Binder composition for electrode of secondary battery, and electrode mixture

A secondary battery and adhesive technology, applied in secondary batteries, battery electrodes, non-aqueous electrolyte battery electrodes, etc., can solve the problems of accelerated swelling and reduced battery stability, and achieve improved performance and excellent adhesion. Strength, effect of excellent latex stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0090] Simultaneously, according to another aspect of the present invention, a kind of preparation method of the adhesive composition for secondary battery electrode is provided, and this preparation method comprises the following steps:

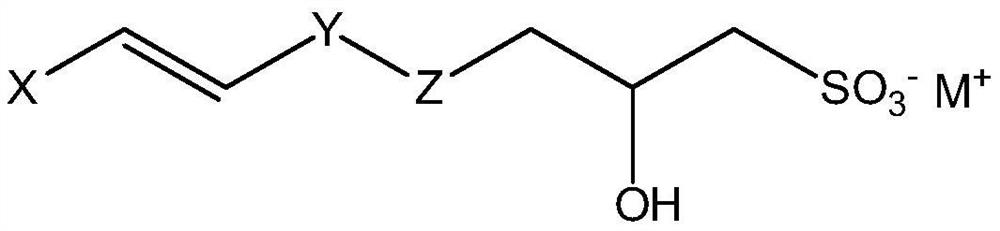

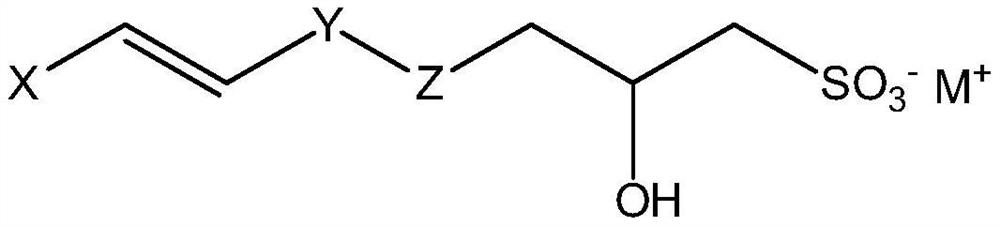

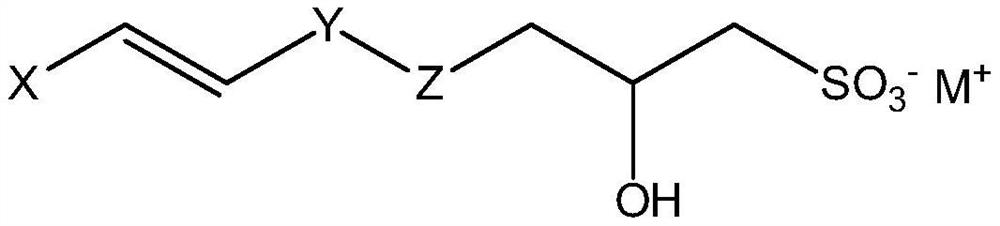

[0091] In the presence of an emulsifier and a polymerization initiator, the aliphatic conjugated diene-based first monomer; selected from aromatic vinyl-based monomers, alkyl (meth)acrylate monomers, (meth)acrylic monomers One or more second monomers in amide monomers, alkenyl cyanide monomers and unsaturated carboxylic acid monomers; and the third monomer represented by Chemical Formula 1 is emulsion polymerized to prepare the copolymer,

[0092] Wherein, relative to the total amount of the first monomer, the second monomer and the third monomer, the amount of the third monomer is 0.5% to 0.95% by weight.

[0093] In this respect, the first monomer, the second monomer and the third monomer are the same as described above.

[0094] In addit...

Embodiment 1

[0139] (1) Preparation of adhesive

[0140] (a) 1,3-butadiene (44 g), (b1) styrene (47.05 g), (b2) methyl methacrylate (5 g), (b5) acrylic acid and itaconic acid ( 3g) and (c) sodium 3-allyloxy-2-hydroxypropylsulfonate (0.95g), and sodium lauryl sulfate and polyethylene oxide lauryl ether (1.3g) as emulsifiers were added to Contains NaHCO 3 water as a buffer, and the temperature was raised to 75°C, and then ammonium persulfate was added as a polymerization initiator to perform single polymerization. The reaction was carried out for about 8 hours while maintaining the temperature at 75° C., thereby preparing an adhesive composition including the copolymer in the form of latex particles. The adhesive composition of Example 1 thus prepared had a total solid content of 40%, and an average particle diameter of latex particles measured using a particle size analyzer (NICOMP AW380, manufactured by PSS) was 110 nm. The pH of the fully polymerized adhesive composition was adjusted t...

Embodiment 2

[0146] (1) Preparation of adhesive

[0147] In addition to using (a) 1,3-butadiene (45 g), (b1) styrene (46.3 g), (b2) methyl methacrylate (5 g), (b5) acrylic acid and itaconic acid (3 g) and (c) Except for 3-allyloxy-2-hydroxypropyl sodium sulfonate (0.7 g) as a monomer, polymerization was carried out in the same manner as in Example 1 to prepare a latex containing 111 nm in average particle diameter. Adhesive composition of copolymer in particulate form.

[0148] (2) Preparation of negative electrode mixture and manufacture of negative electrode

[0149] Using the binder of Example 2 instead of the binder of Example 1, an anode mixture was prepared in the same manner as in Example 1, and the anode mixture of Example 2 was manufactured using the anode mixture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com