High-thermal-shock-resistance and long-service-life sagger and preparation method

A long-life, saggar technology, applied in lighting and heating equipment, furnace components, furnaces, etc., can solve problems such as poor thermal shock resistance, weak refractoriness and high temperature resistance, and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

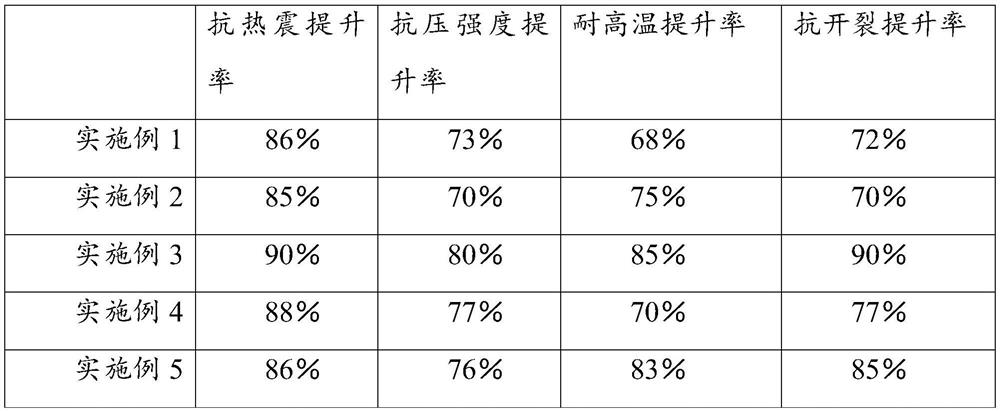

Examples

Embodiment 1

[0030] The present invention provides a high heat shock long life sagger:

[0031] The materials used include the following raw materials in parts by weight: 100 parts of silicon carbide, 52 parts of mullite, 28 parts of spinel, 9 parts of graphite, 26 parts of zirconia, 11 parts of steel fiber, 8 parts of magnesium oxide, Calcium 4 parts, aluminum alloy 5 parts.

[0032] A method for preparing a high thermal shock and long-life sagger, the processing steps are as follows:

[0033] Step 1. Preparation of raw materials. Silicon carbide and mullite are used as basic raw materials, and spinel, graphite, zirconia, steel fiber, magnesium oxide, calcium oxide, and aluminum alloy are used as auxiliary materials;

[0034] Step 2. Raw materials are pre-fired. The raw materials in step 1 are pre-fired respectively. The pre-burning temperature is 90°C, and the pre-burning time is 2 hours;

[0035] Step 3, raw material is crushed, and the raw material after the raw material preburning i...

Embodiment 2

[0044] The present invention provides a high heat shock long life sagger:

[0045]The materials used include the following raw materials in parts by weight: 110 parts of silicon carbide, 54 parts of mullite, 28 parts of spinel, 9 parts of graphite, 26 parts of zirconia, 11 parts of steel fiber, 8 parts of magnesium oxide, Calcium 4 parts, aluminum alloy 5 parts.

[0046] A method for preparing a high thermal shock and long-life sagger, the processing steps are as follows:

[0047] Step 1. Preparation of raw materials. Silicon carbide and mullite are used as basic raw materials, and spinel, graphite, zirconia, steel fiber, magnesium oxide, calcium oxide, and aluminum alloy are used as auxiliary materials;

[0048] Step 2. Raw materials are pre-fired. The raw materials in step 1 are pre-fired respectively. The pre-burning temperature is 90°C, and the pre-burning time is 2 hours;

[0049] Step 3, raw material is crushed, and the raw material after the raw material preburning in...

Embodiment 3

[0058] The present invention provides a high heat shock long life sagger:

[0059] The materials used include the following raw materials in parts by weight: 120 parts of silicon carbide, 56 parts of mullite, 28 parts of spinel, 9 parts of graphite, 26 parts of zirconia, 11 parts of steel fiber, 8 parts of magnesium oxide, Calcium 4 parts, aluminum alloy 5 parts.

[0060] A method for preparing a high thermal shock and long-life sagger, the processing steps are as follows:

[0061] Step 1. Preparation of raw materials. Silicon carbide and mullite are used as basic raw materials, and spinel, graphite, zirconia, steel fiber, magnesium oxide, calcium oxide, and aluminum alloy are used as auxiliary materials;

[0062] Step 2. Raw materials are pre-fired. The raw materials in step 1 are pre-fired respectively. The pre-burning temperature is 90°C, and the pre-burning time is 2 hours;

[0063] Step 3, raw material is crushed, and the raw material after the raw material preburning i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com