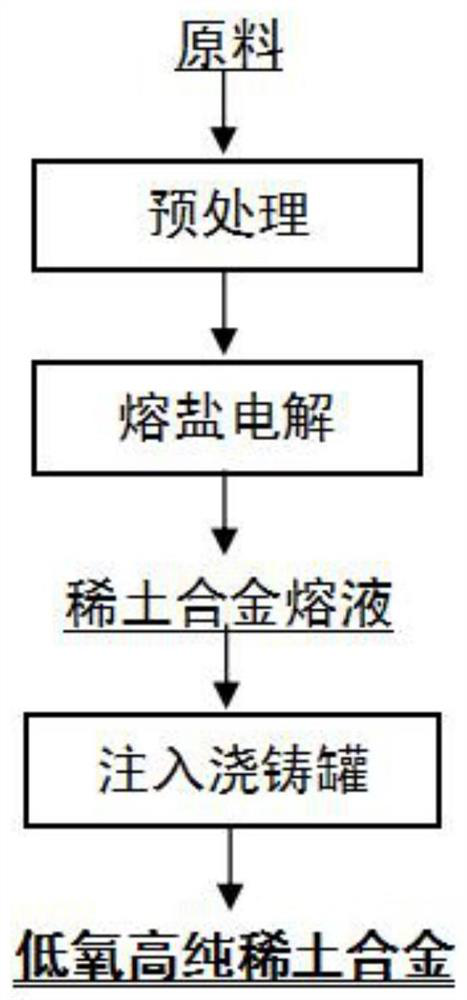

Preparation method of low-oxygen high-purity rare earth alloy

A rare earth alloy, high oxygen technology, applied in the direction of cells, electrolysis process, electrolysis components, etc., can solve the problems of high performance materials, high oxygen content and high oxygen content in rare earth alloys, and achieve simplified operation, low oxygen content, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for preparing a low-oxygen high-purity lanthanum-iron alloy, comprising the following steps:

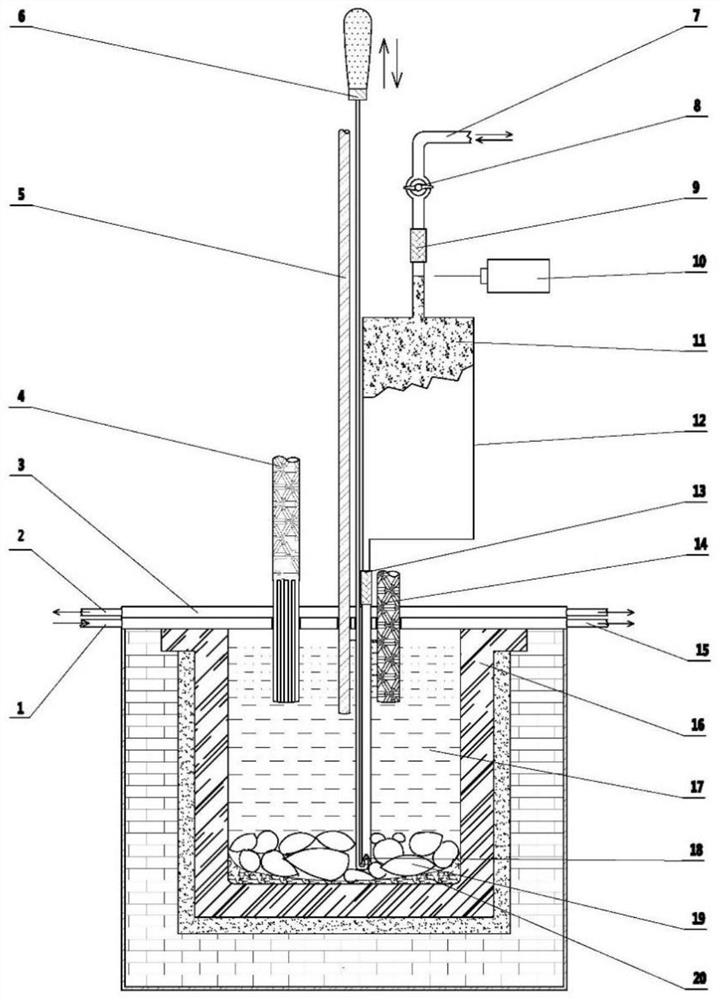

[0034] 1. The newly prepared lanthanum oxide with a purity of 99.98% is used as a raw material, and is added to a fluoride electrolysis system for molten salt electrolysis. The purity of the electrolyte lanthanum fluoride, lithium fluoride, and barium fluoride is all greater than 99.5%, and the cathode of the electrolytic cell is pure iron The anode is a fluted graphite rod, and a pair of graphite heating rods are provided. The temperature of the electrolysis process is controlled at 950°C, the cell voltage is 14V, and the cathode current density is 8A / cm 2 , anode current density 1.5A / cm 2 , the cathode (pure iron rod) is continuously consumed by itself and interdiffused with the precipitated lanthanum metal to form a lanthanum-iron alloy, which is collected at the bottom of the electrolytic cell.

[0035] 2. After 90 minutes of electrolysis, take a carbon steel cast...

Embodiment 2

[0040] A method for preparing a low-oxygen high-purity lanthanum-iron alloy, comprising the following steps:

[0041] 1. Using lanthanum oxide with a purity of 99.95% as the raw material, dehydration at 500°C for 180 minutes for pretreatment, then adding a fluoride electrolysis system for molten salt electrolysis, the purity of the electrolyte lanthanum fluoride and lithium fluoride is greater than 99.5%, The cathode of the electrolytic cell is a pure iron rod, the anode is a fluted graphite rod, and a pair of graphite heating rods are provided. The temperature of the electrolysis process is controlled at 970°C, the cell voltage is 13V, and the cathode current density is 7A / cm 2 , anode current density 1.2A / cm 2 , the cathode (pure iron rod) is continuously consumed by itself and interdiffused with the precipitated lanthanum metal to form a lanthanum-iron alloy, which is collected at the bottom of the electrolytic cell.

[0042] 2. After electrolysis for 100 minutes, take a ...

Embodiment 3

[0047] A method for preparing a low-oxygen high-purity praseodymium-neodymium-iron alloy, comprising the following steps:

[0048] 1. Using the newly prepared mixed chloride of praseodymium and neodymium as raw material, the mass ratio of praseodymium and neodymium is 1:3, adding the chloride electrolysis system for molten salt electrolysis, the purity of praseodymium chloride, neodymium chloride and potassium chloride is all greater than 99.5%. The cathode of the electrolytic cell is a pure iron rod, the anode is a fluted graphite rod, and a pair of graphite heating rods are provided. The temperature of the electrolysis process is controlled at 850°C, the cell voltage is 12V, and the cathode current density is 6A / cm 2 , anode current density 1A / cm 2 , The cathode (pure iron rod) is continuously consumed and interdiffused with the precipitated praseodymium neodymium metal to form a praseodymium neodymium iron alloy, which is collected at the bottom of the electrolytic cell. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com