Ship tail gas purification device and process for strengthening SO2 absorption and oxidation through segmented temperature self-adaptive precise regulation and control

A technology of ship exhaust gas and segmented temperature, which is applied in gas treatment, separation method, dispersed particle separation, etc. Changes in flow and other problems, to reduce seawater consumption, achieve reuse, good self-adaptive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

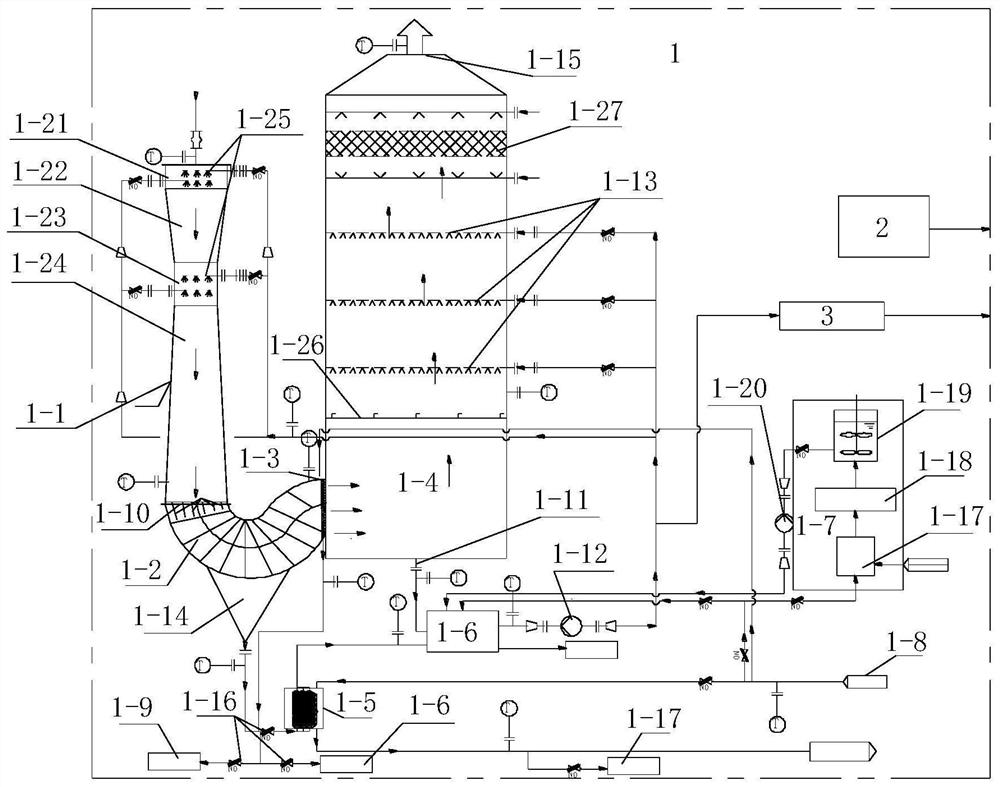

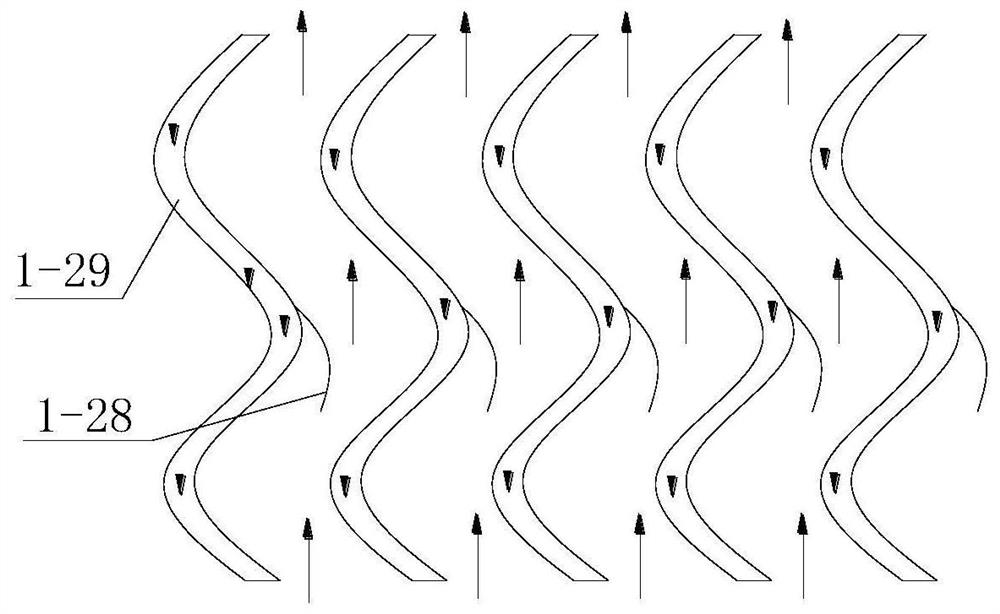

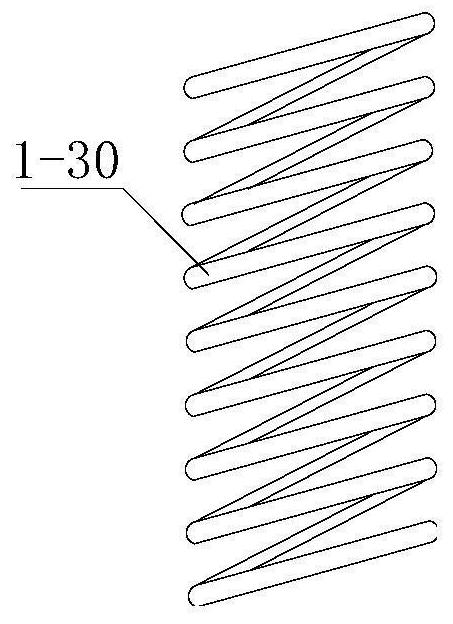

[0061] refer to Figure 1-7 , a step-by-step temperature self-adaptive and precise regulation of enhanced SO 2 An absorption-oxidation ship tail gas purification device, the device includes a ship tail gas purification system 1, a gas-liquid phase temperature control system 2, and a desulfurizer intelligent metering and distribution system 3, and the ship tail gas purification system 1 is respectively a gas-liquid phase temperature control system 2. The desulfurization agent intelligent metering and distribution system 3 is connected, and the gas-liquid phase temperature control system 2 is connected with the desulfurizing agent intelligent metering and distribution system 3; the ship tail gas purification system includes Venturi cooling tower 1-1, U-shaped soda Separation device 1-2, condensing dehumidification device 1-3, flue gas scrubber 1-4, liquid-liquid heat exchanger 1-5, circulation tank 1-6, desulfurizer preparation and storage system 1-7, seawater supply Systems 1-...

Embodiment 2

[0097] This embodiment takes a 10,000-ton ocean-going freighter as an example. The ocean-going freighter sails in a seawater high temperature area (30°C), the pH of the seawater is 7.8, the power of the fuel engine is 320kW, the fuel is III diesel, the exhaust gas temperature is 230°C, and the smoke volume is 3000m 3 / h,SO 2 The concentration is 1200μL / L (the design value is 1500μL / L), the Venturi cooling tower is equipped with 4 spray layers, and the flue gas scrubber is equipped with 3 spray layers, a flow equalization efficiency plate and a demister.

[0098] Its specific implementation process is:

[0099] The tail gas generated during the ship's navigation enters the Venturi cooling tower. Since the pH of seawater is 7.8, seawater is used as the desulfurizer, and the desulfurization efficiency of the system only reaches 94.5%, and the SO 2 The emission concentration is about 66μL / L, which does not meet the emission requirements. If magnesium oxide is used as a desulfuriz...

Embodiment 3

[0104]This embodiment takes a 10,000-ton ocean-going freighter as an example. The ocean-going freighter sails in a seawater high temperature area (40°C), the pH of the seawater is 7.5, the power of the fuel engine is 350kW, the fuel is III diesel, the exhaust gas temperature is 370°C, and the smoke volume is 3600m 3 / h,SO 2 The concentration is 1500μL / L (the design value is 1500μL / L), the Venturi cooling tower is equipped with 4 spray layers, the flue gas scrubber is equipped with 3 spray layers, a layer of flow equalization efficiency plate and a layer of demister.

[0105] Its specific implementation process is:

[0106] The tail gas generated during the ship's navigation enters the Venturi cooling tower. Since the pH of seawater is 7.5, seawater is used as the desulfurizer, and the desulfurization efficiency of the system only reaches 92.3%, and the SO 2 The emission concentration is about 115μL / L, which does not meet the emission requirements. If magnesium oxide is used a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com