Solid electrolyte membrane, solid lithium ion battery and preparation method of solid lithium ion battery

A solid-state electrolyte membrane and lithium-ion battery technology, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, solid electrolytes, etc., can solve the problems of unstable sulfide structure, poor interface performance, and many side reactions, and achieve enhanced strength , lower impedance, better stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

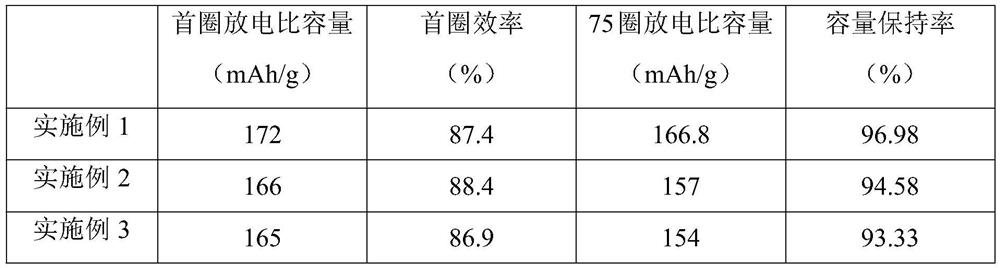

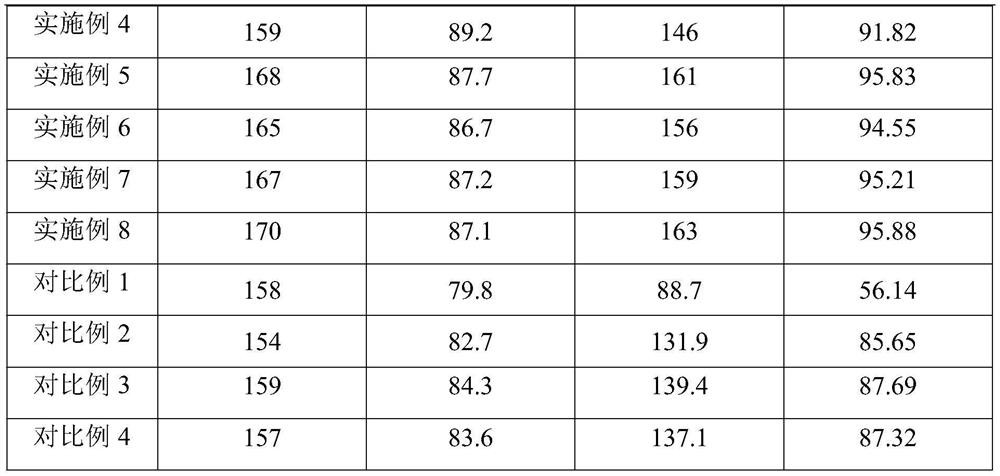

Examples

preparation example Construction

[0046] 3. Preparation method of solid-state lithium-ion battery

[0047] A third aspect of the present invention provides a method for preparing a solid-state lithium-ion battery, comprising the following steps:

[0048] Take polyvinylidene fluoride with a molecular weight between 600,000 and 1,200,000, place it in lye and react at 50 to 70°C, stir continuously during the reaction, then repeatedly wash with deionized water and absolute ethanol, and dry to obtain a Alkali-washed and dried polyvinylidene fluoride;

[0049] Adding alkali-washed and dried polyvinylidene fluoride, in-situ polymerization monomers and initiators to the first organic solvent, and polymerizing in a nitrogen atmosphere at 60-80°C to form a homogeneous solution;

[0050] adding a small amount of fast ion conductor powder to the homogeneous solution several times, adding lithium salt, stabilizer and dispersant at the same time, and stirring to form a uniform slurry;

Embodiment 1

[0057] Preparation of solid electrolyte membrane:

[0058] 1) Take polyvinylidene fluoride with a molecular weight between 600,000 and 1,200,000, place it in lye and react at 50 to 70°C for 4 hours, stir continuously during the reaction, then repeatedly wash with deionized water and absolute ethanol, and dry That is, polyvinylidene fluoride that has been washed and dried by alkali;

[0059] 2) Add 5wt% polyvinylidene fluoride, 4.5wt% polyethylene glycol diacrylate (Mn=1000), 1wt% vinyl n-butyl ether and 0.055wt% AIBN initiator through alkaline washing and drying to the DMF solvent, Polymerize in a nitrogen atmosphere at 60-80°C for 8 hours to form a homogeneous solution;

[0060] 3) 15wt% garnet-type LLZO (Li 7 La 3 Zr 2 o 12 ) powder was added to the homogeneous solution several times in a small amount, and 10wt% LiTFSI, 0.02wt% citric acid and 0.025wt% dispersant BYK-180 were added at the same time, first ultrasonically stirred for 6 hours, and then rapidly stirred for ...

Embodiment 2

[0069] The difference with embodiment 1 is:

[0070] Preparation of solid electrolyte membrane:

[0071]1) Take polyvinylidene fluoride with a molecular weight between 600,000 and 1,200,000, place it in lye and react at 50 to 70°C for 4 hours, stir continuously during the reaction, then repeatedly wash with deionized water and absolute ethanol, and dry That is, polyvinylidene fluoride that has been washed and dried by alkali;

[0072] 2) Add 5wt% polyvinylidene fluoride, 4.5wt% butyl acrylate, 1wt% polyethylene glycol methacrylate and 0.055wt% AIBN initiator after alkaline washing and drying to the DMF solvent, at 60-80°C Polymerize in a nitrogen atmosphere for 8 hours to form a homogeneous solution;

[0073] 3) 15wt% garnet-type LLZO (Li 7 La 3 Zr 2 o 12 ) powder was added to the homogeneous solution several times in a small amount, and 10wt% LiTFSI, 0.02wt% citric acid and 0.025wt% dispersant BYK-180 were added at the same time, first ultrasonically stirred for 6 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com