Method for preparing hollow antimony-based binary alloy composite nanofiber material based on electrostatic spinning and potassium storage application of hollow antimony-based binary alloy composite nanofiber material

A composite nanofiber and electrospinning technology, which is applied in the manufacture of conductive/antistatic filaments, electrical components, rayon, etc., can solve the problems of Sb-based material crushing, achieve good cycle life, shorten the process flow, and improve Effect of Market Application Prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Weigh 20 mg of hydroxylated multi-walled carbon nanotubes and dissolve them in 10 ml of DMF to form a black solution after ultrasonication for 3 hours, then add 2 mmol of SbCl to the solution 3 and Ni(CH 3 COO) 2 ・4H 2 After O, stir at room temperature for 4 hours, then add a mixture of 0.7g polyacrylonitrile and 0.3g polymethyl methacrylate, heat at 60°C overnight and stir. The spinning solution was transferred into a 10 ml disposable syringe and then used for electrospinning. The propulsion speed is 50ul min -1 , the working voltage is set to 15KV, collected in aluminum foil, the needle type is 21G, and the distance from the needle to the collector is 18cm. After spinning for 8 hours, the fiber membrane was vacuum-dried overnight at 80° C. to fully evaporate the solvent. After drying, the nanofibrous membrane was exposed to Ar / H 2 In the atmosphere, start with 2 o Cmin -1 speed up to 280 oC Insulate for 3 hours for pre-carbonization to maintain the original s...

Embodiment 2

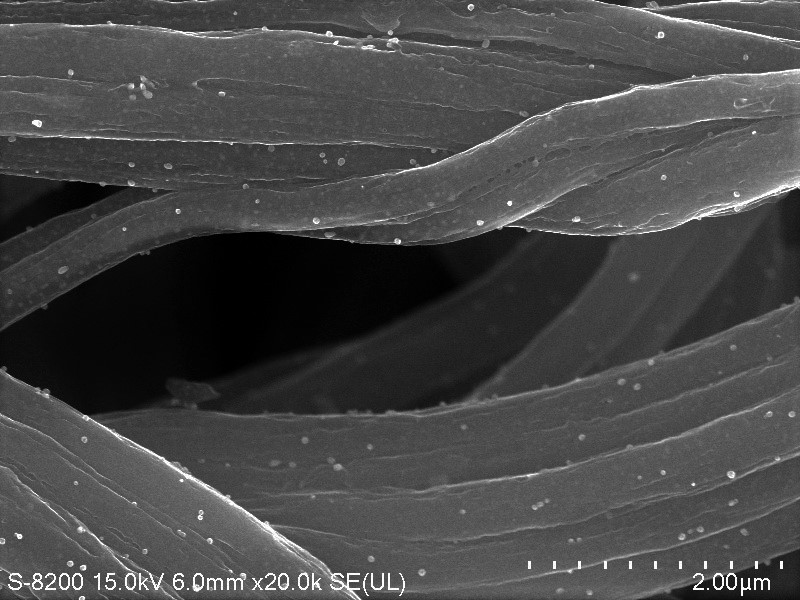

[0020] The method of the present embodiment is basically the same as that of embodiment 1, the difference is: the Ni(CH 3 COO) 2 ・4H 2 O to SnCl 2 , SnCl 2 and SbCl 3 The molar ratio is also 1:1. The collected samples are SnSb / CNT / PC composite nanofiber materials. Depend on figure 2 As shown in the SEM picture of the nanofiber, the diameter of the nanofiber is 200-300nm, and the surface is very smooth. The SnSb alloy particles are about 50nm, and agglomeration exists. The SnSb alloy particles are in the hollow channels inside the fibers. The presence of CNTs was not observed by SEM images, because the CNTs were well confined inside the carbon nanofibers.

Embodiment 3

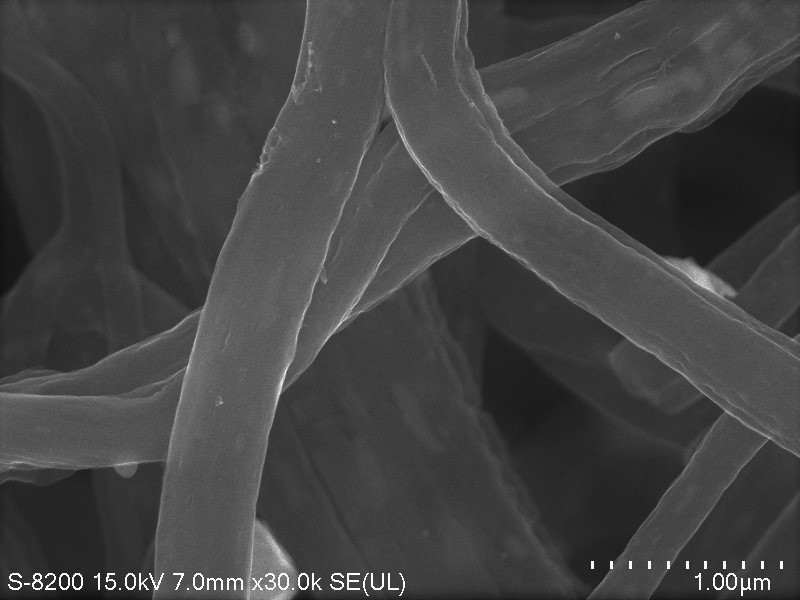

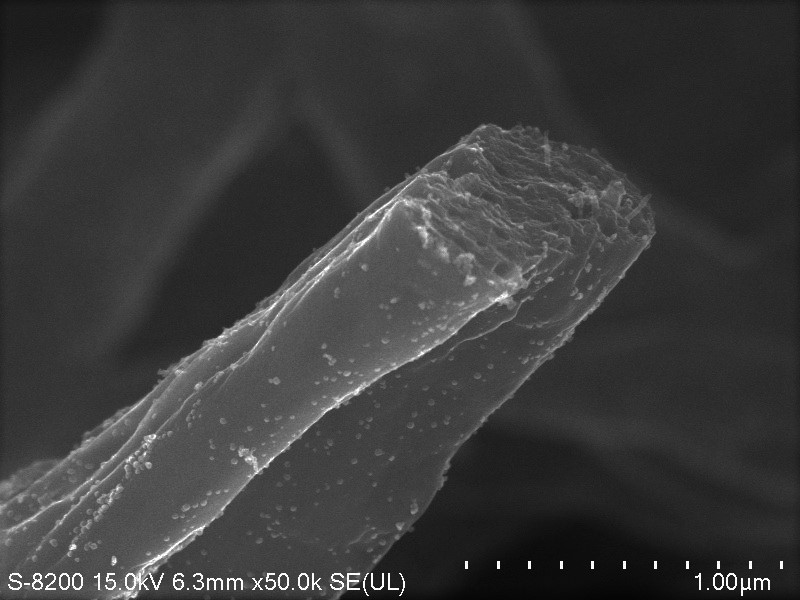

[0022] The method of the present embodiment is basically the same as that of embodiment 1, the difference is: the Ni(CH 3 COO) 2 ・4H 2 O to CoCl 2 , CoCl 2 and SbCl 3 The molar ratio is also 1:1. The collected samples are CoSb / CNT / PC composite nanofiber materials. Depend on image 3 As shown in the SEM picture of the nanofiber, the diameter of the nanofiber is several hundred nanometers, and the diameter of the CoSb nanoparticle is several nanometers. It can be clearly seen that the CoSb nanoparticle is evenly distributed on the inner and outer surfaces of the carbon fiber, and it can be seen that the interior of the fiber is a hollow structure. This is because PMMA is produced by pyrolysis during calcination. The CNTs are exposed outside the hollow channels, forming a well-conducting network.

[0023] The crystal structure of the XSb (X=Ni, Sn, Co) / CNT / PC composite nanofiber material of the present invention is characterized by using XRD technology as Figure 4 shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com