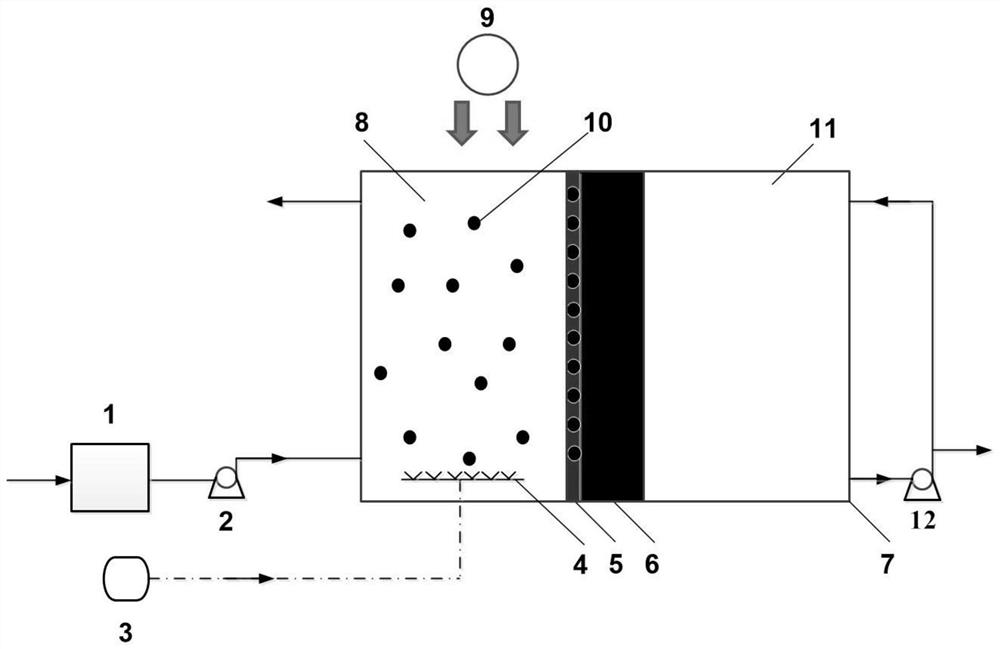

Composite catalytic membrane, and photo-catalytic oxidation-membrane distillation multi-dimensional sewage disposal system and disposal method

A sewage treatment system, photocatalytic oxidation technology, applied in the directions of oxidized water/sewage treatment, light water/sewage treatment, water/sewage treatment, etc., can solve problems such as the inability to completely eliminate pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] The present invention also provides a kind of method for preparing above-mentioned composite catalytic membrane, and described preparation method specifically comprises the following steps:

[0074] (1) Preparation of superhydrophobic base film 6 by electrospinning method: dissolve PEO (polyethylene oxide) in deionized water, and stir at constant temperature to obtain transparent solution A; quickly stir hydrophobic film material and A solution at room temperature to obtain spun Silk liquid B; put the spinning liquid B into the syringe, set the operating parameters of the electrospinning, start spinning, and control the thickness of the PTFE super-hydrophobic membrane by the time of the electrospinning.

[0075] (2) Preparation of composite catalytic membrane by electrospinning method: dissolve photocatalyst powder, PEO and hydrophobic membrane material in a solvent in a certain proportion, stir to obtain spinning solution, and obtain superhydrophobic base membrane in st...

Embodiment 1

[0083] This embodiment provides a TiO 2 The preparation method of / PTFE composite catalytic membrane, described preparation method comprises the steps:

[0084] (1) Preparation of PTFE superhydrophobic base film by electrospinning method: Dissolve PEO (polyethylene oxide) in deionized water and stir at 20°C for 4 hours to obtain a transparent solution A; fix the mass ratio of PEO and PTFE to 1:10 , take the corresponding PTFE emulsion and A solution, stir rapidly at 20°C for 3 hours to obtain the spinning solution B; put the spinning solution B into a syringe, and prepare for spinning. The operating conditions of electrospinning are set as: voltage 20kV, drum speed 1000rpm, spinning solution B feeding speed is 0.5mL / h, and the thickness of the PTFE superhydrophobic membrane is controlled by the time of electrospinning;

[0085] (2) Preparation of TiO by electrospinning 2 / PTFE composite catalytic membrane: the mass ratio of fixed catalyst, PEO and PTFE is 0.2:1:10, and TiO 2...

Embodiment 2

[0087] This embodiment provides a C 3 N 4 The preparation method of / PVDF composite catalytic film, described preparation method comprises the steps:

[0088] (1) Preparation of PVDF superhydrophobic base film by electrospinning method: Dissolve PEO (polyethylene oxide) in deionized water and stir at 40°C for 3 hours to obtain a transparent solution A; fix the mass ratio of PEO and PVDF to 1:10 , take PVDF emulsion and A solution, stir rapidly at 40°C for 2 hours to obtain spinning solution B; put spinning solution B into a syringe, and prepare for spinning. Set the operating conditions of electrospinning as follows: voltage 10kV, drum speed 500rpm, spinning solution B feed rate 0.3mL / h, the thickness of the PTFE superhydrophobic membrane is controlled by the time of electrospinning;

[0089] (2) Preparation of C by electrospinning 3 N 4 / PVDF composite catalytic membrane: the mass ratio of fixed catalyst, PEO and PTFE is 0.3:1:10, and C 3 N 4 The photocatalyst powder, PE...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com