Preparation method of multilayer-polymer surface functional modified electronic fiber cloth flexible high-frequency CCL (copper-clad laminate)

A surface function modification and fabric flexibility technology, applied in electronic equipment, circuit substrate materials, chemical instruments and methods, etc., can solve the problem of low bending strength, poor adhesion of outer copper foil, high glass transition temperature, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

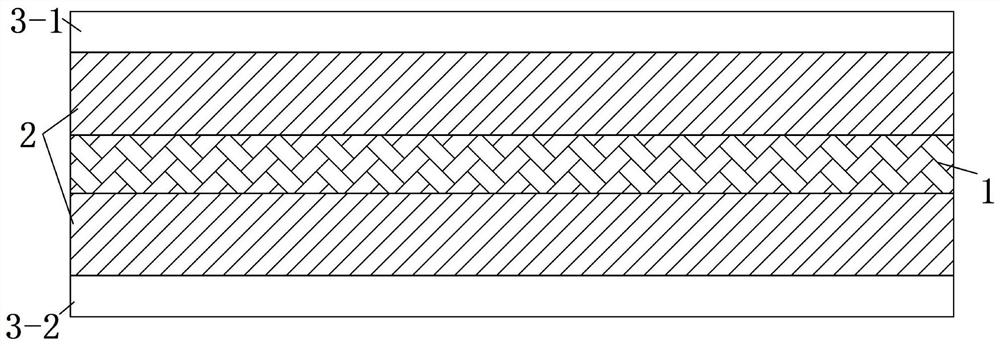

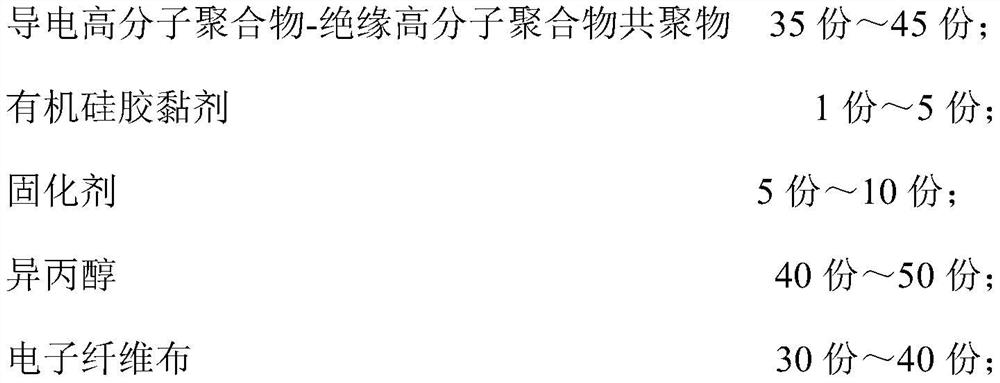

[0054] This embodiment provides a flexible high-frequency copper-clad laminate with multi-layer polymerized surface functionally modified electronic fiber cloth, including a graphene oxide metallized reinforced nanofiber layer 1 located in the middle layer, and a graphene oxide metallized reinforced nanofiber layer located in the middle layer. The polypyrrole-polyethylene terephthalate copolymer coated electronic fiber cloth layer 2 on both sides of 1 and the two sides of the polypyrrole-polyethylene terephthalate copolymer coated electronic fiber cloth layer 2 The first copper foil layer 3-1 and the second copper foil layer 3-2.

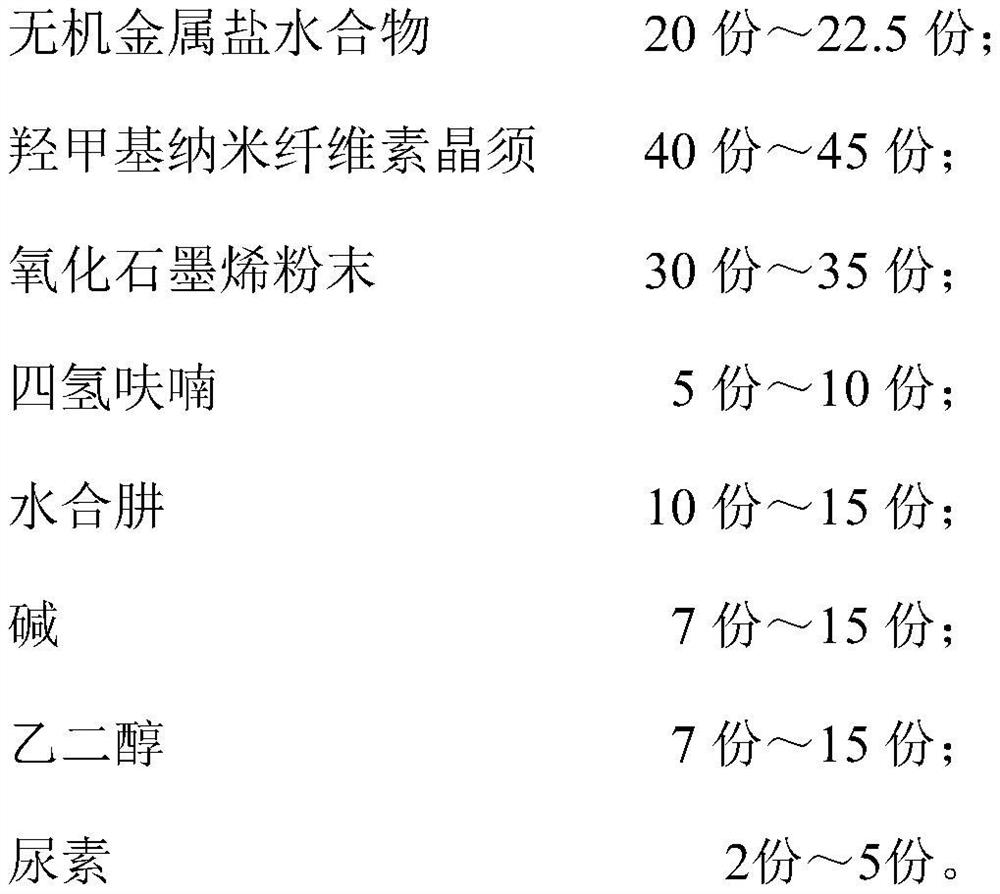

[0055] Wherein, graphene oxide metallized reinforced nanofibers, by weight components, include the following components:

[0056]

[0057]

[0058] Wherein, the preparation method of graphene oxide metallization reinforced nanofiber comprises the following steps:

[0059] B1: 30 parts of graphene oxide powder are ultrasonically dissolved in 3...

Embodiment 2

[0091] This embodiment provides a flexible high-frequency copper-clad laminate with multi-layer polymerized surface functionally modified electronic fiber cloth, including a graphene oxide metallized reinforced nanofiber layer 1 located in the middle layer, and a graphene oxide metallized reinforced nanofiber layer located in the middle layer. 1 The poly(3-butylthiophene)-polyurethane copolymer coated electronic fiber cloth layer 2 on both sides and the first copper on both sides of the poly(3-butylthiophene)-polyurethane copolymer coated electronic fiber cloth layer 2 foil layer 3-1 and a second copper foil layer 3-2.

[0092] Wherein, graphene oxide metallized reinforced nanofibers, by weight components, include the following components:

[0093]

[0094] A method for preparing graphene oxide metallized reinforced nanofibers, comprising the following steps:

[0095] B1: 35 parts of graphene oxide powder are ultrasonically dissolved in 7.5 parts of ethylene glycol at a fr...

Embodiment 3

[0126] This embodiment provides a flexible high-frequency copper-clad laminate with multi-layer polymerized surface functionally modified electronic fiber cloth, including a graphene oxide metallized reinforced nanofiber layer 1 located in the middle layer, and a graphene oxide metallized reinforced nanofiber layer located in the middle layer. The polyacetylene-polyvinyl alcohol copolymer coated electronic fiber cloth layer 2 on both sides of 1 and the first copper foil layer 3-1 and the second copper foil layer 3-1 on both sides of the polyacetylene-polyvinyl alcohol copolymer coated electronic fiber cloth layer 2 Copper foil layer 3-2.

[0127] Wherein, graphene oxide metallized reinforced nanofibers, by weight components, include the following components:

[0128]

[0129] A method for preparing graphene oxide metallized reinforced nanofibers, comprising the following steps:

[0130] B1: 32.5 parts of graphene oxide powder were ultrasonically dissolved in 5.5 parts of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com