3D printing composite stent as well as preparation method and application thereof

A composite scaffold and 3D printing technology, applied in the fields of materials science and medicine, to achieve the effect of improving the quality of bone repair, excellent elasticity and toughness, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

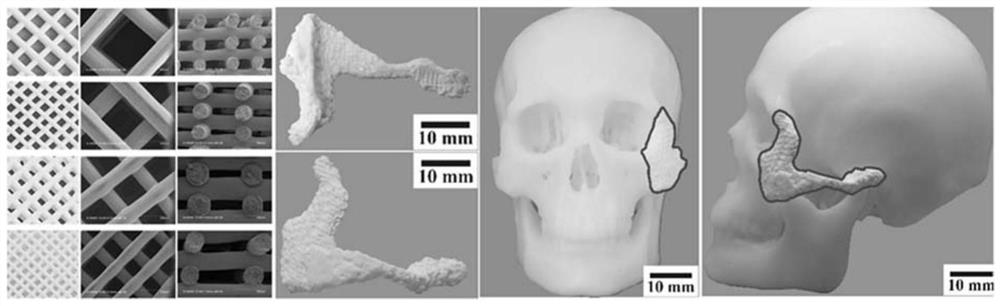

[0083] The preparation method of the 3D printing composite support provided by the present invention, the preparation method comprises the following steps:

[0084] (i) Provide PEGylated polyglyceryl sebacate prepolymer (PEGS prepolymer), β-tricalcium phosphate (β-TCP) nanoparticles, hexamethylene isocyanate (HDI), 2-ethylhexanoic acid Tin II and solvents;

[0085] (ii) Dissolving the PEGS prepolymer in a solvent, adding stannous 2-ethylhexanoate (Tin II), HDI and β-TCP nanoparticles in sequence and stirring evenly to obtain a bioink;

[0086] (iii) The above-mentioned bio-ink is quickly transferred into the three-dimensional printing barrel, and the three-dimensional scaffold is printed, and then transferred to a vacuum dryer for further cross-linking and curing,

[0087] Wherein, the solvent is selected from the following group: one or more of N,N-dimethylformamide, N,N-dimethylacetamide, tetrahydrofuran, dimethyl sulfoxide, and dioxane Mixed solvents.

[0088] Wherein, t...

Embodiment 1

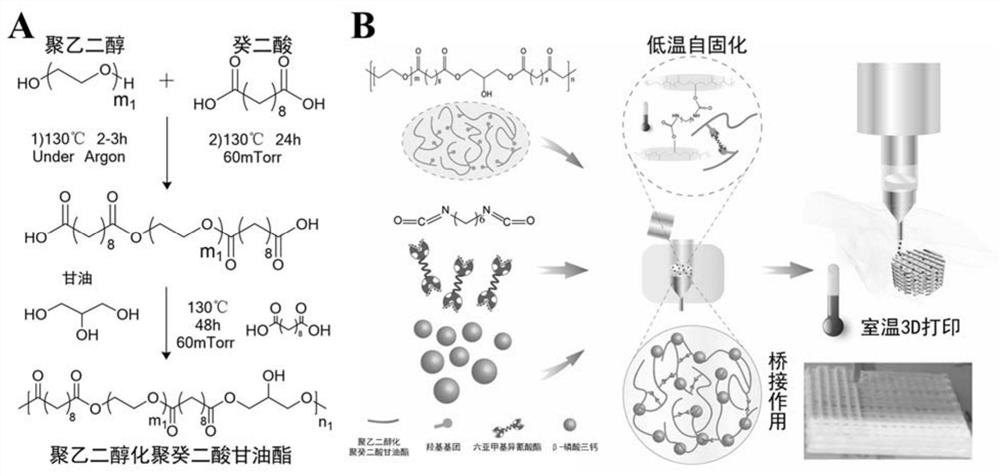

[0106] This embodiment relates to the synthesis and purification of PEGS and the mechanism diagram of 3D printing scaffold

[0107] Synthetic route such as figure 1 As shown in A, it specifically includes the following steps:

[0108] (a) Weigh 20.23g of sebacic acid and 20.00g of PEG (the number average molecular weight is 1000g / mol) in an argon atmosphere, melt and react at 130°C for 2 hours;

[0109] (b) continue to react the product of step (a) at 130° C. under vacuum conditions for 24 hours to obtain a linear prepolymer of sebacic acid and PEG;

[0110] (c) Add 7.36 g of glycerol and 8.09 g of sebacic acid to the product of step (b), and continue the reaction at 130° C. under vacuum for 48 hours. In this reaction, the molar content of PEG relative to glycerol was 20%, and the molar ratio of hydroxyl and carboxyl groups in the total reaction was 1:1.

[0111] (d) Purify the prepolymer by ethanol dissolution-ultrapure water dialysis to remove unreacted monomers and small...

Embodiment 2

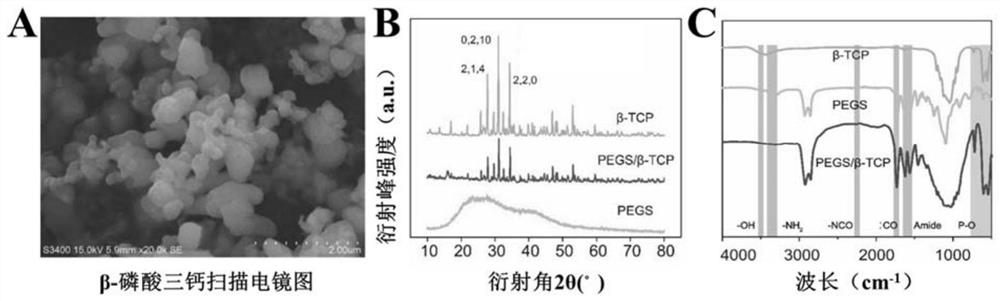

[0114] This example relates to the synthesis of β-TCP nanoparticles

[0115] Prepare β-TCP nanoparticles by wet chemical precipitation method, the specific steps are:

[0116] (a) Under continuous stirring, 0.6mol / L Ca(NO 3 ) 2 ·H 2 O solution was added dropwise to 0.4mol / L (NH 4 ) 2 HPO 4 solution;

[0117] (b) During the reaction, monitor the pH change of the solution in step (a) with a pH meter, and add a certain amount of NH 3 ·H 2 O to keep the pH range controlled at 7.1-7.5;

[0118] (c) continue stirring for 1 hour after the dropwise addition, and leave the product of step (b) at room temperature overnight;

[0119] (d) The precipitate was obtained by suction filtration using a Buchner funnel, washed three times with ultrapure water and twice with ethanol, and dried at 80° C. for 48 hours.

[0120] (e) Place the dried product of step (d) in a muffle furnace and calcinate at 800° C. for 2 hours at a heating rate of 5° C. / min to finally obtain nano-sized β-TCP p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com