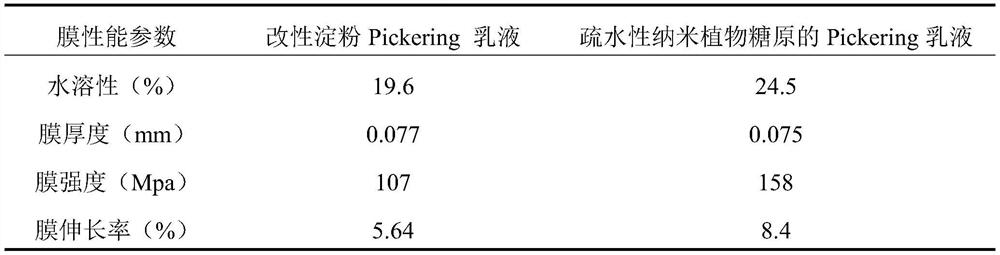

Examples

Embodiment 1

[0040] The preparation process of water-soluble nano plant glycogen suspension:

[0041] Weigh sweet corn seeds, add deionized water, and soak at 4°C for 24 hours. Remove the aqueous solution, pulverize with a mill, add deionized water according to the material-to-water ratio of 1:3 (v / v), and let stand at 4°C for 24 hours; take the supernatant, add acetic acid to adjust the pH to 4.8-5, and then set Let stand at 4°C for 24h; centrifuge at 3000g for 10 minutes to remove precipitation, and get the supernatant to boil in a boiling water bath, and centrifuge at 3000g for 10 minutes to further remove protein until there is no oil and no precipitation; add the obtained supernatant to absolute ethanol and stir Mix the supernatant and absolute ethanol in a volume ratio of 1:1, and let it stand at 4℃ until the precipitation is complete. After 3000g centrifugation, the precipitate is freeze-dried (temperature -55℃, vacuum degree 0.026mbar) to obtain water-soluble nano plant sugar origina...

Embodiment 2

[0048] Food-derived antimicrobial peptide Enterolysin A preparation process:

[0049] 1. Extract DNA from stinky tofu samples with DNA kit.

[0050] 2. Amplification of Enterolysin A gene: Use the obtained corresponding primers to amplify the Enterolysin A gene in stinky tofu using PCR technology.

[0051] 3. Cloning vector construction: After the PCR product is purified by agarose electrophoresis gel tapping, it is connected to the cloning vector pGM-T at 16°C overnight according to the molar ratio of the target fragment to the vector of 3:1. After the ligation, transfer the ligation product to E. coli TOP10 competent cells, and then spread it on the LB(Amp+) plate (1h in advance, spread 16μL of 50mg / mL IPTG, 40μL of 20mg / mL X-gal on the LB(Amp+) plate , Placed at 37°C) to form an Enterolysin A gene clone library. The next day, leukoplakia were picked and cultured overnight, and the recombinant clone plasmid pGM-T / Enterolysin A (plasmid extraction kit) was extracted.

[0052] 4. Ob...

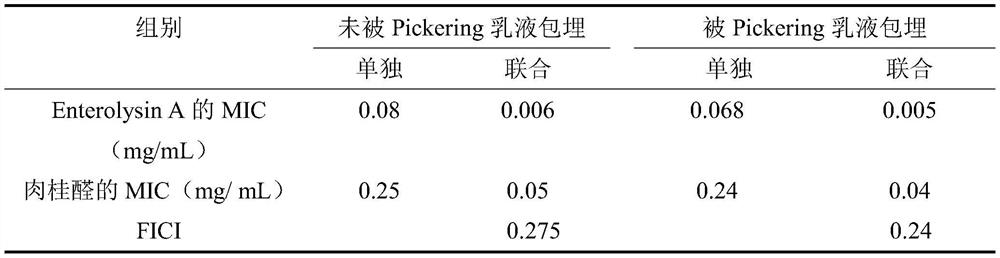

Embodiment 3

[0064] Preparation method of edible fruit and vegetable nano-coating antistaling agent:

[0065] The raw materials are calculated by mass percentage: 50wt% of Pickering emulsion of hydrophobic nano-plant glycogen; 0.5wt% of antibacterial peptide Enterolysin A; 2wt% of cinnamaldehyde; 5wt% of chitosan; 3wt% of sorbitol; 39.5wt% of deionized water.

[0066] Take the film-forming agent chitosan and the plasticizer sorbitol and dissolve them in deionized water, heat at 70°C for 10 minutes, and stir at a slight uniform speed during the heating to prevent the generation of bubbles and the denaturation of chitosan. After heating, cool to room temperature for later use.

[0067] Take Pickering emulsion and add the antimicrobial peptide Enterolysin A and cinnamaldehyde, mix well and set aside.

[0068] Mix the above two solutions 1:1 and stir evenly to obtain the edible nanometer fruit and vegetable coating preservative.

[0069] Take 20mL of the edible fruit and vegetable nano-coating antistali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com