Method for efficiently separating straw components by adopting novel eutectic solvent

A low eutectic solvent, a new type of technology, applied in the use of microorganism/enzyme cellulose treatment, textiles and papermaking, papermaking, etc., can solve the problems affecting high-value utilization, narrow utilization window, small molecular weight of lignin, etc., to achieve value-added The effect is obvious, the utilization rate of raw materials is high, and the effect of high-efficiency removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040]The method for efficiently separating straw components using a novel deep eutectic solvent comprises the following steps:

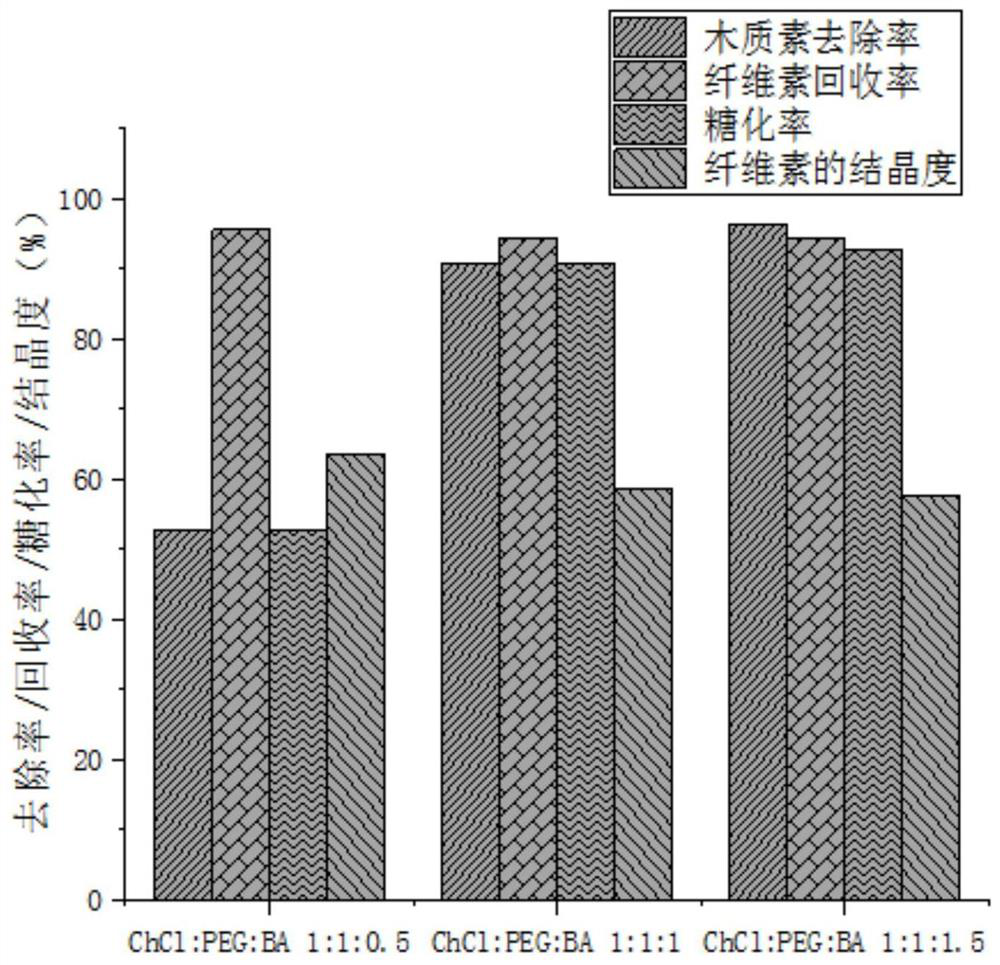

[0041] (1) Synthesis of novel deep eutectic solvent: choline chloride, polyethylene glycol-200 and boric acid are synthesized novel deep eutectic solvent as shown in Table 2, can be used directly without purification;

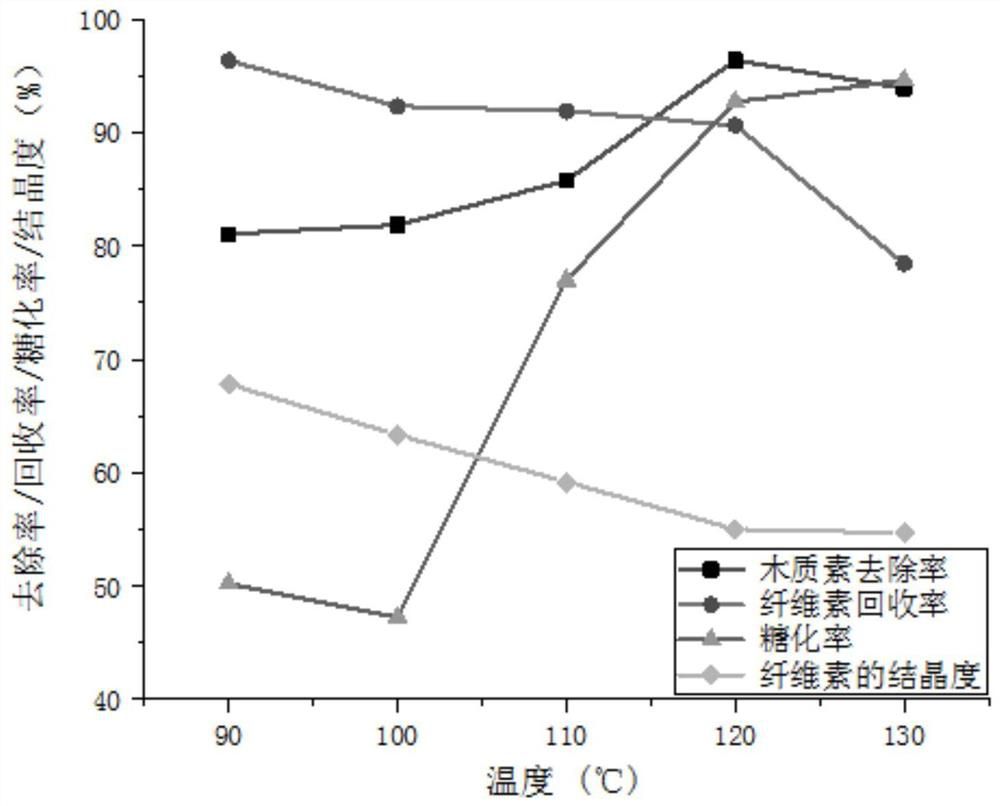

[0042] (2) Primary treatment of straw: first, mix straw and deionized water according to the solid-to-liquid ratio of 1:15, and react at 120°C for 0.5h; then perform solid-liquid separation to obtain filtrate I and filter residue I, and use filter residue I Washing with ion water for 2-3 times, drying to absolute dryness to obtain the straw residue of primary treatment;

[0043] (3) Extraction of hemicellulose: add ethanol in the filtrate I of step (2) gained, wherein the volume ratio of ethanol and filtrate I is 5:1; The hemicellulose is obtained; the ethanol filtrate obtained by filtering is rotary evaporated and recycled;

[004...

Embodiment 2

[0054] The method for efficiently separating straw components using a novel deep eutectic solvent comprises the following steps:

[0055] (1) Synthesis of a new type of deep eutectic solvent: mix choline chloride, polyethylene glycol-200 and boric acid at a molar ratio of 1:1:1.5, and react at 80°C for 1 hour to obtain a new type of deep eutectic solvent , can be used directly without purification;

[0056] (2) Primary treatment of straw: first, mix straw and deionized water according to the solid-to-liquid ratio of 1:15, and react at 120°C for 0.5h; then perform solid-liquid separation to obtain filtrate I and filter residue I, and use filter residue I Washing with ion water for 2-3 times, drying to absolute dryness to obtain the straw residue of primary treatment;

[0057] (3) Extraction of hemicellulose: add ethanol in the filtrate I of step (2) gained, wherein the volume ratio of ethanol and filtrate I is 5:1; The hemicellulose is obtained; the ethanol filtrate obtained ...

Embodiment 3

[0065] The method for efficiently separating straw components using a novel deep eutectic solvent comprises the following steps:

[0066] (1) Synthesis of a new type of deep eutectic solvent: mix choline chloride, polyethylene glycol-200 and boric acid at a molar ratio of 1:1:1.5, and react at 80°C for 1 hour to obtain a new type of deep eutectic solvent , can be used directly without purification;

[0067] (2) Primary treatment of straw: first, mix straw and deionized water according to the solid-to-liquid ratio of 1:15, and react at 120°C for 0.5h; then perform solid-liquid separation to obtain filtrate I and filter residue I, and use filter residue I Washing with ion water for 2-3 times, drying to absolute dryness to obtain the straw residue of primary treatment;

[0068] (3) Extraction of hemicellulose: add ethanol in the filtrate I of step (2) gained, wherein the volume ratio of ethanol and filtrate I is 5:1; The hemicellulose is obtained; the ethanol filtrate obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com