Preparation method for anti-ultraviolet-ray anti-yellowing waterproof coating fabric

A waterproof coating and anti-ultraviolet technology, applied in the field of textile processing, can solve the problems of polyurethane materials such as the decline in physical and mechanical properties, anti-ultraviolet, poor weather resistance, low strength, etc., achieve excellent anti-ultraviolet function, keep the appearance beautiful, and prolong the service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

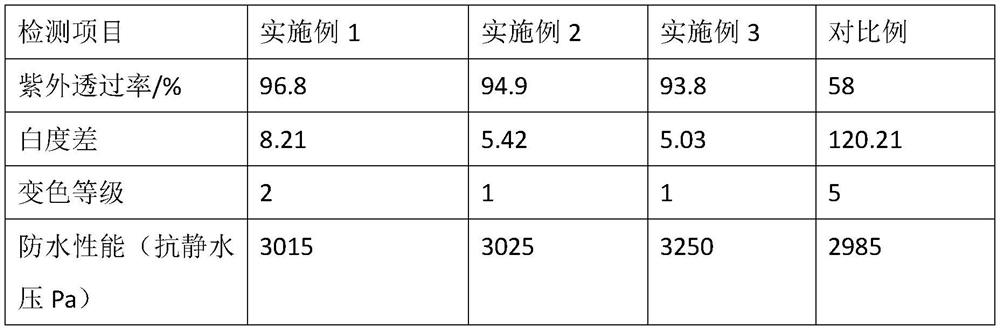

Examples

Embodiment 1

[0028] A preparation method for an anti-ultraviolet and anti-yellowing waterproof coating fabric, comprising the steps of:

[0029] (1) Add the ultraviolet shielding agent into the water, stir evenly, prepare the dispersion liquid of the ultraviolet shielding finishing agent with a mass concentration of 15%, place it in the trough of the padding machine, and process the polyester base cloth with two dipping and two rolling processes at room temperature, and roll The remaining rate is 60%. After baking at 120°C for 20s, calendering treatment is carried out to obtain the treated fabric;

[0030] (2) 0.5 part of organic UV absorber (2-hydroxy-4-n-octyloxybenzophenone), 0.2 part of antioxidant (tetrakis[β-(3,5-di-tert-butyl-4-hydroxy phenyl) propionate] pentaerythritol ester) and 0.2 parts of light stabilizer (polymer of succinic acid and 4-hydroxy-2,2,6,6-tetramethyl-1-piperidinol) added to 31.53 parts of organic After dissolving in the solvent (toluene), add 0.05 parts of UV sh...

Embodiment 2

[0034] A preparation method for an anti-ultraviolet and anti-yellowing waterproof coating fabric, comprising the steps of:

[0035] (1) Add the ultraviolet shielding agent into the water, stir evenly, prepare the dispersion liquid of the ultraviolet shielding finishing agent with a mass concentration of 15%, place it in the trough of the padding machine, and process the polyester base cloth with two dipping and two rolling processes at room temperature, and roll The remaining rate is 70%. Calendering treatment is performed after baking at 135°C for 25s to obtain the treated fabric;

[0036] (2) Mix 1 part of organic UV absorber (2-hydroxy-4-n-octyloxybenzophenone), 0.5 part of antioxidant (tetrakis[β-(3,5-di-tert-butyl-4-hydroxy Phenyl) propionic acid] pentaerythritol ester) and 0.5 parts of light stabilizer (polymer of succinic acid and 4-hydroxy-2,2,6,6-tetramethyl-1-piperidinol) added to 22.9 parts of organic After dissolving in the solvent (butanone), add 0.1 part of UV s...

Embodiment 3

[0040] A preparation method for an anti-ultraviolet and anti-yellowing waterproof coating fabric, comprising the steps of:

[0041] (1) Add the ultraviolet shielding agent into the water, stir evenly, prepare the dispersion liquid of the ultraviolet shielding finishing agent with a mass concentration of 15%, place it in the trough of the padding machine, and process the polyester base cloth with two dipping and two rolling processes at room temperature, and roll The remaining rate is 80%, and calendering treatment is performed after baking at 150°C for 30s to obtain the treated fabric;

[0042](2) 2.5 parts of organic UV absorber (2-(2'-hydroxy-3'-tert-butyl-5'-methylphenyl)-5-chlorobenzotriazole), 1.5 parts of antioxidant (Distearyl thiodipropionate) and 1.5 parts of light stabilizer (bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate) were added to 11.5 parts of organic solvent After dissolving in (butanone), add 0.8 parts of UV shielding agent, and after mixing, add 82 parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com