Chemical tin plating technology for crystalline silicon heterojunction solar cell

A technology for solar cells and electroless tin plating, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problems of weakened stability of electroless tin plating solution, turbidity of electroless tin plating solution, long time consumption, etc. , to achieve the effect of improving long-term stability, reasonable formula and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

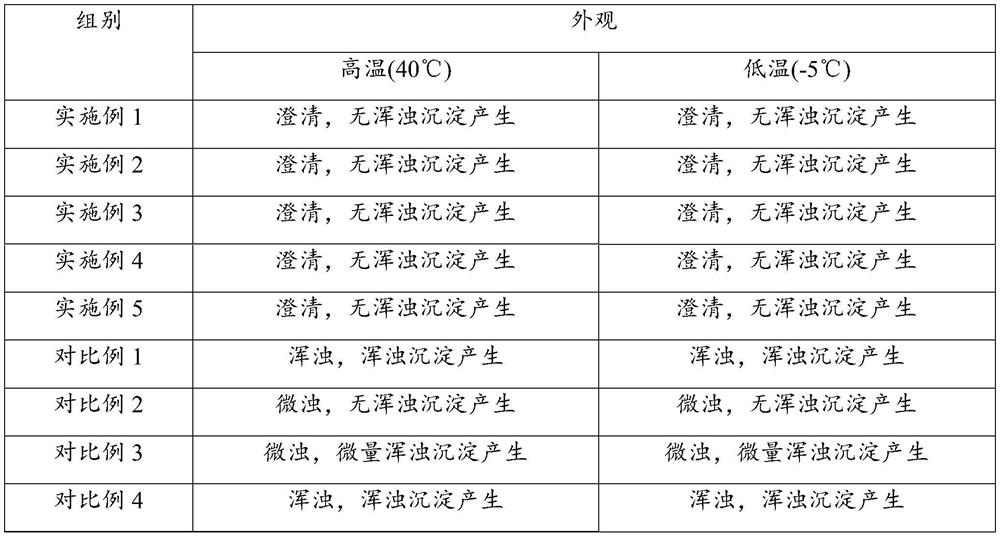

Examples

Embodiment 1

[0030] A kind of electroless tin plating solution, with deionized water as solvent, comprising the components of following concentrations: tin methanesulfonate 10g / L, sodium dodecylbenzenesulfonate 0.25g / L, naphthalene ethoxysulfonate Acid 0.1g / L, stachyose 0.05g / L, distyryl ketone 0.06g / L, alkylaniline 0.5g / L, sodium hypophosphite 25g / L, dimethylaminoborane 25g / L, Alkylphenol polyoxyethylene ether 0.357g / L and polyethylene glycol 0.143g / L.

[0031] A preparation method for electroless tin plating solution, comprising the following steps:

[0032] S1. Mix tin methanesulfonate, sodium dodecylbenzenesulfonate, naphthalene ethoxysulfonic acid, stachyose and deionized water in the formula to obtain mixture A;

[0033] S2. Mix distyryl ketone, alkylaniline, sodium hypophosphite, dimethylaminoborane, alkylphenol polyoxyethylene ether and polyethylene glycol in the formula to obtain mixture B;

[0034] S3. Add the mixture B in step S2 to the mixture A in step S1, after pumping for ...

Embodiment 2

[0037] A kind of electroless tin plating solution, take deionized water as solvent, comprise the component of following concentration: tin protochloride 15g / L, sodium dodecylbenzene sulfonate 0.35g / L, naphthol ethoxy sulfonic acid 0.15g / L, stachyose 0.1g / L, distyryl ketone 0.08g / L, thiadiazole 0.7g / L, sodium hypophosphite 35g / L, dimethylaminoborane 30g / L, alkane Base phenol polyoxyethylene ether 0.667g / L and polyethylene glycol 0.333g / L.

[0038] A preparation method for electroless tin plating solution, comprising the following steps:

[0039] S1. Mix stannous chloride, sodium dodecylbenzenesulfonate, naphthalene ethoxysulfonic acid, stachyose and deionized water in the formula to obtain mixture A;

[0040] S2. Mix distyryl ketone, thiadiazole, sodium hypophosphite, dimethylaminoborane, alkylphenol polyoxyethylene ether and polyethylene glycol in a formula amount to obtain a mixture B;

[0041]S3. Add the mixture B in step S2 to the mixture A in step S1, after pumping for 4...

Embodiment 3

[0044] A kind of electroless tin plating solution, take deionized water as solvent, comprise the component of following concentration: tin methanesulfonate 15g / L, sodium dodecylbenzenesulfonate 0.4g / L, naphthalene ethoxysulfonate Acid 0.2g / L, stachyose 0.15g / L, distyryl ketone 0.1g / L, alkylaniline 0.9g / L, sodium hypophosphite 40g / L, dimethylaminoborane 40g / alkyl Phenol polyoxyethylene ether 1.25g / L and polyethylene glycol 0.75g / L. L.

[0045] A preparation method for electroless tin plating solution, comprising the following steps:

[0046] S1. Mix tin methanesulfonate, sodium dodecylbenzenesulfonate, naphthalene ethoxysulfonic acid, stachyose and deionized water in the formula to obtain mixture A;

[0047] S2. Mix distyryl ketone, alkylaniline, sodium hypophosphite, dimethylaminoborane, alkylphenol polyoxyethylene ether and polyethylene glycol in the formula to obtain mixture B;

[0048] S3. Add the mixture B in step S2 to the mixture A in step S1, after pumping for 4-5min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com