PtCo@N-GNS catalyst and preparation method and application thereof

A catalyst and solvent technology, applied in the field of PtCo@N-GNS catalyst and its preparation, can solve the problems of large-scale application limitations of Pt/C, and achieve high-scale production value, good catalytic activity, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

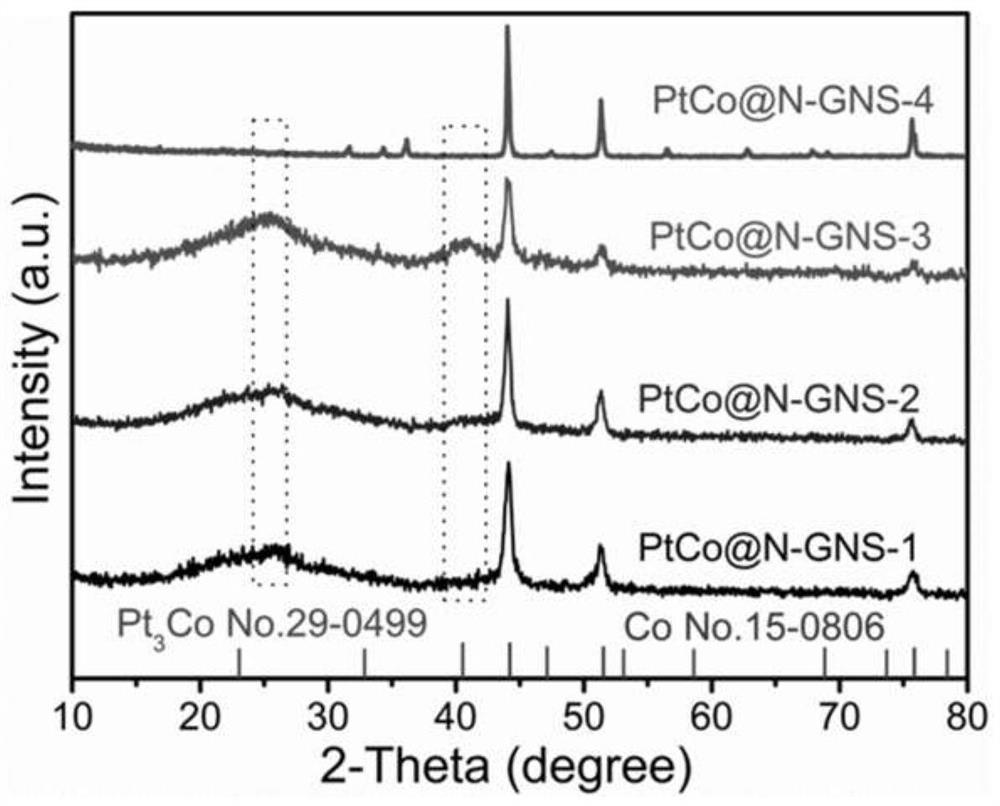

[0032] The invention provides a method for preparing a low-platinum-loaded PtCo@N-GNS bifunctional catalyst, comprising the following steps:

[0033] Step 1. Synthesize zeolite imidazolate framework material ZIF-8, disperse zinc nitrate hexahydrate and 2-methylimidazole in methanol, the molar ratio of metal salt and ligand is 1:4, the reaction time is 24h, and the stirring speed is 500 rpm; the rotating speed of centrifugation is 8000 rpm, the washing solvent is methanol, and the washing times are three times; the temperature of vacuum drying of the obtained product is 60° C., and the drying time is 12 hours.

[0034] Step 2: Disperse a certain amount of cobalt salt and platinum salt into the solution, add ZIF-8 and mix thoroughly, the stirring reaction speed is 500rpm, and the stirring reaction time is 24h; the centrifugal separation speed is 8000rpm, and the washing solvent is deionized water, washing times three times; the obtained product was vacuum-dried at a temperature ...

Embodiment 1

[0039] (1) Synthesis of ZIF-8

[0040] 4.42g of zinc nitrate hexahydrate and 4.92g of 2-methylimidazole were dissolved in 25mL of methanol to form a clear solution. After the two solutions were uniformly mixed, they were reacted at 500 rpm for 24 hours; centrifuged at 8000 rpm, washed with methanol three times; and the product was vacuum-dried at 60° C. for 12 hours.

[0041] (2) Synthesis of PtCo@ZIF-8

[0042]Disperse 0.01g of potassium chloroplatinate and 0.75g of cobalt nitrate hexahydrate in 50mL of deionized water, while ZIF-8 crystal powder (0.65g) was dispersed in another 50mL of deionized water, and finally the two solutions were fully mixed and stirred for 24h . The product was washed three times with deionized water, and dried under vacuum at 60°C for 12 hours.

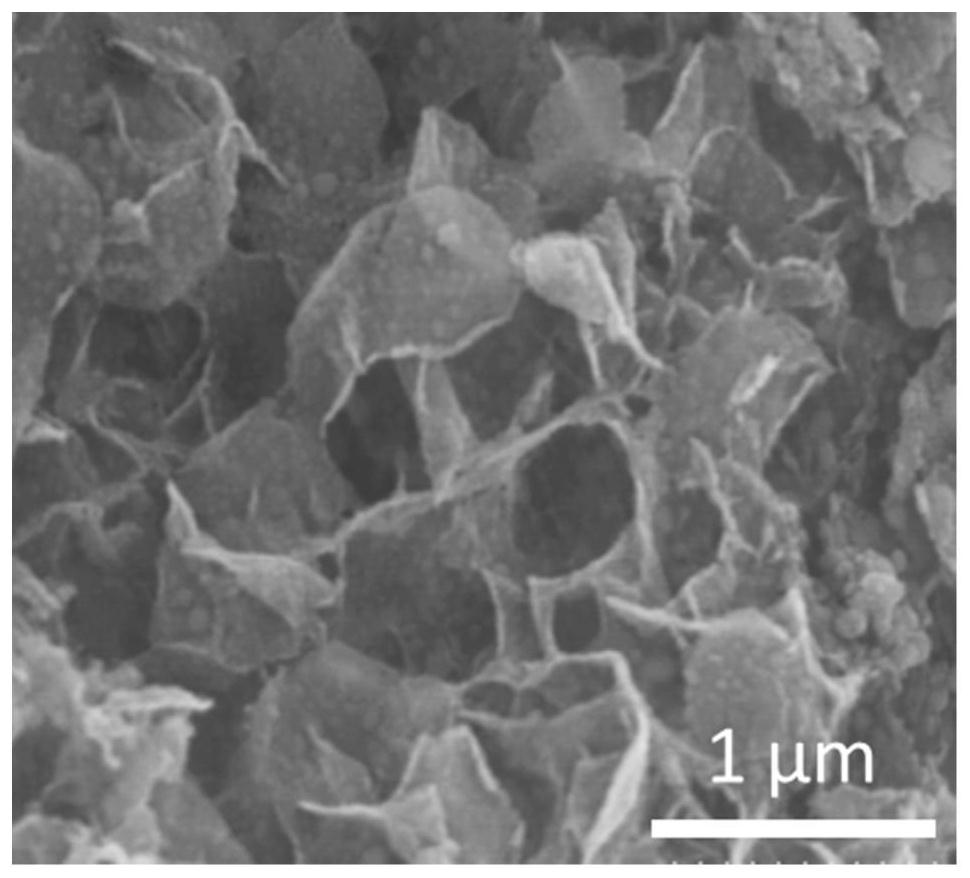

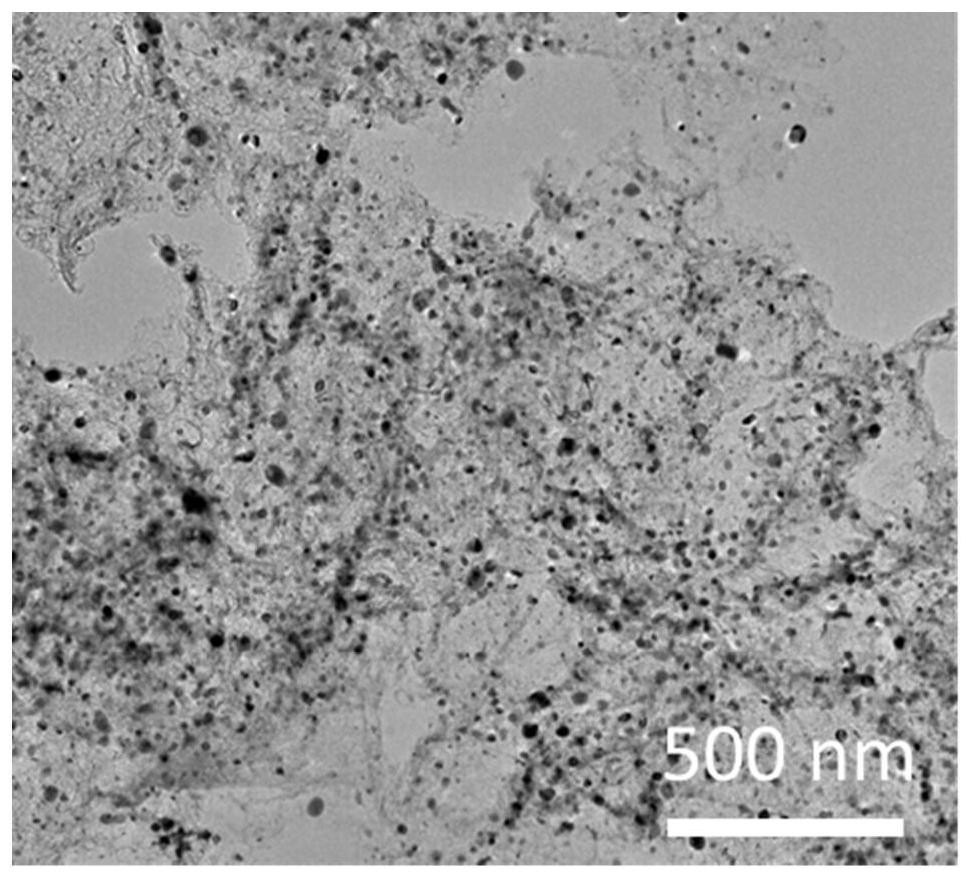

[0043] (3) Synthesis of PtCo@N-GNS

[0044] Weigh an appropriate amount of the above product and place it in a tube furnace, under the protection of nitrogen, raise the temperature to 800°C at a heating...

Embodiment 2

[0046] (1) Synthesis of ZIF-8

[0047] 4.42g of zinc nitrate hexahydrate and 4.92g of 2-methylimidazole were dissolved in 25mL of methanol to form a clear solution. After the two solutions were uniformly mixed, they were reacted at 500 rpm for 24 hours; centrifuged at 8000 rpm, washed with methanol three times; and the product was vacuum-dried at 60° C. for 12 hours.

[0048] (2) Synthesis of PtCo@ZIF-8

[0049] Disperse 0.01g of potassium chloroplatinate and 1.0g of cobalt nitrate hexahydrate in 50mL of deionized water, while ZIF-8 crystal powder (0.65g) was dispersed in another 50mL of deionized water, and finally the two solutions were fully mixed and stirred for 24h . The product was washed three times with deionized water, and dried under vacuum at 60°C for 12 hours.

[0050] (3) Synthesis of PtCo@N-GNS

[0051] Weigh an appropriate amount of the above product and place it in a tube furnace, under the protection of nitrogen, raise the temperature to 800°C at a heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com