A light, simple and high-efficiency cultivation method of flue-cured tobacco without film and upper box

A cultivation method and flue-cured tobacco technology are applied in the field of crop cultivation and flue-cured tobacco planting and cultivation, which can solve the problems of low planting benefit, low yield of tobacco leaves and high planting cost, and achieve the effects of promoting sustainable development, balancing inorganic nutrients and reducing fertilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

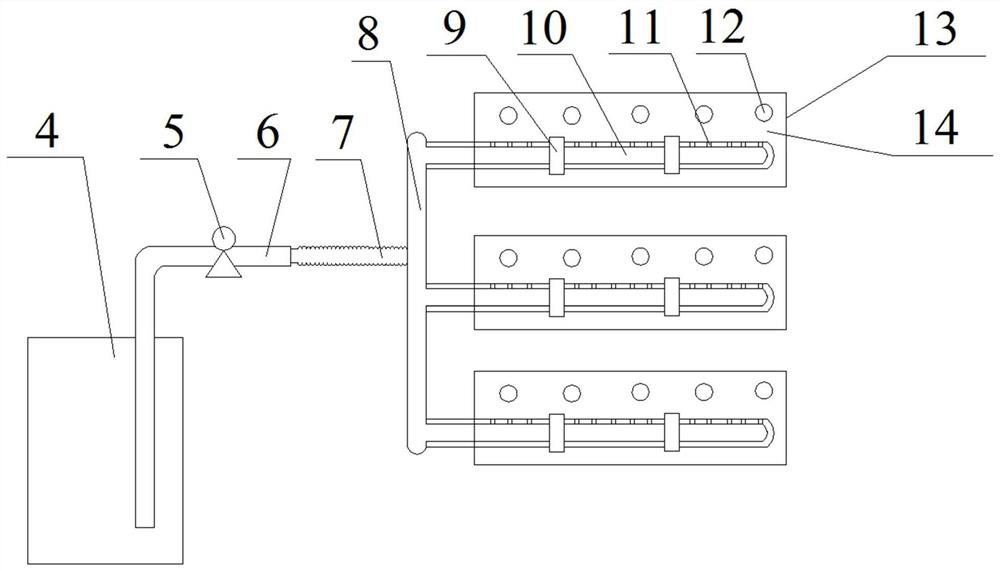

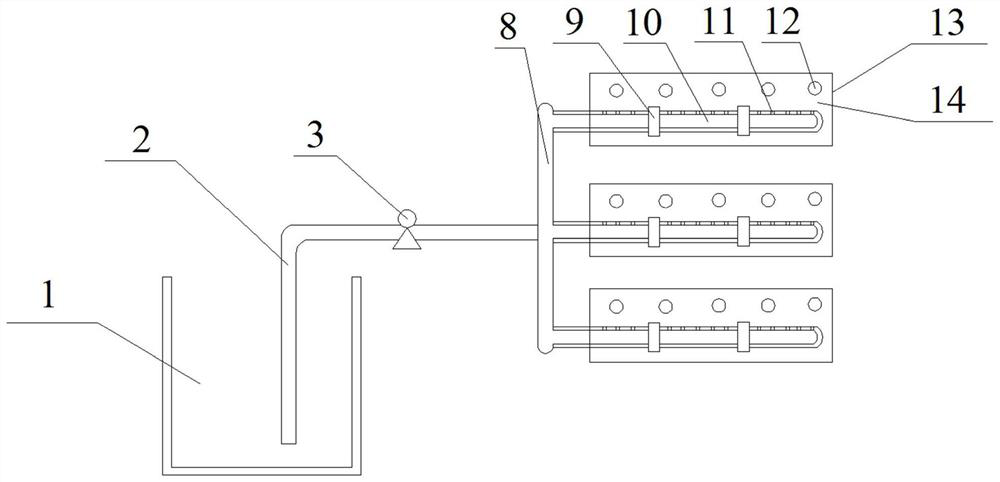

[0057] Such as figure 1 As shown, a flue-cured tobacco-free film is light and efficient cultivation method, including the following steps:

[0058] Step 1, planting the ridge 13 and form a plurality of ridges 13;

[0059] Step 2, fertilizing, fertilizing in each ridge 13, plasma organic fertilizer and particle organic inorganic compound fertilizer, fertilizing, fertilizing, lap, is a circular fertilizer from 5-7cm from the smoke seedling , The strip is to fertilize 5-8 stumps from the side or both sides of the smoke seedlings or both sides, and fertilizes the depth of 10-15 ㎝;

[0060] Step 3, mount the water spray system, the water spray system including a ridge 13 and a water spray system including a water supply mechanism located on the side of the ridge 13, communicating with the water supply mechanism and in the ridge 13 The sprinkler 10 of the upper portion is located on the spray tube 10 on the spray tube 10 and the ground film 14 on the upper portion of the sprinkler 10, t...

Embodiment 2

[0065] On the basis of Example 1, the primary sexy fertilizer 60-80 kg per mu is applied in step 2, and the particle organic inorganic compound fertilizer is 70-90 kg per mu.

Embodiment 3

[0067] Based on the basis of Example 2, the preparation method of the particulate organic fertilizer, including the steps of:

[0068] a, mix all the raw materials machinery and adjust the water content of 55-65%, each raw material is measured by weight, including 50-50 parts of the slag, 20-30 oil, 20-30 dry cow feces, straw 10-20 powder, 1-2 urea, 0.2-0.5 by fermentation;

[0069] b, in a tank fermentation tank with ventilation and pumping devices for 10-20 days, the fermentation is automatically filled with 3-5 times during fermentation;

[0070] C. The material after fermentation is dried, cooled, pulverized, and the sieve is made into a fineness of 30-60 for the organic material;

[0071]D, add an ammonium phosphate, potassium sulfate, amino acid, humic acid, magnesium sulfate, zinc sulfate, boric acid, bentonite granulation, granulation materials, 70-80 parts by weight, organic material, an ammonium phosphate 2.5-5 Part, 5-10 sulfate, 2.5-5 amino acids, 2.5-5 hydrocyanic aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com