Preparation method of magnetic molecularly imprinted polymer for adsorbing methylene blue

A technology of magnetic molecular imprinting and methylene blue, applied in alkali metal compounds, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of low adsorption capacity, slow adsorption speed, pollution, etc., achieve excellent adsorption capacity, and save business cost, environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of the magnetic molecularly imprinted polymer in this embodiment comprises the following steps:

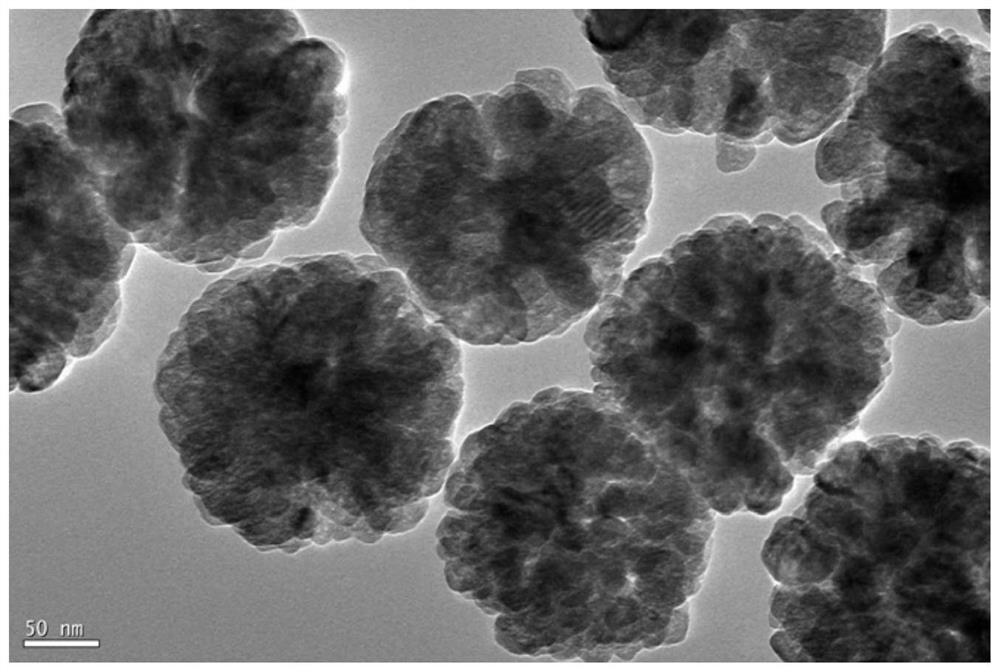

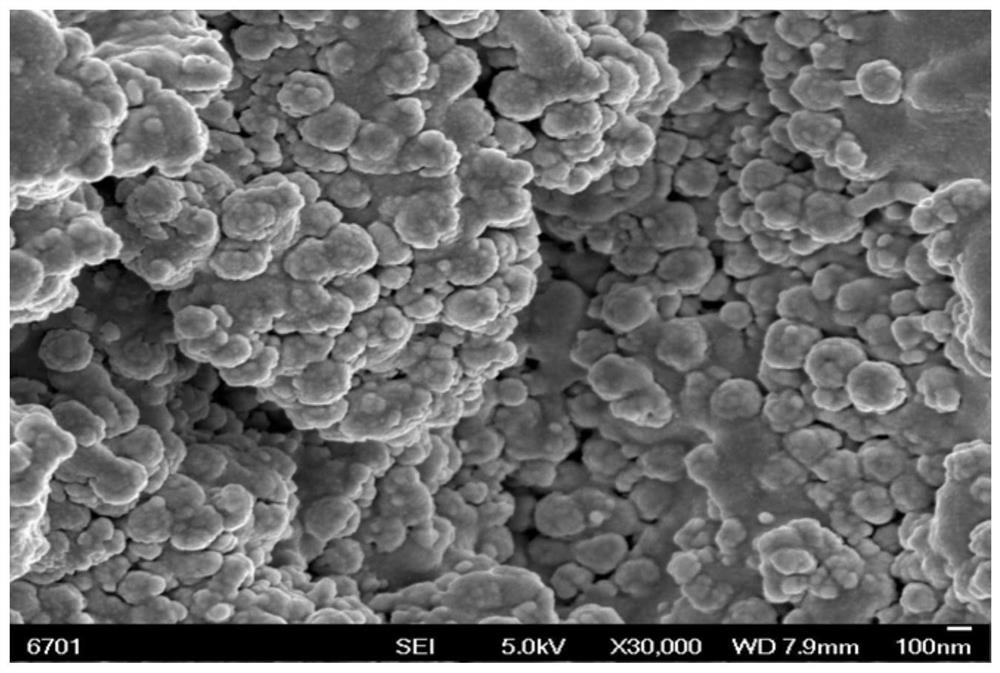

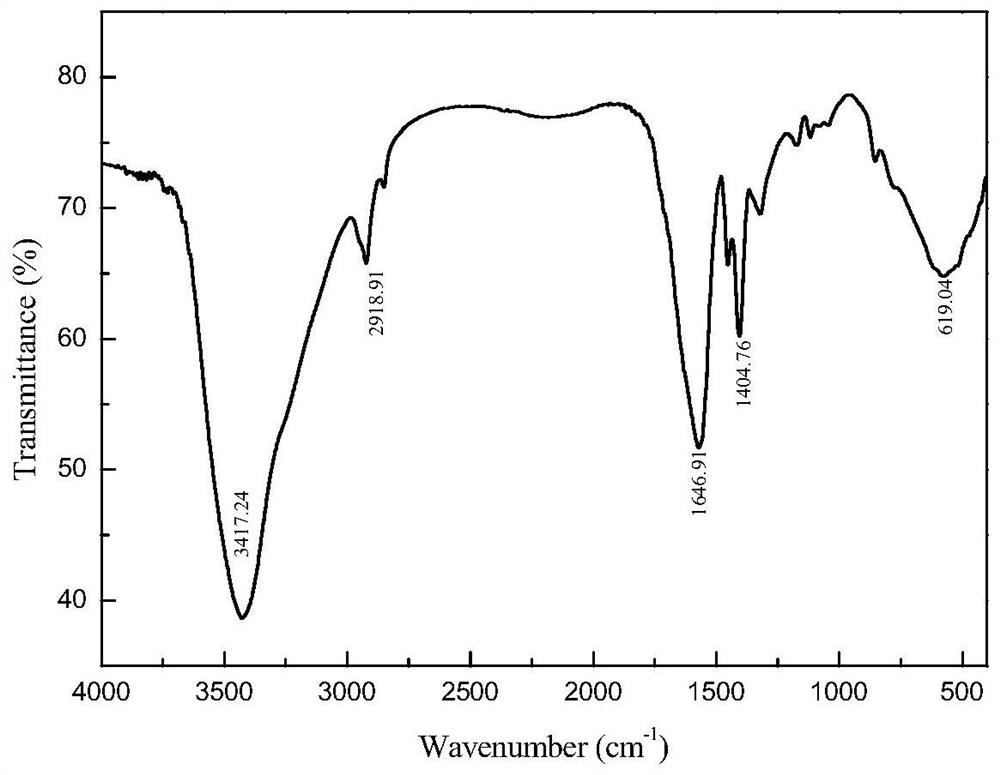

[0029] 1) Preparation of magnetic substances: Accurately measure 160mL of ethylene glycol in a conical flask, add 5.4g of FeCl 3 ·6H 2 O, sonicate until dissolved to obtain a yellow transparent liquid, sequentially add 14.4g of anhydrous sodium acetate and 4.0g of polyethylene glycol (2000) into the liquid, stir vigorously for half an hour, place it in a hydrothermal synthesis reactor, and seal the reactor , put it in a drying oven at 200°C for 8 hours, take it out, cool it down to room temperature naturally, pour off the upper oil phase clear liquid, and wash it with ethanol and distilled water for several times until the supernatant liquid is transparent, indicating that the reaction impurities have been removed. It was dried in a vacuum oven at 70°C for 12 hours to obtain black nano-Fe 3 o 4 Particles (such as figure 1 As shown, its particle si...

Embodiment 2

[0037] The preparation method of the magnetic molecularly imprinted polymer in this embodiment comprises the following steps:

[0038] 1) Preparation of magnetic substance: add 162ml ethylene glycol solution in a beaker, mix 5.5g FeCl 3 ·6H 2 O was added to the beaker and dissolved by ultrasonication for 30 min to obtain a yellow transparent oily solution. Add 15 g of anhydrous sodium acetate and 5 g of ground polyethylene glycol (2000) to the above solution, stir magnetically for 1.5 h, and ultrasonically dissolve for 30 min to form a uniform yellow oily emulsion. Add the dissolved emulsion into the hydrothermal synthesis reaction kettle, seal the reaction kettle, then put it in a dry box, react at 200°C for 8 hours, take out the reaction kettle and cool it at room temperature for a period of time, open the reaction kettle to observe Until the black particles gather and settle at the bottom of the reactor. Pour the upper waste liquid into the waste liquid bucket, and use d...

Embodiment 3

[0043] The preparation method of the magnetic molecularly imprinted polymer in this embodiment comprises the following steps:

[0044] 1) Preparation of magnetic substances: Accurately measure 160mL of ethylene glycol in a conical flask, add 5.4g of FeCl 3 ·6H 2 0, stirred until dissolved to obtain a yellow transparent liquid, sequentially added 14.4g sodium acetate and 4.0g polyethylene glycol (2000) into the liquid and placed in a hydrothermal synthesis reactor after vigorously stirring for half an hour, sealed the reactor, and put Put it into a drying oven at 200°C for 8 hours, take it out, cool it down to room temperature naturally, pour off the upper oil phase clear liquid, wash with ethanol and distilled water several times, until the supernatant liquid is transparent, indicating that the reaction impurities have been removed, put it away Dry in a vacuum oven at 70°C for 12 hours to obtain black nano-Fe 3 o 4 Granules for spare.

[0045] 2) Preparation of magnetic mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com