Battery-grade ferric orthophosphate as well as preparation method and application thereof

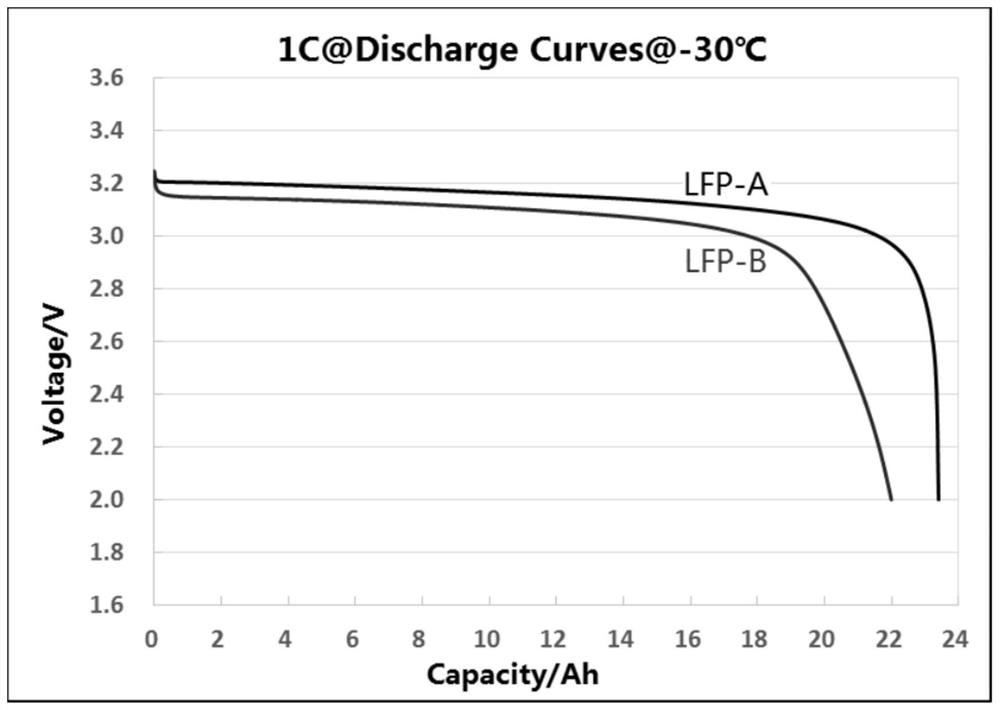

An iron orthophosphate, battery-level technology, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve the problems of poor low-temperature performance, unclear crystal structure, and disjointed preparation of lithium iron phosphate, and achieve good fluidity and packaging The effect of excellent coating effect and excellent low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A battery grade ferric orthophosphate, which is prepared as follows:

[0028] S1, in the kettle that is equipped with 2.2mol / L ferrous sulfate solution and is continuously stirred at a frequency of 75Hz, a peristaltic pump is used to add a concentration of 80% phosphoric acid solution at a flow rate of 50L / h. After the addition, stir for 3.5h, and then Use a peristaltic pump to inject 22% ammonia water at a flow rate of 110L / h and adjust the pH value of the reaction solution to 2.2, control the temperature of the reaction system to 80°C, and then use a gas flow meter to 3 The flow rate / h added concentration is 2.5×10 5 ppm ozone, finally add flocculant ferric sulfate, after complete addition, stir for 3.5h, and let stand for 1.2h after stirring.

[0029] S2, then press-filter and wash the reaction product in S1 to obtain ferric phosphate dihydrate;

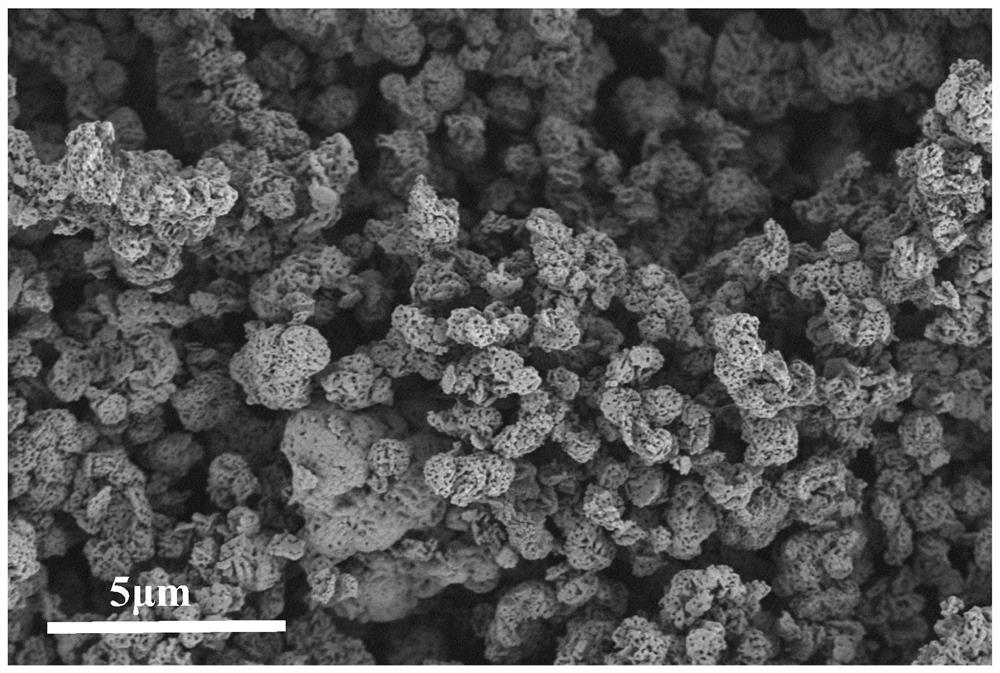

[0030] S3. Physicochemically granulate ferric phosphate dihydrate, calcining at 620° C. for 4.5 hours to obtain anhydro...

Embodiment 2

[0035] A battery grade ferric orthophosphate, which is prepared as follows:

[0036] S1. Use a peristaltic pump to add a phosphoric acid solution with a concentration of 75% at a flow rate of 40L / h to the kettle equipped with 2mol / L ferrous sulfate solution and continuously stirred at a frequency of 70Hz. After the addition, stir for 3h, and then use peristaltic The pump injects 20% sodium hydroxide at a flow rate of 100L / h and adjusts the pH value of the reaction solution to 2.0, controls the temperature of the reaction system to be 75°C, and then uses a gas flow meter to 3 The flow rate / h added concentration is 2×10 5 ppm ozone, finally add the flocculant ferric chloride, stir for 3 hours after complete addition, and let stand for 1 hour after stirring.

[0037] S2, then press-filter and wash the reaction product in S1 to obtain ferric phosphate dihydrate;

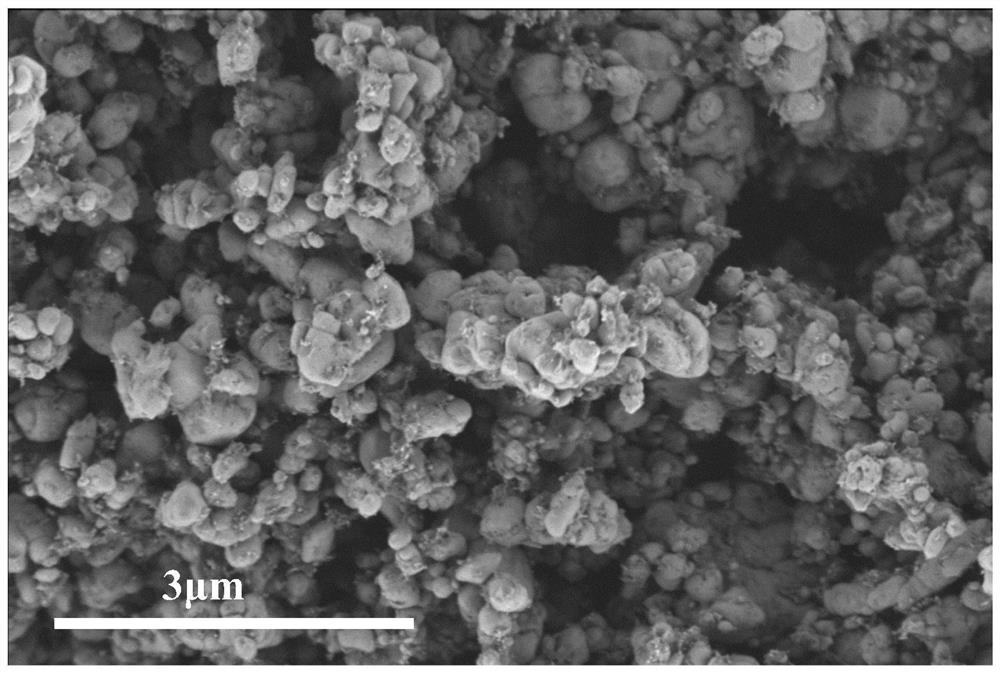

[0038] S3. Physicochemically granulate ferric phosphate dihydrate, calcining at 600° C. for 4 hours to obtain anhydr...

Embodiment 3

[0041] A battery grade ferric orthophosphate, which is prepared as follows:

[0042]S1. Use a peristaltic pump to add a phosphoric acid solution with a concentration of 85% at a flow rate of 60L / h into a kettle equipped with a 2.5mol / L ferrous sulfate solution and continuously stirred at a frequency of 80Hz. After the addition, stir for 4h, and then use The peristaltic pump injects 25% sodium hydroxide with a flow rate of 120L / h and adjusts the pH value of the reaction solution to 2.5, controls the temperature of the reaction system to be 85°C, and then uses a gas flow meter to 3 The flow rate / h added concentration is 3×10 5 ppm ozone, finally add flocculant ferric sulfate, after complete addition, stir for 4 hours, and let stand for 1.5 hours after stirring.

[0043] S2, then press-filter and wash the reaction product in S1 to obtain ferric phosphate dihydrate;

[0044] S3. Physicochemically granulate ferric phosphate dihydrate, calcining at 650° C. for 5 hours to obtain an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com